Antibacterial and mildewproof latex foam material and preparation method thereof

A foam material, antibacterial and anti-mildew technology, which is applied in the field of chemical materials and polymer materials, can solve problems such as difficult to obtain satisfactory anti-mildew effect, and achieve excellent anti-bacterial and anti-mildew properties, increased strength, and fine cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

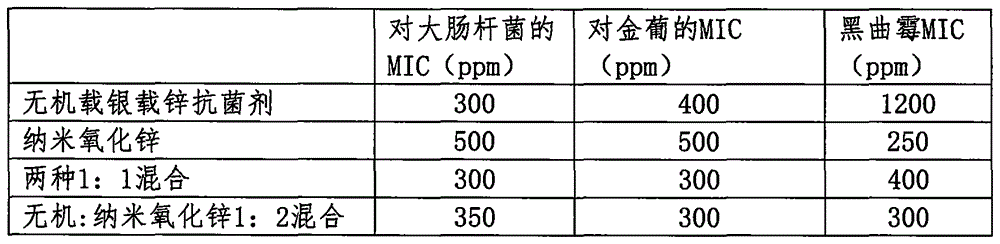

Problems solved by technology

Method used

Image

Examples

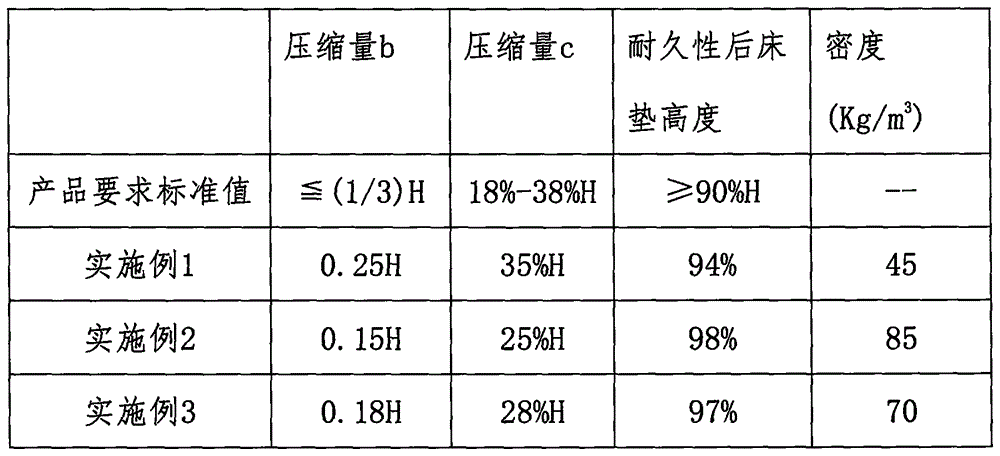

Embodiment 1

[0062] Latex composition: 100% natural latex, which is formulated into latex with a concentration of 65%.

[0063] Accurately weigh the following materials: 65% latex 200Kg, 25% potassium hydroxide solution 3Kg, vegetable potassium oleate 2.6Kg, castor oil potassium 1.5Kg, sulfur 5.2Kg, antioxidant 264 1.5Kg, sodium silicofluoride 2.6 Kg, bentonite 1.5Kg, nano-zinc oxide 5.2Kg, inorganic silver-zinc composite antibacterial agent 0.65Kg.

[0064] Add natural latex into the container, and remove ammonia by suction for 6-10 hours under constant stirring. Then add 0.65Kg of inorganic silver-based antibacterial agent and 1.5Kg of anti-aging agent 264, and stir for 30 minutes until the product is evenly dispersed. Then add potassium hydroxide of 3Kg 25% concentration, potassium vegetable oleate of 2.6Kg, potassium castor oil of 1.5Kg, sulfur of 5.2Kg, nano zinc oxide of 5.2Kg, sodium silicofluoride of 1.3Kg, soap of 1.2Kg Soil, stirring continuously for 2-4 hours, let it mature an...

Embodiment 2

[0066] Latex composition: natural latex, 30wt%; synthetic latex, 70wt%; it is formulated into the latex of 65% concentration.

[0067] Accurately weigh the following materials: 65% latex 200Kg, 25% potassium hydroxide solution 3Kg, vegetable potassium oleate 5.2Kg, castor oil potassium 2.6Kg, sulfur 7.8Kg, antioxidant 264 2Kg, sodium silicofluoride 1.3Kg , bentonite 1.2Kg, nano-zinc oxide 7.8Kg, inorganic silver-zinc composite antibacterial agent 1Kg.

[0068] Add natural latex into the container, and remove ammonia by suction for 6-10 hours under constant stirring. Then add inorganic silver-based antibacterial agent and anti-aging agent 264, and stir for 30 minutes until the product is evenly dispersed. Then add potassium hydroxide, potassium vegetable oleate, potassium castor oil, sulfur, nano-zinc oxide, sodium silicofluoride, and bentonite, and keep stirring for 2-4 hours to allow it to mature and foam gradually. Preheat the mold to 30 degrees in advance, apply silicone ...

Embodiment 3

[0070] Latex composition: 100% by weight of synthetic latex; it is formulated into latex with a concentration of 65%.

[0071] Accurately weigh the following materials: 65% latex 200Kg, 25% potassium hydroxide solution 3Kg, vegetable potassium oleate 6.5Kg, castor oil potassium 2Kg, sulfur 5.2Kg, antioxidant 264 2.6Kg, sodium silicofluoride 1.9Kg , bentonite 1.9Kg, nano-zinc oxide 6.5Kg, inorganic silver-zinc composite antibacterial agent 1.3Kg.

[0072] Add inorganic silver-based antibacterial agent and anti-aging agent 264 into the latex, and stir for 30 minutes until the product is evenly dispersed. Then add potassium hydroxide, potassium vegetable oleate, potassium castor oil, sulfur, nano-zinc oxide, sodium silicofluoride, and bentonite, and keep stirring for 2-4 hours to allow it to mature and foam gradually. Preheat the mold to 30 degrees in advance, apply silicone oil or zinc stearate on the template, then inject the material foam into the mold or conveyor belt, set t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com