Fluorine-containing elastomer with excellent low temperature and liquid resistance and preparation method thereof

An elastomer and low-temperature-resistant technology, which is applied in the field of fluoroelastomers and its preparation, can solve the problems of complex production process, poor low-temperature performance, and poor liquid resistance, and achieve simple preparation methods, low-cost preparation methods, and good superior performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

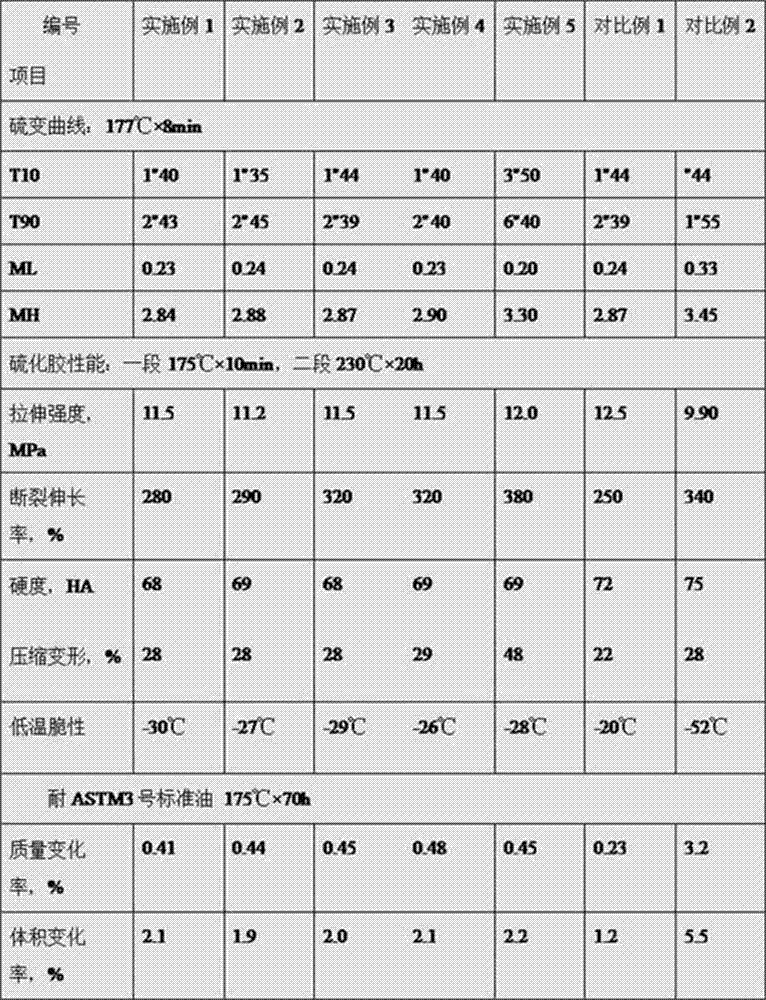

Examples

Embodiment 1

[0045] A fluoroelastomer with excellent low temperature resistance and liquid resistance, the content of each component of the fluoroelastomer, in parts by weight, is:

[0046] Binary fluororubber F26 100 parts

[0047] Magnesium oxide (activity 120) 4 parts

[0048] Calcium hydroxide 6 parts

[0049] Calcium silicate 20 parts

[0050] Bisphenol AF 2 parts

[0051] 0.5 parts of benzyl triphenylphosphorous chloride

[0052] Multifunctional additive LCA 3 parts

[0053] 1 part organic wax

[0054] 1,1,8,8-tetramethyl 3,5,7-trifluoropropylmethylsiloxane-1,3-ethyl diundecanoate 12 parts

[0055] The preparation method of the above-mentioned fluoroelastomer with excellent low temperature resistance and liquid resistance mainly includes the following steps: (1) adding an appropriate amount of reinforcing filler, plasticizer, vulcanizing agent, accelerator, multifunctional additive LCA, organic wax and Fluorosilane ester is mixed for later use;

[0056] (2) Add fluororubber r...

Embodiment 2

[0058] A fluoroelastomer with excellent low temperature resistance and liquid resistance, the fluorosilane ester in each component of the fluoroelastomer is replaced by 1,1,8,8-tetramethyl-3,5,7-tri Fluoropropylmethylsiloxane-1,3-butyl diundecanoate, the number of addition parts became 12.2. All the other components and preparation method are the same as in Example 1.

Embodiment 3

[0060] A fluoroelastomer with excellent low temperature resistance and liquid resistance, the fluorosilane ester in each component of the fluoroelastomer is replaced by 1,1,8,8-tetramethyl-3,5,7-tri Fluoropropylmethylsiloxane-1-ethyl acetate, content changed to 10.3. All the other components and preparation method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com