Boron magnesium prealloy powder material, and preparation method thereof

A technology of pre-alloyed powder and bulk material, applied in the field of metal-based combustibles, can solve the problems of reducing the exothermic heat of oxidation reaction, increasing the active boron content, reducing the reactivity of boron powder, etc. Reduce the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Pretreatment: put boron powder in absolute ethanol (B:C 2 h 5 OH=1g:4mL) soaked for 12h, filtered with suction, and dried in vacuum.

[0039] (2) Mechanical premixing: Weigh atomized magnesium powder and pretreated boron powder at a molar ratio of 1:4, stir in a vacuum planetary mixer, and then add them to a three-dimensional mixer for premixing for 1 hour to obtain a mixed powder .

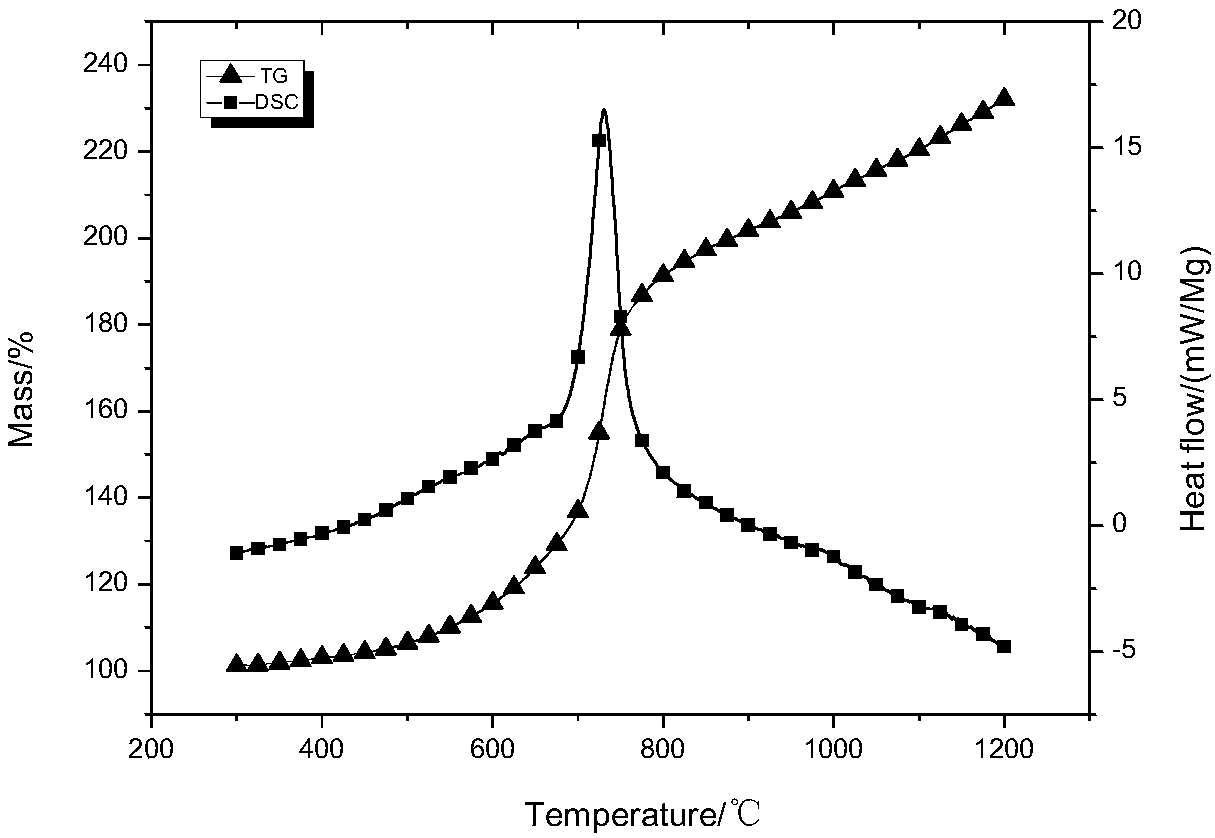

[0040] (3) High-temperature uniform premixing: put the mixed powder in a stainless steel crucible, put it into a tube furnace, evacuate to 500Pa, keep the pressure for 1h, and then fill it with high-purity argon to 2000Pa. Afterwards, high-temperature uniform premixing is carried out, the heating rate is 10°C / min, the sintering temperature is 600°C, and the temperature is kept for 3 hours. After cooling to below 50°C with the furnace, the sintered block is taken out and put into an ultrafine pulverizer under the protection of high-purity argon. Under mechanical crushing and grinding...

Embodiment 2

[0048] (1) Pretreatment: Put boron powder in ethyl acetate (B:C 4 h 8 o 2 =1g:6mL) soaked for 24h, filtered with suction, and dried in vacuum.

[0049] (2) Uniform premixing: Weigh the atomized magnesium powder and pretreated boron powder at a molar ratio of 1:7, add them to a three-dimensional mixer for premixing for 2 hours after mechanical stirring, and obtain mixed powder.

[0050] (3) High-temperature uniform premixing: put the mixed powder in a stainless steel crucible, put it into the tube furnace again, evacuate to 500Pa, keep the pressure for 3 hours, and then fill it with high-purity argon to 1000Pa. Afterwards, high-temperature uniform premixing is carried out, the heating rate is 15°C / min, the sintering temperature is 650°C, and the temperature is kept for 2 hours. After cooling in the furnace to below 50°C, the sintered block is taken out and put into an ultrafine pulverizer under the protection of high-purity argon. Under mechanical crushing and grinding, a part...

Embodiment 3

[0057] (1) Pretreatment: Put boron powder in acetone (B:CH 3 COCH 3 =1g:8mL) soaked for 48h, suction filtered, and vacuum-dried.

[0058] (2) Uniform premixing: Weigh the atomized magnesium powder and pretreated boron powder at a molar ratio of 1:9, add them to a three-dimensional mixer for premixing for 3 hours after mechanical stirring, and obtain mixed powder.

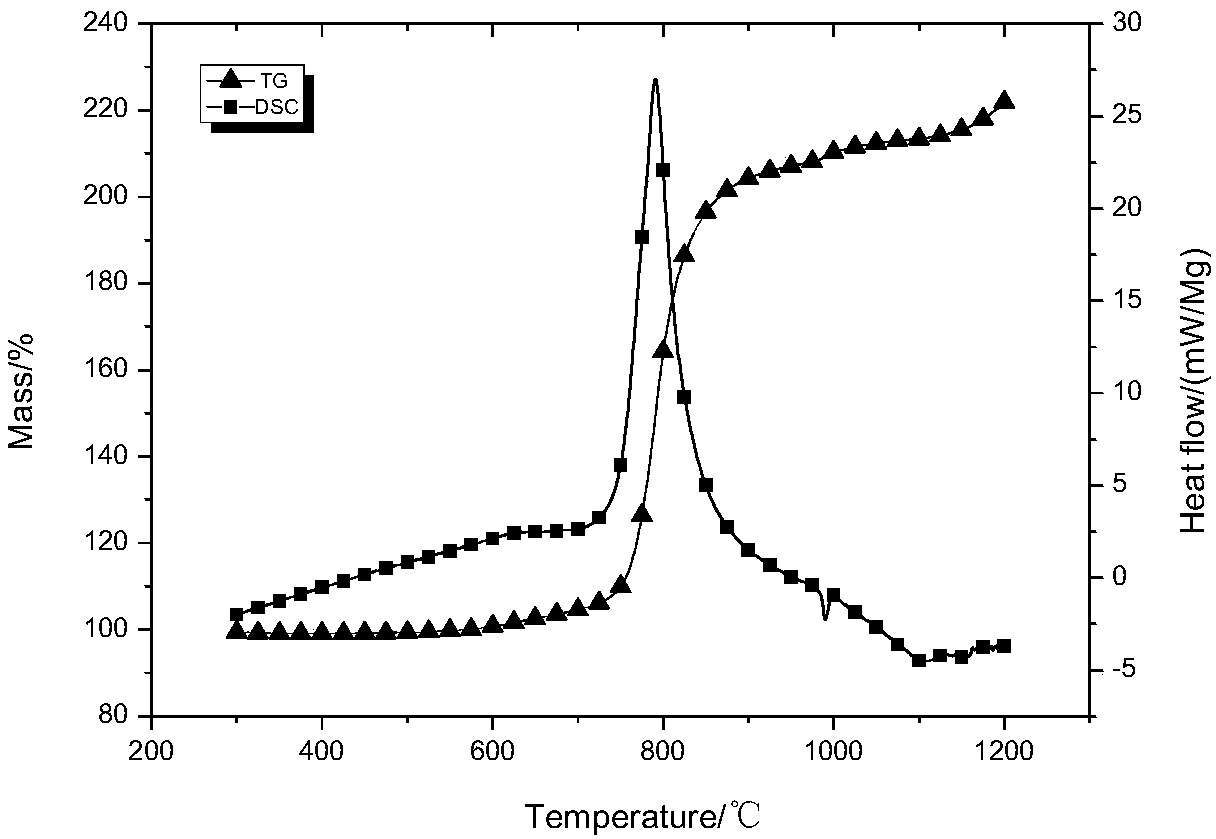

[0059] (3) High-temperature uniform premixing: put the mixed powder in a stainless steel crucible, put it into a tube furnace, evacuate to 500Pa, hold the pressure for 5h, and then fill it with high-purity argon to 500Pa. Afterwards, high-temperature uniform premixing is carried out, the heating rate is 20°C / min, the sintering temperature is 700°C, and the temperature is kept for 1 hour. After cooling to below 50°C with the furnace, the sintered block is taken out and put into an ultrafine pulverizer under the protection of high-purity argon. Under mechanical crushing and grinding, a part of pre-alloyed powder is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat release | aaaaa | aaaaa |

| Heat release | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com