Low-temperature-resistant and abrasion-resistant cable

A low temperature resistant, cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of shortened cable life, non-wear resistance, easy cracking, etc., to improve compatibility, increase wear resistance, and small permanent deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

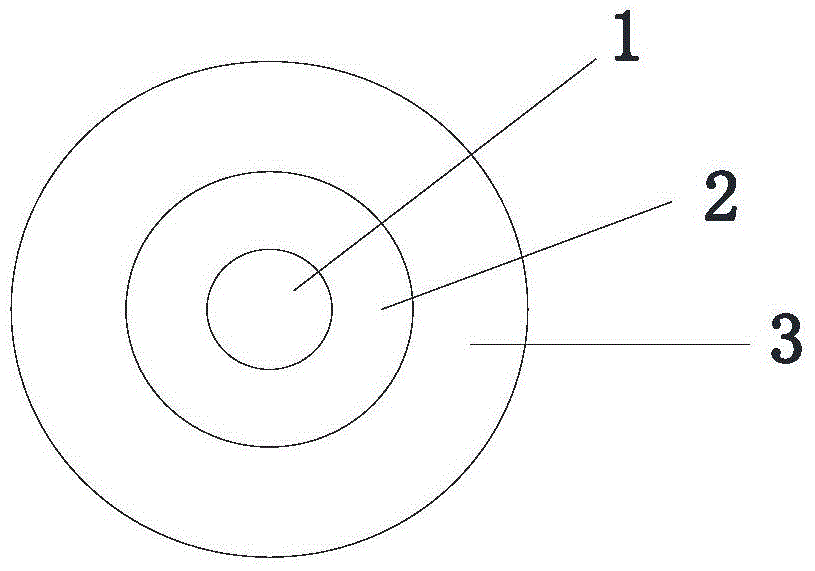

[0026] A low-temperature and wear-resistant cable, comprising: a conductive cable core 1, an inner protective sheath 2 and an outer protective sheath 3, the inner protective sheath 2 covers the conductive cable core 1, and the outer protective sheath 3 covers the inner protective sheath 2;

[0027] Among them, the raw materials of the outer protective cover include by weight: 50 parts of methyl vinyl phenyl silicone rubber with a phenyl content of 5 wt%, 15 parts of hydrogenated nitrile rubber, 15 parts of solution polystyrene butadiene rubber, and 6 parts of methyl fluorosilicone oil. 20 parts of epoxy soybean oil, 20 parts of dioctyl nylon acid, 20 parts of fumed silica, 8 parts of microencapsulated red phosphorus, 25 parts of melamine phosphate, 0.5 parts of dicumyl peroxide, vinyl tri 0.3 parts of ethoxysilane, 0.3 parts of zinc oxide, 3 parts of Ca / Zn composite stabilizer, 1 part of TX-1 type rare earth stabilizer, 1 part of magnesium stearate, 10760.1 parts of antioxidant...

Embodiment 2

[0030] A low-temperature and wear-resistant cable, comprising: a conductive cable core 1, an inner protective sheath 2 and an outer protective sheath 3, the inner protective sheath 2 covers the conductive cable core 1, and the outer protective sheath 3 covers the inner protective sheath 2;

[0031] Among them, the raw materials of the outer protective cover include by weight: 70 parts of methyl vinyl phenyl silicone rubber with a phenyl content of 15 wt%, 25 parts of hydrogenated nitrile rubber, 25 parts of solution polystyrene butadiene rubber, and 10 parts of methyl fluorosilicone oil. 30 parts of epoxy soybean oil, 30 parts of dioctyl nylon acid, 40 parts of fumed silica, 12 parts of microencapsulated red phosphorus, 35 parts of melamine phosphate, 1 part of dicumyl peroxide, vinyl three 0.7 parts of ethoxysilane, 0.7 parts of zinc oxide, 4 parts of Ca / Zn composite stabilizer, 3 parts of TX-1 type rare earth stabilizer, 2 parts of magnesium stearate, 10760.3 parts of antioxi...

Embodiment 3

[0034] A low-temperature and wear-resistant cable, comprising: a conductive cable core 1, an inner protective sheath 2 and an outer protective sheath 3, the inner protective sheath 2 covers the conductive cable core 1, and the outer protective sheath 3 covers the inner protective sheath 2;

[0035] Among them, the raw materials of the outer protective cover include by weight: 55 parts of methyl vinyl phenyl silicone rubber with a phenyl content of 8 wt%, 22 parts of hydrogenated nitrile rubber, 18 parts of solution-polymerized styrene-butadiene rubber, and 9 parts of methyl fluorosilicone oil. 22 parts of epoxy soybean oil, 28 parts of dioctyl nylon acid, 25 parts of fumed silica, 11 parts of microencapsulated red phosphorus, 27 parts of melamine phosphate, 0.9 parts of dicumyl peroxide, vinyl tri 0.4 parts of ethoxysilane, 0.6 parts of zinc oxide, 3.2 parts of Ca / Zn composite stabilizer, 2.5 parts of TX-1 type rare earth stabilizer, 1.3 parts of magnesium stearate, 10760.25 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com