Industry method of producing fish collagen peptide from fish skin and bone by an enzyme method

A technology of fish collagen peptides and fish bones, applied in protein food processing, animal protein processing, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Embodiment 1: 1600 kilograms of frozen minced fish skins are naturally thawed at room temperature, the fish skins are cleaned with clear water, and drained. The cleaned fish bones are sent to a meat grinder for grinding, and the ground fish aggregates are transferred to an emulsification tank, and 5 to 8 times of hot alkaline water ((pH 8 to 9, 50 to 60°C) is added for emulsification treatment. Put the emulsified material into the enzymatic hydrolysis tank. Heat the material to 50°C, and adjust the pH to 8.5 with the dissolved concentrated NaOH solution. Add enzyme A at an enzyme amount of 2,000 to 10,000 units per gram of protein A. During enzymolysis, keep the temperature at 50°C and pH around 8.5, and continue enzymolysis for 3 hours. Then the material in the enzymolysis tank is cooled to about 40°C, and the pH is adjusted to about 7, according to 5000 per gram of protein Add enzyme B to control the temperature to about 60°C, and continue the enzymolysis for 2 hours. ...

Embodiment 2

[0034] Embodiment 2: 5000 kilograms of frozen fish bones are naturally thawed at room temperature, the fish bones are cleaned with clear water, drained, rinsed with warm water, and the cleaned fish skins are minced with a meat grinder. The minced fish aggregates are transferred to the emulsification tank, and 5-8 times the hot alkaline water ((pH8~9, 50~60°C)) is added for emulsification treatment. The emulsified material is put into the enzymatic hydrolysis tank. Heating makes Raise the temperature of the material to 50°C, and adjust the pH to 8.5 with the dissolved concentrated NaOH solution. Add enzyme A, and add enzyme A at an enzyme amount of 2000 to 10,000 units per gram of protein. During enzymolysis, keep the temperature at 50°C, and the pH Keep it at about 8.5, and continue enzymatic hydrolysis for 3 hours. Then cool the material in the enzymatic hydrolysis tank to about 40°C, adjust the pH to about 7, and add enzyme B at an enzyme amount of 5,000 to 10,000 units per g...

PUM

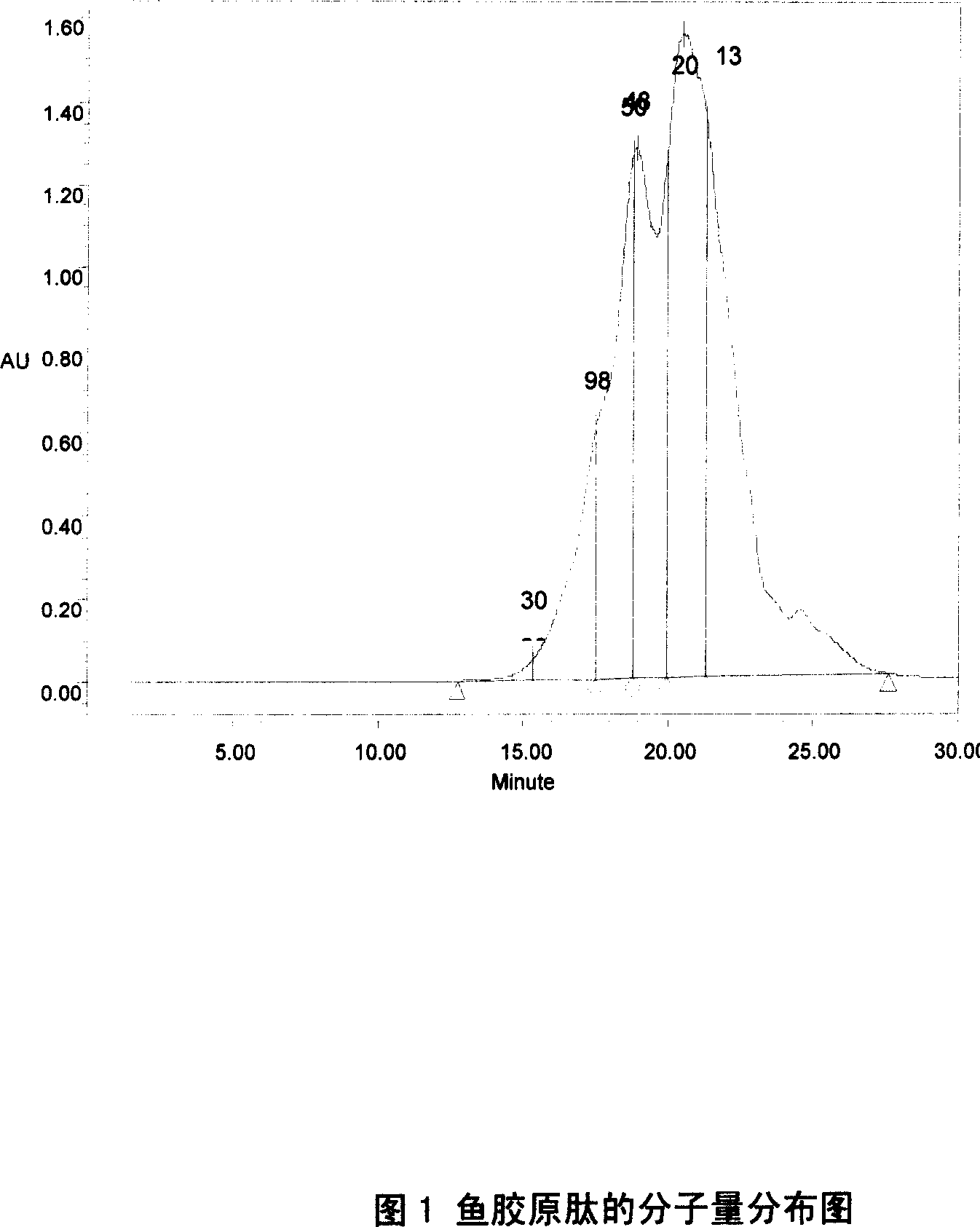

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com