Laminating adhesive, laminate including the same, and method of making a laminate

A technology of adhesives and laminates, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesives, etc., can solve the problem of not always being able to prepare adhesives and/or laminates, reduce specific Film heat sealing performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0096] Another suitable method of preparing a laminate comprises applying an adhesive composition to a first substrate, contacting the coated adhesive composition with a second substrate, and combining the adhesive The object or the component as a whole is exposed to radiation. The adhesive composition may be exposed to radiation before, during, or after contacting the adhesive composition with the second substrate.

[0097] Useful substrates include flexible films including, for example, metal foils (aluminum foils), polymer films, and metallized polymer films including, for example, polyolefins (e.g., polypropylene, polyethylene, low density polyethylene, Linear low-density polyethylene, high-density polyethylene, polypropylene, and oriented polypropylene; copolymers of polyolefins with other comonomers), metallized polyolefins (e.g., metallized polypropylene), metallized polyether paraphenylene Dicarboxylates, ethylene vinyl acetate, ethylene methacrylic acid ionomers, eth...

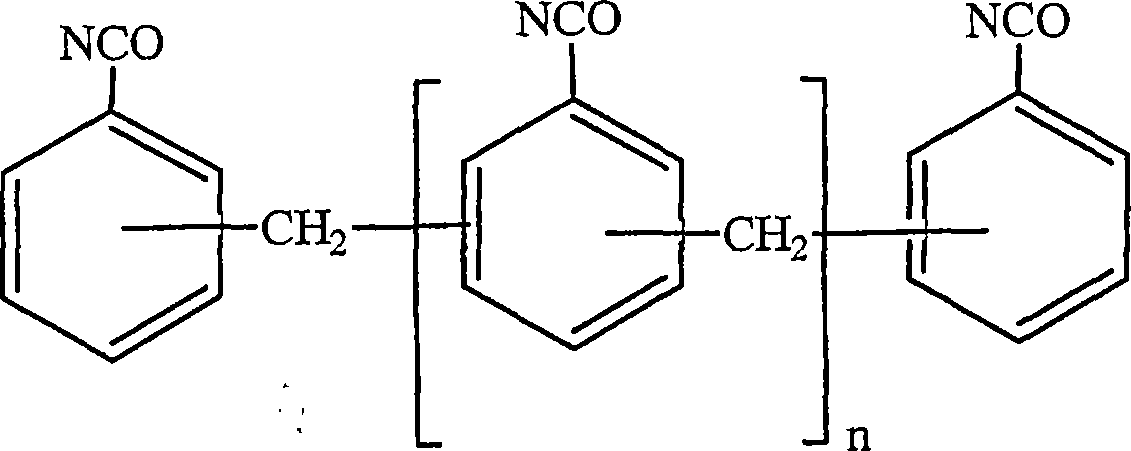

Embodiment 1-8

[0115] Part A was prepared by adding DESMOPHEN S-1011-210 polyester polyol (Bayer Corporation, Pittsburg, Pennsylvania) to a reactor and heating to 130°F. Turn on and maintain nitrogen protection during operation. A sufficient amount of LUPRANATE MI monomer 2,4'-diphenylmethane diisocyanate (MDI) (BASF Corporation, Syandotte, Michigan) was then added to the reactor to achieve a stoichiometric ratio NCO / OH of 2 / 1 (NCO / OH OH) to 2.5 / 1 (NCO / OH). Stir the mixture and allow the temperature to rise to 160°F to 170°F. The reaction is complete within 1 to 2 hours. The %NCO is checked periodically to determine if the reaction is complete, ie: if the target %NCO is reached. Stirring was then stopped and 2-hydroxyethyl acrylate (HEA) (Dow Chemical Co., Midland, Michigan) was added to the reactor for reaction while maintaining a temperature of 160°F to 170°F. The second step reaction is completed within 1 to 2 hours. Check the %NCO to determine if the reaction is complete. Stirring ...

Embodiment 9

[0128] Part A was prepared as follows. 41.5 g of polyester polyol RUCOFLEX 1011-210 was charged to the reactor and heated to 130°F. Turn on and maintain nitrogen protection during operation. A 41.5 g amount of LUPRANATE MI monomer 2,4'-diphenylmethane diisocyanate (MDI) (BASF Corporation, Syandotte, Michigan) was then added to the reactor. Stir the mixture and allow the temperature to rise to 160°F to 170°F. The reaction is complete within 1 to 2 hours. Periodically check the %NCO to determine if the reaction is complete. Stirring was then stopped and the temperature was reduced to 140°F, 8g of 2-hydroxyethyl acrylate (HEA) (Dow Chemical Company, Midland, Michigan) was added to the reactor and the reaction was carried out at a temperature of 160°F to 170°F . The second step reaction is completed within 1 to 2 hours. Check the %NCO to determine if the reaction is complete. Stirring was then stopped and 9 g of LUPRANATE MI monomeric MDI was added to the reactor. Stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com