Heat-resistant low-pressure-change rubber and preparation method thereof

A low-pressure change and rubber technology, which is applied in the field of heat-resistant low-pressure rubber, can solve the problems that rubber is easy to soften and deform, and cannot be used normally, and achieves the effects of improving wear resistance, heat resistance, and compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

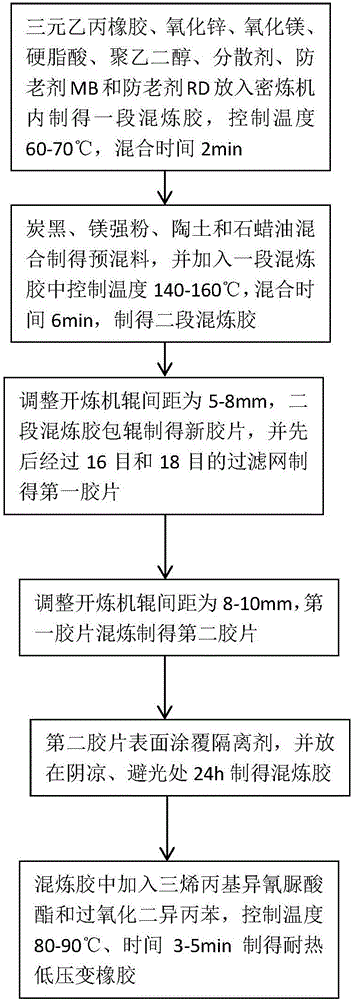

[0043] A method for preparing heat-resistant low-pressure deformation rubber, comprising the following steps:

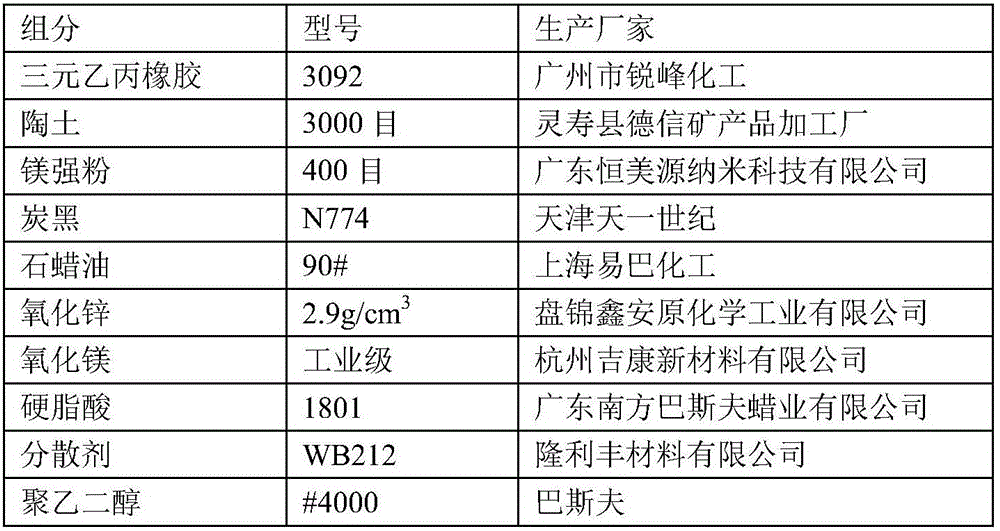

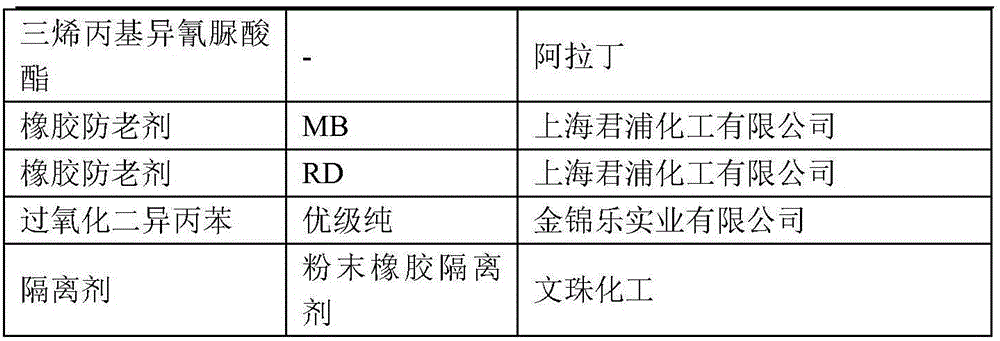

[0044] Step 1: Put 100kg EPDM rubber, 6kg zinc oxide, 12kg magnesium oxide, 2kg stearic acid, 3kg polyethylene glycol, 3kg dispersant, 2kg antiaging agent MB and 2kg antiaging agent RD into the internal mixer for reaction A section of mixed rubber was prepared in 2 minutes, and the reaction temperature was 65°C;

[0045]Step 2: Mix 40kg carbon black, 60kg magnesium powder, 60kg clay and 25kg paraffin oil and stir for 5 minutes to make a premix; pour the premix into the internal mixer in step 1 and continue mixing for 6 minutes to make the second stage Mixed rubber, the reaction temperature is 150°C;

[0046] Step 3: Adjust the roller spacing of the open mill to 6mm, put the second-stage mixed rubber in step 2 on the open mill to cover the rolls, and obtain a new film with a width of 100mm, which is filtered through a filter machine to obtain the first One film, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com