Preparation method of high-expansion liquid absorption sponge

A high-expansion, sponge technology, applied in the field of biomedical materials, can solve the problem of high difficulty in cell uniformity, and achieve the effect of simple and easy preparation method, good fluidity and easy pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

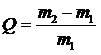

Method used

Image

Examples

Embodiment 1

[0019] Add 5g of PVA-1799 and 50g of water into a three-necked flask with stirring, and heat to 85°C until completely dissolved. Then lower the temperature to 60°C, add 15 g of 18% (mass percentage, the same below) hydrochloric acid and 5 g of 37% (mass percentage, the same below) aqueous formaldehyde solution under stirring, and react at 60°C for 50 minutes.

[0020] Add 50g of PVA-1799 and 500g of water into another three-necked flask, heat to dissolve until clear, then lower the temperature to 60°C, add 150g of 18% hydrochloric acid and 50g of 37% formaldehyde solution under stirring. Stirring was continued for 2 minutes at 60°C.

[0021] The above two liquids were mixed together, and the reaction was continued at 60° C. for 10 minutes.

[0022] Pour the reacted material liquid into the mold, place it in an oven at 65°C and keep it warm for 12 hours, then remove the mold and wash it to obtain a clean sponge body, which is frozen below 0°C and cut into samples of specific s...

Embodiment 2

[0030] Add 5g of PVA-1799 and 50g of water into a three-necked flask with stirring, and heat to 85°C until completely dissolved. Then the temperature was lowered to 60°C, 15 g of 18% hydrochloric acid and 4.5 g of 37% formaldehyde aqueous solution were added under stirring, and the reaction was carried out at 60°C for 50 minutes.

[0031] Add 50g of PVA-1799 and 500g of water into another three-neck flask, heat to dissolve until clear, then lower the temperature to 60°C, add 150g of 18% hydrochloric acid and 45g of 37% formaldehyde aqueous solution while stirring. Stirring was continued for 10 minutes at 60°C.

[0032] The above two liquids were mixed together, and the reaction was continued at 60° C. for 20 minutes.

[0033] Pour the reacted material liquid into the mold, put it in an oven at 65°C and keep it warm for 12 hours, then remove the mold and wash to obtain a clean sponge body, which is frozen below 0°C and cut into samples of specific shapes. It is 8cm long, 2cm ...

Embodiment 3

[0037] Add 5g of PVA-1799 and 60g of water into a three-necked flask with stirring, and heat to 85°C until completely dissolved. Then lower the temperature to 50°C, add 16 g of 18% hydrochloric acid and 5 g of 37% formaldehyde aqueous solution under stirring, and react at 50°C for 50 minutes.

[0038] Add 100g of PVA-1799 and 1200g of water into another three-neck flask, heat to dissolve until clear, then lower the temperature to 50°C, add 320g of 18% hydrochloric acid and 100g of 37% formaldehyde solution under stirring. Stirring was continued for 10 minutes at 50°C.

[0039] The above two materials were mixed together, and the reaction was continued at 50° C. for 20 minutes.

[0040] Pour the reacted material liquid into the mold, put it in an oven and keep it warm at 65°C for 11 hours, then demould and wash to obtain a clean sponge body, which is frozen below 0°C and cut into samples of specific shapes. It is 8cm long, 2cm wide, and 1.5cm thick.

[0041] After the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com