Direct yarn impregnating compound for insulator as well as preparation method and application thereof

A technology of sizing agent and insulator, which is applied in the direction of textiles, papermaking, fiber treatment, etc., can solve the problems of glass fiber reinforced epoxy resin pipe deterioration, etc., and achieve good compatibility and interface bonding, good compatibility, and good mechanical properties The effect of performance and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

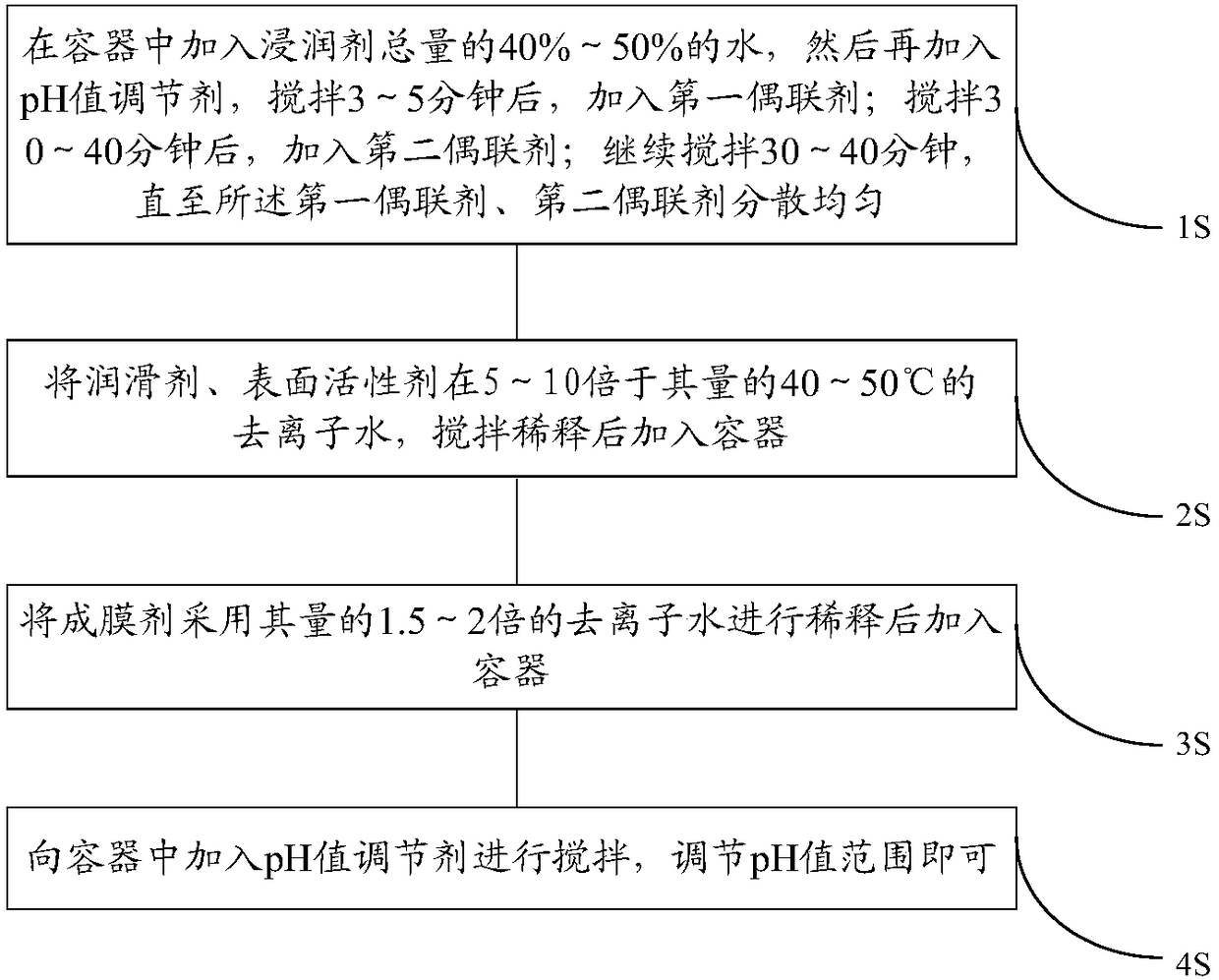

[0056] The preparation method of the direct yarn sizing agent for insulators comprises the following steps:

[0057] 1S: Add 40% to 50% of the total amount of water in the container, and then add the pH adjuster. After stirring for 3 to 5 minutes, add the first coupling agent; after stirring for 30 to 40 minutes, add the second coupling agent. Second coupling agent; continue to stir for 30-40 minutes until the first coupling agent and the second coupling agent are dispersed evenly;

[0058] 2S: Dissolve lubricant, antistatic agent and surfactant in 5 to 10 times the amount of water at 40 to 50°C, stir and dilute, then add to the container;

[0059] 3S: Dilute the film-forming agent with 1.5 to 2 times the amount of water and add it to the container;

[0060] 4S: Add the pH adjuster to the container again and stir to adjust the pH range.

Embodiment

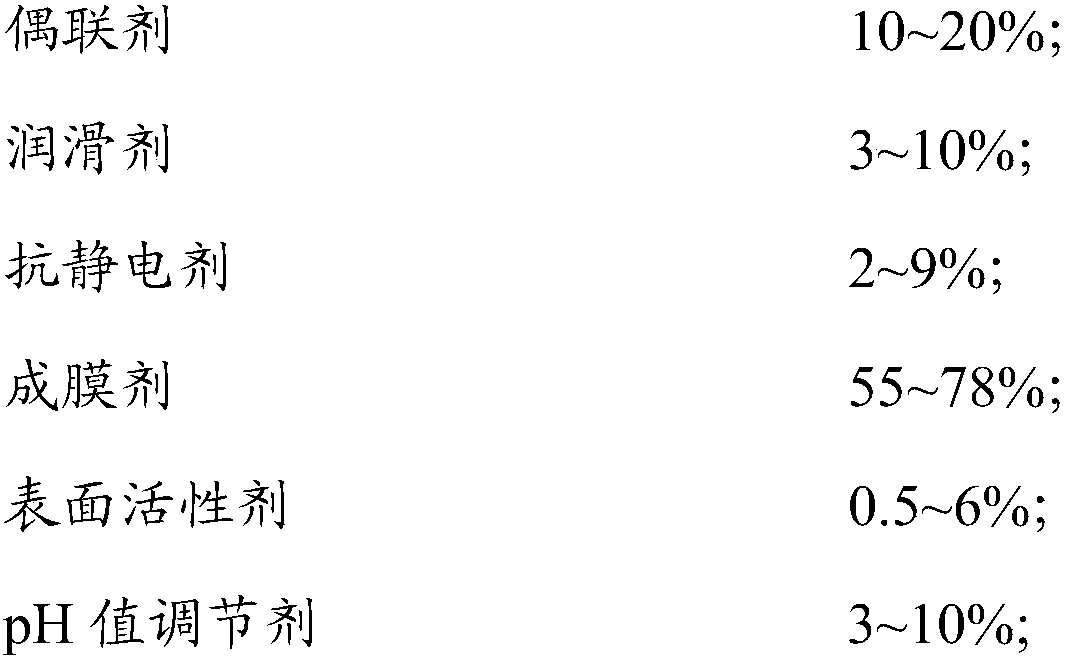

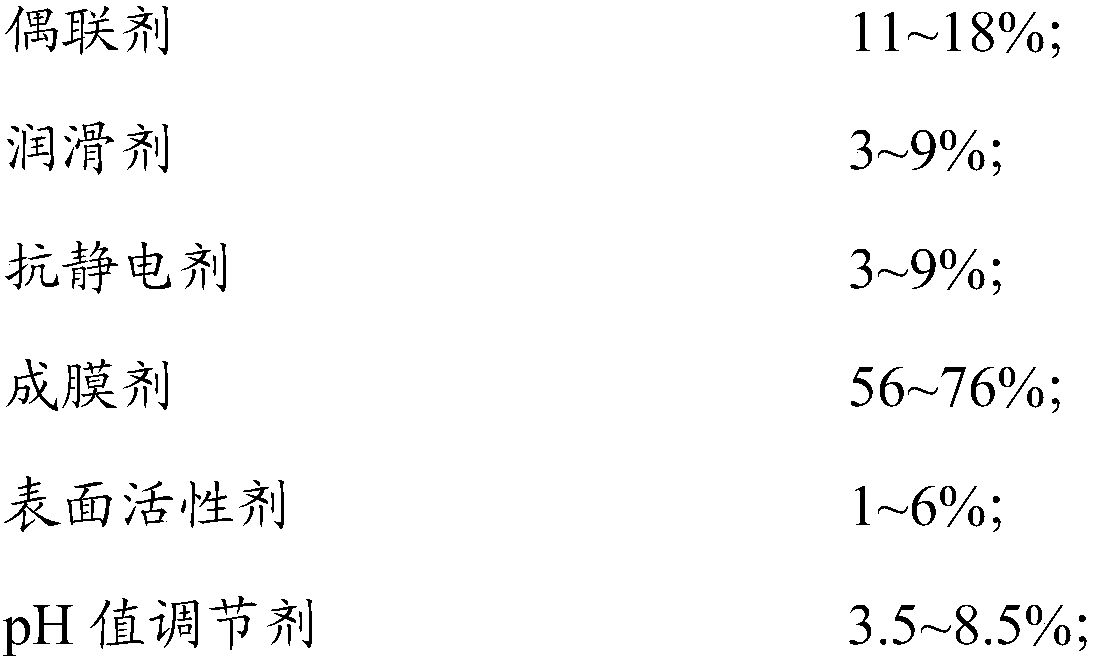

[0062] The components of the wetting agent used in the embodiments of the present invention are as follows:

[0063] Coupling agent: 3-glycidyl etheroxypropyl trimethoxysilane coupling agent, the product brand is A-187; γ-aminopropyl trimethoxysilane, the product brand is A-1100;

[0064] The lubricant uses PEGMO;

[0065] The antistatic agent uses polyoxyethylene fatty quaternary ammonium salt;

[0066] Film-forming agent: bisphenol A type epoxy resin emulsion, product brand is Neoxil 965 (manufacturer: Netherlands DSM company); bisphenol F type epoxy resin emulsion, product brand is Neoxil 962 / D (manufacturer: Netherlands DSM company) );

[0067] The non-ionic surfactant adopts alkylphenol polyoxyethylene ether OP;

[0068] The pH regulator uses acetic acid.

[0069] Example

[0070] Table 1 shows some examples of the direct yarn sizing agent for insulators according to the present invention.

[0071] Table 1 list of specific examples of wetting agent

[0072]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com