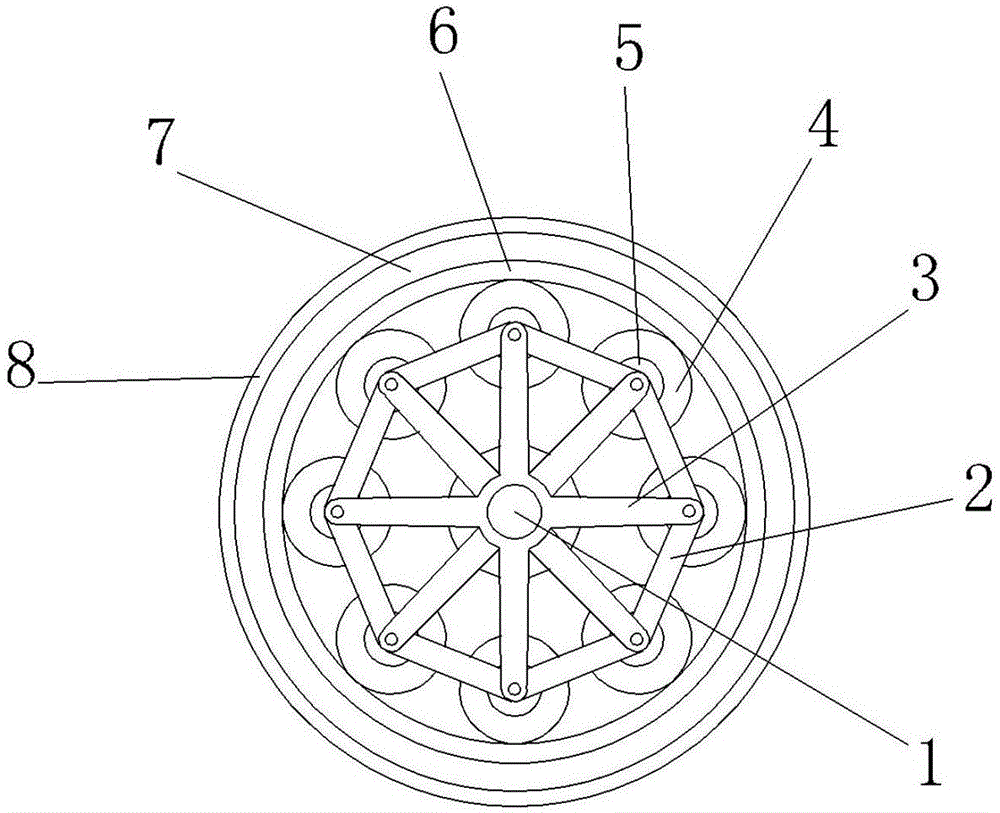

Mining anti-extrusion high-wear-resistance cable

A technology with high wear resistance and extrusion resistance, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem that the extrusion resistance and abrasion resistance cannot meet the performance requirements of mine cables, cable wear resistance, external resistance High tensile performance requirements, dangerous areas of gas accumulation, etc., to achieve the effect of improving vulcanization efficiency, improving anti-aging performance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The raw materials of the sheath layer 7 include by weight: 90 parts of nitrile rubber, 45 parts of neoprene rubber, 40 parts of EPDM rubber, 35 parts of chlorinated polyethylene, 19 parts of maleic anhydride grafted EVA, and 7.5 parts of zinc oxide , 3 parts of chlorinated paraffin, 5.5 parts of calcium stearate, 7.5 parts of white carbon black, 10 parts of talcum powder, 9 parts of activated kaolin, 5 parts of antimony trioxide, 4.5 parts of triphenyl phosphite, 4 parts of magnesium hydroxide , 4.5 parts of alumina, 5.5 parts of anti-aging agent RD, 3.5 parts of N, N'-di-sec-butyl-p-phenylenediamine antioxidant, 4 parts of vulcanizing agent DTDM, and 5.5 parts of vulcanizing agent PDM;

[0032] Wherein, N, N '-di-sec-butyl-p-phenylenediamine antioxidant is prepared according to the following process:

[0033] S1. Mix copper nitrate, chromium nitrate and barium nitrate in a mass ratio of 10:1:1, heat at 400° C. for 2 hours, and then wash and activate to obtain catalyst ...

Embodiment 2

[0036] The raw materials of the sheath layer 7 include by weight: 60 parts of nitrile rubber, 60 parts of neoprene rubber, 20 parts of EPDM rubber, 50 parts of chlorinated polyethylene, 12 parts of maleic anhydride grafted EVA, and 12 parts of zinc oxide , 1 part of chlorinated paraffin, 8 parts of calcium stearate, 3 parts of white carbon black, 15 parts of talcum powder, 3 parts of activated kaolin, 9 parts of antimony trioxide, 1 part of triphenyl phosphite, 6 parts of magnesium hydroxide , 3 parts of alumina, 8 parts of antioxidant RD, 1 part of N, N'-di-sec-butyl-p-phenylenediamine antioxidant, 6 parts of vulcanizing agent DTDM, and 3 parts of vulcanizing agent PDM;

[0037] Wherein, N, N '-di-sec-butyl-p-phenylenediamine antioxidant is prepared according to the following process:

[0038] S1. Mix copper nitrate, chromium nitrate and barium nitrate in a mass ratio of 8:12:0.8, keep the temperature at 420° C. for 1 hour, and then activate catalyst a by washing with water; ...

Embodiment 3

[0041] The raw materials of the sheath layer 7 include by weight: 120 parts of nitrile rubber, 30 parts of neoprene rubber, 60 parts of EPDM rubber, 20 parts of chlorinated polyethylene, 26 parts of maleic anhydride grafted EVA, and 3 parts of zinc oxide , 5 parts of chlorinated paraffin, 3 parts of calcium stearate, 12 parts of white carbon black, 5 parts of talcum powder, 15 parts of activated kaolin, 1 part of antimony trioxide, 8 parts of triphenyl phosphite, 2 parts of magnesium hydroxide , 6 parts of alumina, 3 parts of antioxidant RD, 6 parts of N, N'-di-sec-butyl-p-phenylenediamine antioxidant, 2 parts of vulcanizing agent DTDM, and 8 parts of vulcanizing agent PDM;

[0042] Wherein, N, N '-di-sec-butyl-p-phenylenediamine antioxidant is prepared according to the following process:

[0043] S1. Mix copper nitrate, chromium nitrate and barium nitrate in a mass ratio of 12:8:1.2, keep warm at 380° C. for 3 hours, and then wash and activate to prepare catalyst a;

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com