Composite magnetic body and method for manufacturing same

A composite magnetic body and metal magnetic technology, which is applied in the manufacture of inductors/transformers/magnets, the magnetism of inorganic materials, magnetic cores/yokes, etc., can solve the problem that it is difficult to further obtain powder magnetic cores, and metal magnetic particles cannot obtain sufficient mechanical strength, etc. problems, achieve the effects of improving mechanical strength, suppressing eddy current loss, and suppressing contact frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

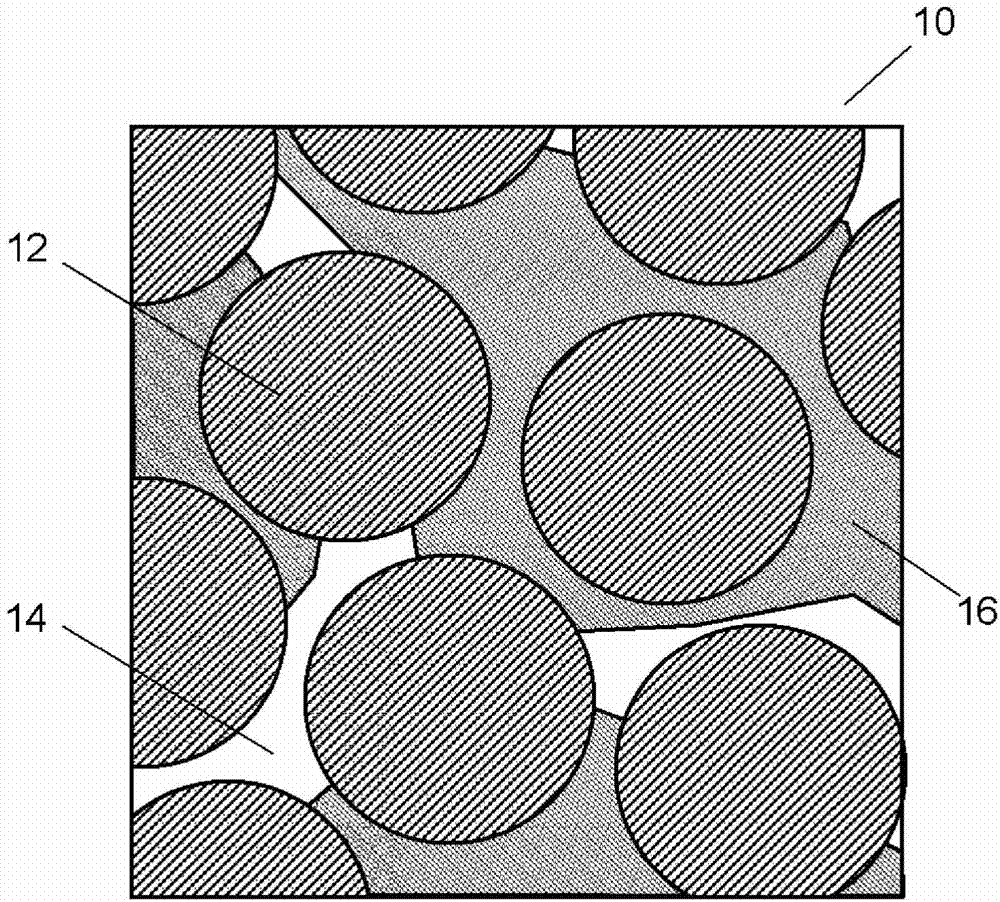

[0021] figure 1 It is an enlarged schematic cross-sectional view of the composite magnetic body 10 in Embodiment 1 of the present invention. Composite magnetic body 10 includes metal magnetic powder composed of a plurality of metal magnetic particles 12 , and insulating resin 16 as an insulator impregnated at least part of gaps 14 between the plurality of metal magnetic particles 12 .

[0022] The metal magnetic powder used in the composite magnetic body 10 is not particularly limited, but from the viewpoint of suppressing magnetic saturation at a large current, a material with a high saturation magnetization and mainly composed of iron is suitable. As examples of the material of the metal magnetic powder, in addition to iron, Ni, Si, Al, etc. are added to improve the soft magnetic properties, Fe-Ni alloy, Fe-Si alloy, Fe-Al-Si alloy, various non- Crystal alloys, metallic glass alloys, etc.

[0023] The method for producing the metal magnetic powder is not particularly limit...

Embodiment 1

[0054] In Sample No. 1 to Sample No. 41 shown in (Table 1), Fe—Si alloy powder having an average particle diameter of 20 μm produced by a gas atomization method was used as the metal magnetic powder. 0.2 wt% of a titanium coupling agent was added to the metal magnetic powder as an insulating material. Furthermore, the 1st polymer and the 2nd polymer were added in the ratio shown in (Table 1). As the first polymer, a first phenol resin having three or more side chains consisting of 8 carbon atoms and not having side chains consisting of 12 or more carbon atoms or silicon atoms is used. As the second polymer, a second phenol resin that does not have a side chain (the side chain is 0) composed of 7 or more carbon atoms or silicon atoms is used. In addition, in the present embodiment, the term "phenol resin" means that the main chain in the framework of the resin is unique to the phenol resin, and the side chain is not particularly limited.

[0055] For any sample, a small amoun...

Embodiment 2

[0079] In Sample No. 42 to Sample No. 45 shown in (Table 2), Fe—Si—Cr—B—C amorphous alloy powder having an average particle diameter of 30 μm produced by a water atomization method was used as the metal magnetic powder. To this metal magnetic powder, 0.5 wt % of alumina powder having an average particle diameter of 1 μm was added as an insulating material. Furthermore, the first polymer and the second polymer were mixed together with a small amount of toluene at 0.8% by weight relative to the metal magnetic powder. As the first polymer, a first epoxy resin having three or more side chains of 10 carbon atoms and no side chains of 12 or more carbon atoms is used. As the second polymer, a second epoxy resin having a total of three or more side chains consisting of 10 carbon atoms and side chains consisting of 13 carbon atoms is used.

[0080] The obtained mixture was dried at 90° C. for 30 minutes, and the dried product was pulverized and classified into a particle diameter of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com