Nonwoven fabric for semipermeable membrane supporting body and method for manufacturing same

A manufacturing method, semi-permeable membrane technology, applied in semi-permeable membrane separation, textiles and papermaking, chemical instruments and methods, etc., can solve the problems of many MD curls, difficult tensile strength ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

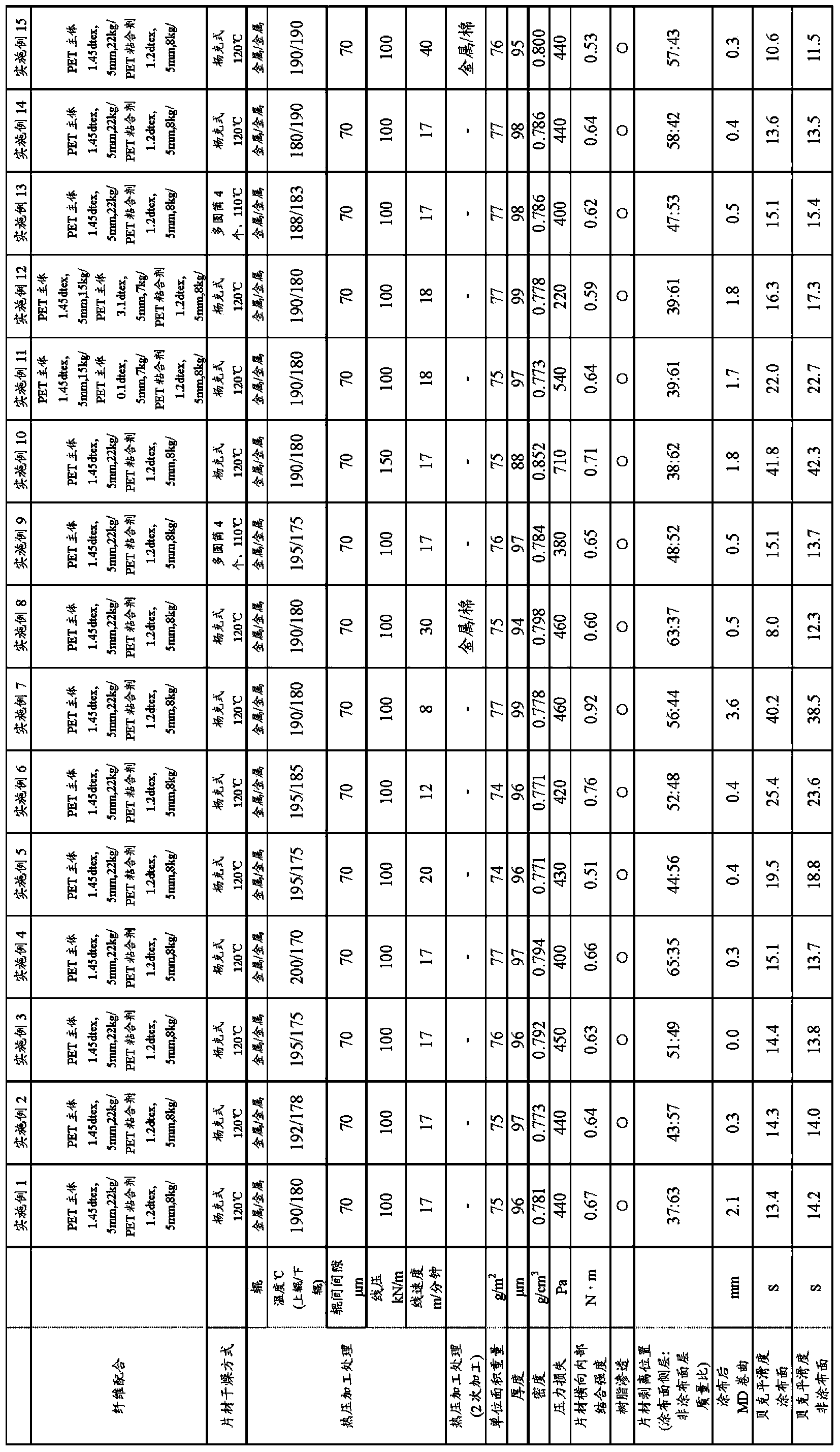

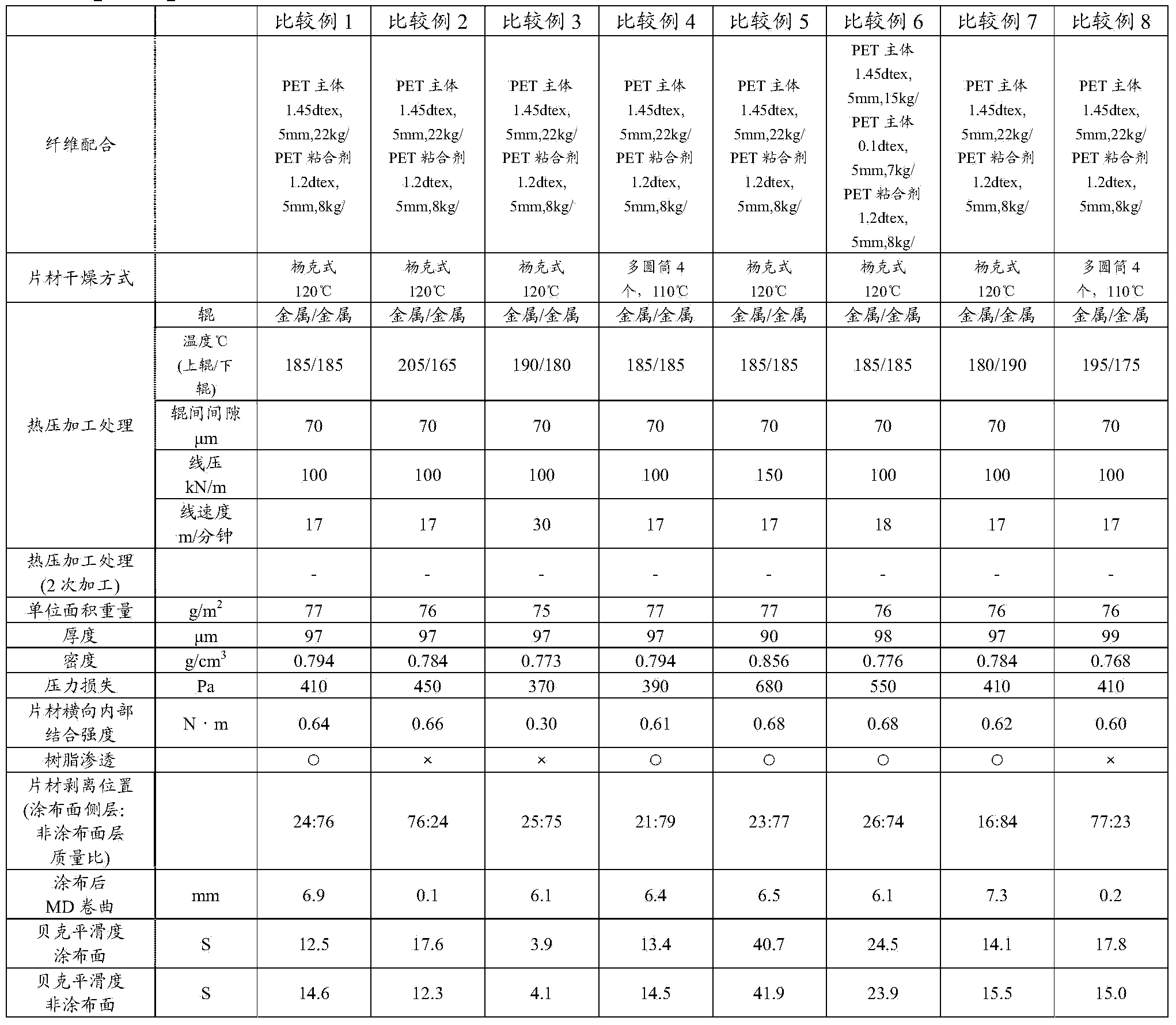

Embodiment 1

[0073]

[0074] 22 kg of commercially available polyester main fiber (trade name: EP133, manufactured by Kuraray Co., Ltd.) with a thickness of 1.45 decitex and a cut length of 5 mm and 8 kg of a thickness of 1.2 decitex and a cut length of 5 mm commercially available polyester binder fiber (trade name: TR07N, manufactured by Teijin Fibers, Ltd.) was put into water, and dispersed for 5 minutes by a disperser to obtain a fiber raw material slurry with a fiber component concentration of 1% by mass. material.

[0075]

[0076] Water was added to the fiber raw material slurry 1 to dilute the whole to obtain a fiber slurry having a fiber component concentration of 0.03% by mass.

[0077]

[0078] The fiber slurry was put into the head box (head box) of the short-wire paper machine, and after the fiber slurry was made into paper, it was dried by a Yankee dryer with a surface temperature of 120°C to obtain a continuous roll. Take the original paper.

[0079]

[0080] Metal ...

Embodiment 2

[0082]

[0083] The same operation as in Example 1 was carried out.

[0084]

[0085] The same operation as in Example 1 was carried out.

[0086]

[0087] The same operation as in Example 1 was carried out.

[0088]

[0089] In Example 1, the roll surface temperature of the upper roll / lower roll was set to 192°C / 178°C, and the base paper was subjected to hot-press processing in such a way that the Yankee dryer contact surface of the base paper was in contact with the lower roll. Otherwise, it carried out similarly to Example 1, and obtained the nonwoven fabric for semipermeable membrane support bodies.

Embodiment 3

[0091]

[0092] The same operation as in Example 1 was carried out.

[0093]

[0094] The same operation as in Example 1 was carried out.

[0095]

[0096] The same operation as in Example 1 was carried out.

[0097]

[0098] In Example 1, the roll surface temperature of the upper roll / lower roll was set to 195°C / 175°C, and the base paper was subjected to hot-press processing in such a way that the contact surface of the Yankee dryer of the base paper was in contact with the lower roll. Otherwise, it carried out similarly to Example 1, and obtained the nonwoven fabric for semipermeable membrane support bodies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com