Preparation method of slowly digestive starch

A technology that digests starch slowly and is applied in the field of preparation of slowly digestible starch, which can solve problems such as heavy economic burden and achieve the effects of improved crystallinity, high yield, and good health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

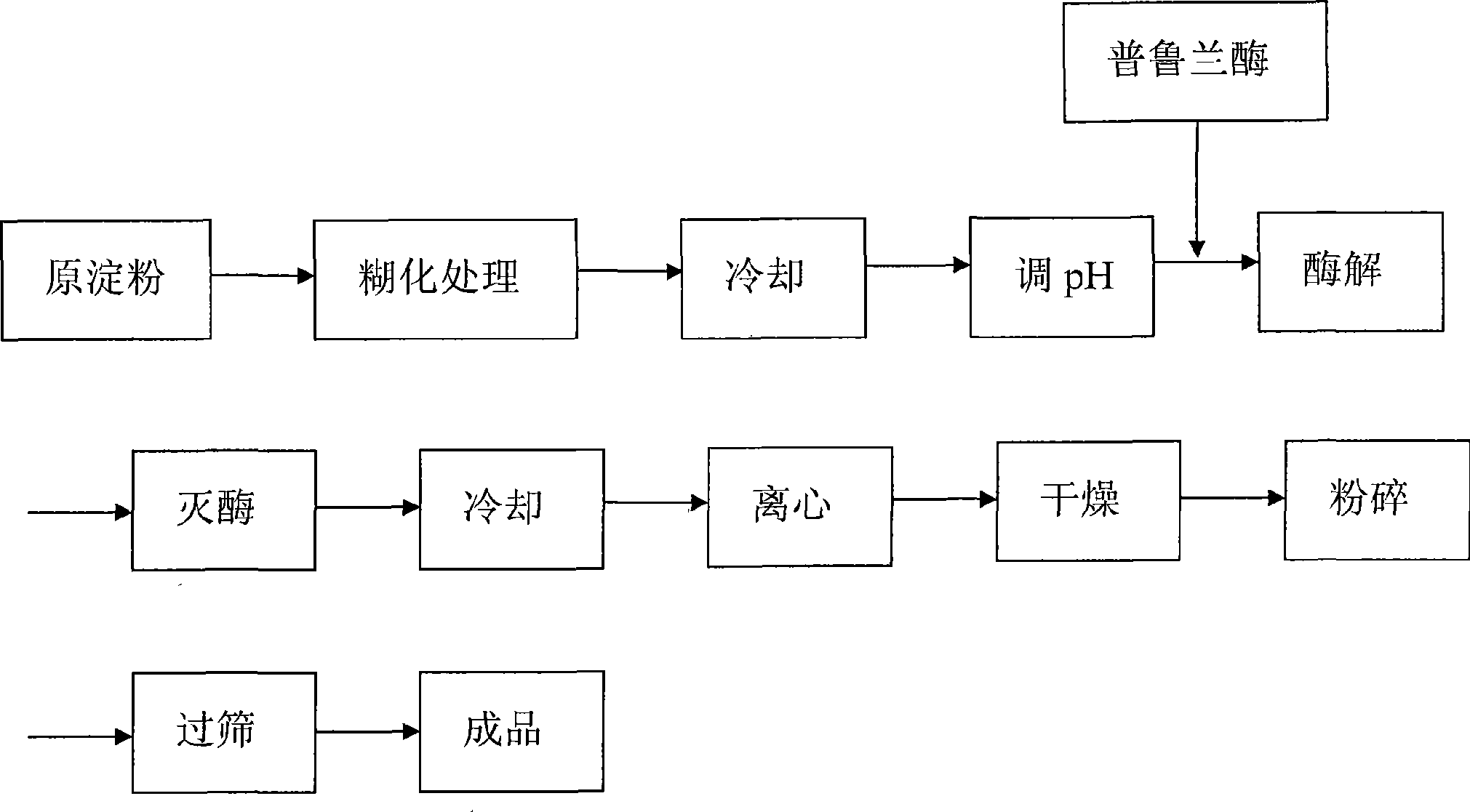

Image

Examples

Embodiment 1

[0021] Embodiment 1, the used starch raw material of the present invention except cornstarch, can adopt other starch raw materials, as raw material processing raw starch such as potato, cassava, wheat, sweet potato, mung bean, also can adopt waxy starch. The enzyme preparation adopted in the present invention is pullulanase, the enzyme debranching treatment conditions are controlled, the crystal structure of the original starch is changed, and high enzyme concentration and short debranching treatment time are used for treatment. After the enzyme treatment is completed, it is refrigerated at 1-5°C to promote the formation of a semi-crystalline structure, dried at 60°C, and crushed to an appropriate mesh size to further increase the slowly digestible starch content. The specific preparation method of slowly digestible starch of the present invention comprises:

[0022] (1) Prepare raw starch into starch milk with a mass fraction of 4-20%, heat in a boiling water bath for 30 minu...

Embodiment 2

[0031] Embodiment 2, a kind of preparation method of slowly digesting starch of the present invention, comprises the following steps:

[0032] (1) The raw material starch is formulated into starch milk with a mass fraction of 4-20%, and heated in a boiling water bath for 30 minutes to fully gelatinize the starch;

[0033] (2) Cool to 40°C, adjust the pH value of the starch paste to 4.5-5.3, add pullulanase, and oscillate in a constant temperature water bath for enzymolysis;

[0034] (3) The amount of pullulanase in the enzymolysis process is 8U / g~80U / g (enzyme unit / dry starch weight), and the enzymolysis time is 2~24h. During this process, the pH value is kept at 4.5-5.3, The treatment temperature is kept at 52-62°C;

[0035] (4) inactivate enzyme;

[0036] (5) The reaction system after inactivating the enzyme is rapidly cooled in an ice-water bath, then refrigerated at 1-5°C for 1-4 days, centrifuged, and the precipitate is taken;

[0037] (6) Dry at 60°C for 16 hours, pul...

Embodiment 3

[0038] Example 3, the cornstarch was formulated into starch milk with a mass fraction of 4%, and sealed. Heat in a boiling water bath for 30 minutes to fully gelatinize the starch, cool to about 40°C, adjust the pH value of the starch paste to 4.9, add pullulanase to 60U / g (enzyme unit / dry starch weight), mix well, and mix well at 57.5 debranching treatment in a water-bath shaker at ℃ (150r / m) for 8 hours, after enzymolysis was completed, the enzyme was inactivated in a boiling water bath for 30 minutes, cooled to 4 ℃ and stored for 2 days, then centrifuged, dried at 60 ℃ for 16 hours, crushed through a 160-mesh sieve, and slowly The digestible starch content was 31.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com