Easy-to-brew granulated green tea processing technology

A processing technology and granule technology, which is applied in the field of granule green tea processing technology that is easy to brew, can solve the problems that the leaching rate and slag output of granule green tea processing cannot be balanced, and achieve the advantages of easy brewing, high tea quality, and increased contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] When puffing, put the granular green tea in the puffing machine, control the temperature at 50°C, the pressure at 0.2MPa, and keep it for 5min; Lower the temperature to -10°C and hold for 5 minutes.

Embodiment 2

[0028] When puffing, put the granular green tea in the puffing machine, control the temperature at 65°C, the pressure at 0.3MPa, and keep it for 15min; Lower the temperature to -3°C and keep for 15 minutes.

Embodiment 3

[0030] When puffing, put the granular green tea in the puffing machine, control the temperature at 80°C, the pressure at 0.4MPa, and keep it for 25min; Lower the temperature to 4°C and hold for 25 minutes.

[0031] The patent name is: a method for processing granular green tea, and the patent application number is: 201010039564.8 The processing method provided by the invention patent is a comparative example.

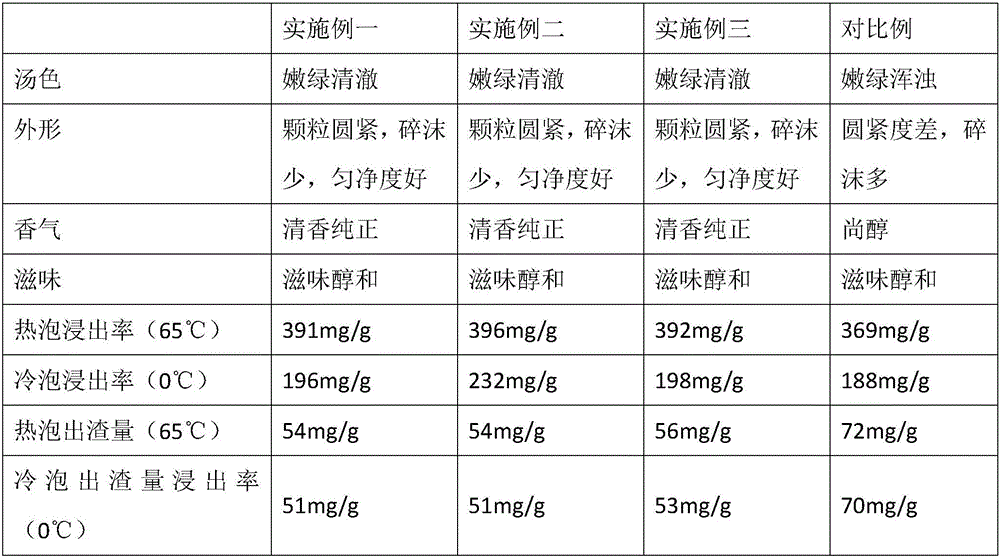

[0032] After brewing the granular green tea obtained in Examples 1 to 3 and Comparative Example respectively under the same environment with the same weight, the results in Table 1 are obtained after testing:

[0033] Table 1

[0034]

[0035] As can be seen from the above table, compared with the granular green tea obtained by using the processing method of the comparative patent, the granular green tea produced by the present invention has a round and tight shape, less broken foam, and better uniformity. And the brewed soup is green and clear, with pure aroma and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com