Glass fiber stranded twistless rough yarn impregnating compound, and preparation method, product and application thereof

A technology of roving and glass fiber, which is applied in the field of sizing agent and preparation of glass fiber plied roving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the glass fiber plied roving sizing agent comprises the following steps:

[0056] 1S: Add 40% to 50% of the total amount of water in the container, and then add the pH adjuster. After stirring for 3 to 5 minutes, slowly add the first coupling agent. After stirring for 20 to 30 minutes, slowly Add the second coupling agent and continue stirring for 20-30 minutes until the first coupling agent and the second coupling agent are uniformly dispersed; wherein, slowly adding the coupling agent helps the coupling agent to be uniformly dispersed, while preventing the When the coupling agent is added quickly, splashing occurs, generally at a rate of 100-200 g / s;

[0057] 2S: Dissolve the lubricant in 5 to 10 times its amount of water at 40 to 50°C, stir and dilute it, and add it to the container; dissolve the antistatic agent in 5 to 10 times its amount of water at 80 to 90°C, stir Add to the container after dilution;

[0058] 3S: Dilute the first film...

Embodiment

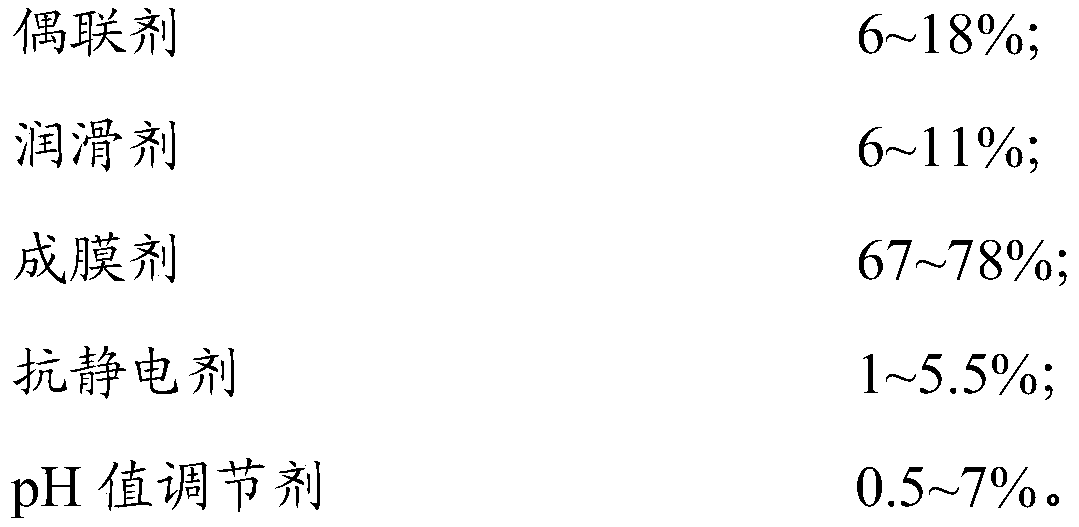

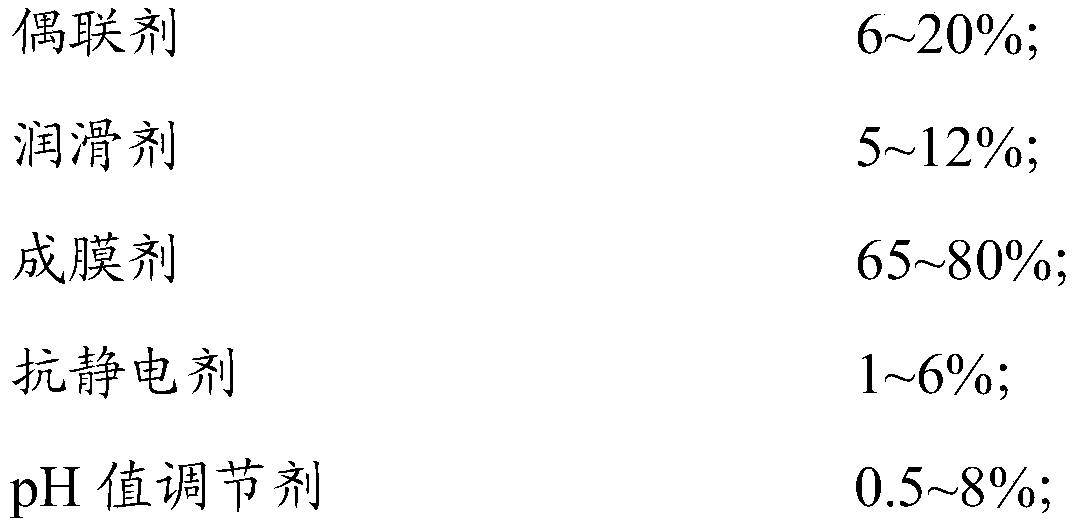

[0062] Each component of the wetting agent used in the embodiment of the present invention is as follows:

[0063] Coupling agent:

[0064] Methyl propyl acyloxy trimethoxy silane coupling agent, product name is A-174; or

[0065] Vinyl tris (β-methoxyethoxy) silane, product name is A-172;

[0066] γ-aminopropyltrimethoxysilane coupling agent, the product brand is A-1100;

[0067] Lubricant: PEG400;

[0068] Film former:

[0069] The epoxy-modified polyester resin emulsion can be prepared according to the existing literature or commercial products can be used. (using the solvent method, put the monobasic acid, E-44 epoxy resin, IPA, TMP, pentaerythritol, organotin catalyst, and xylene into the four-necked flask by metering, and gradually heat up to 220°C in 1h, and react to an acid value of 60~ 80mg KOH / g; cool down to 170°C, add DMPA, react at 170°C to an end-point acid value of 21-30mg KOH / g, vacuum to remove the xylene solvent in the system, and obtain an epoxy-modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com