Mixture for automobile high-speed rotation oil seals

A high-speed rotation and oil-sealing technology, applied in the field of polymer compound processing, can solve the problems of late start of application research and intensified efforts, and achieve the effect of optimizing formulation system, improving thermal conductivity and thermal conductivity.

Inactive Publication Date: 2015-02-04

ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

View PDF3 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The applied research in related fields in our country started relatively late, and the current research in this field still needs to be strengthened

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

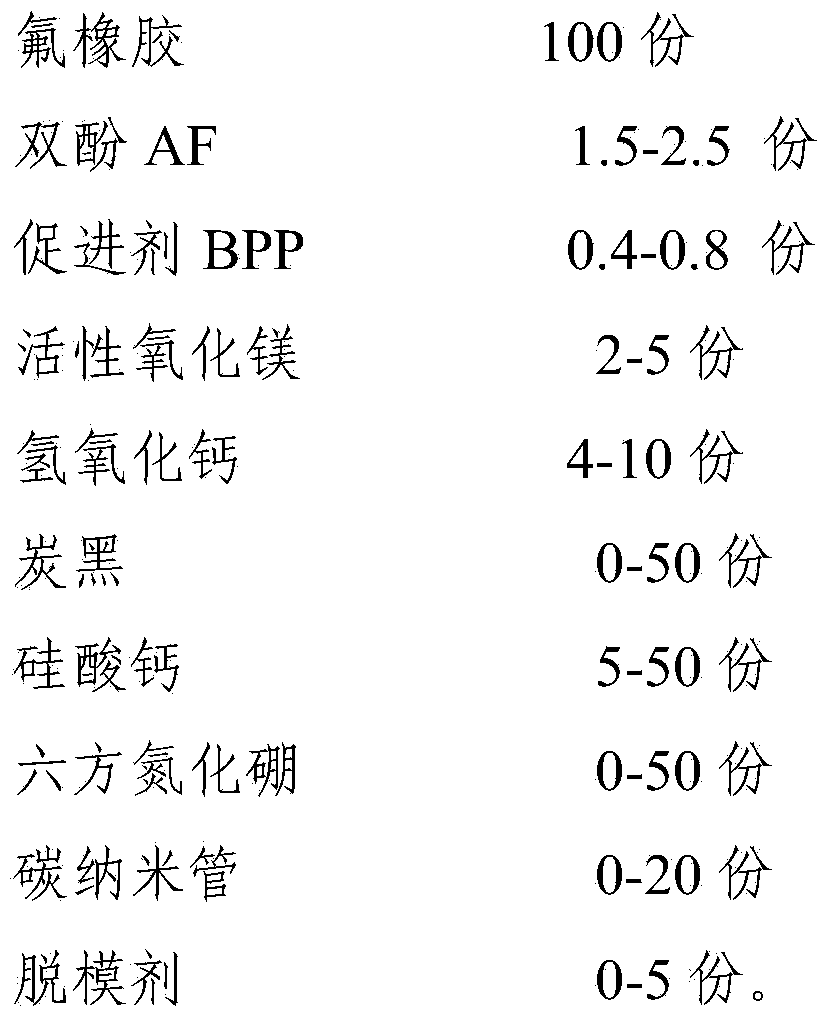

Embodiment 1

[0026]

[0027] The above raw materials are kneaded by an open mill to obtain fluorine compounded rubber.

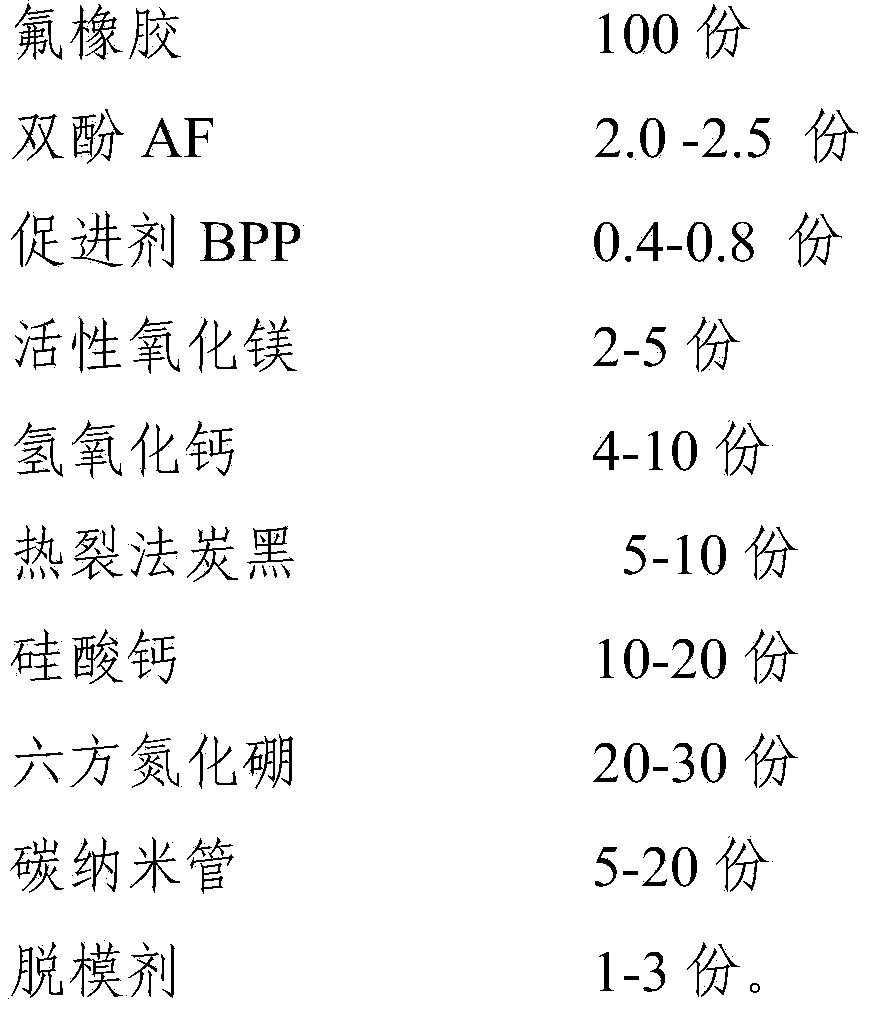

Embodiment 2

[0029]

[0030]

[0031] The above raw materials are kneaded by an open mill to obtain fluorine compounded rubber.

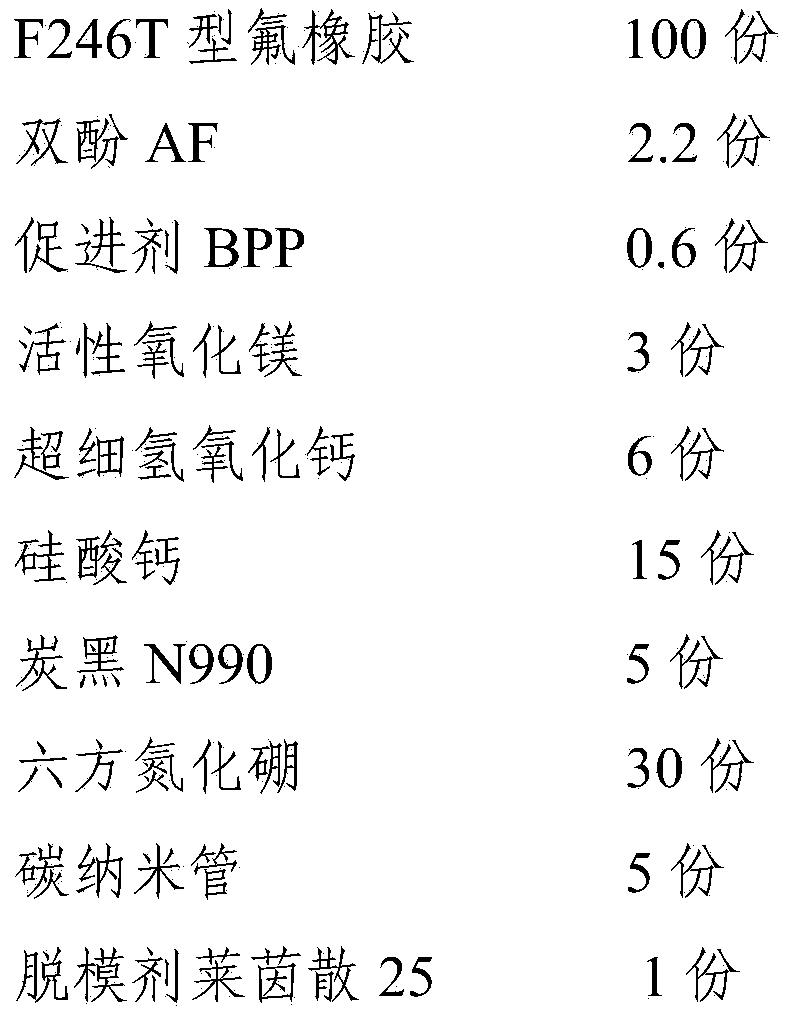

Embodiment 3

[0033]

[0034] The above raw materials are kneaded by an open mill to obtain fluorine compounded rubber.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the field of organic compound processing, and provides a mixture for automobile high-speed rotation oil seals, which is prepared from the following components in parts by weight: 100 parts of fluororubber, 1.5-2.5 parts of bisphenol AF, 0.4-0.8 part of accelerator BPP, 2-5 parts of active magnesium oxide, 4-10 parts of calcium hydroxide, 0-50 parts of carbon black, 5-50 parts of calcium silicate, 0-50 parts of hexagonal boron nitride, 0-20 parts of carbon nanotube and 1-3 parts of mold release agent. By adopting the fluororubber F246 (the Mooney viscosity is 100-150) as the base unvulcanized rubber and optimizing the formula system, the physical and mechanical properties of the vulcanized fluororubber of the original formula are basically unchanged. The two different types of heat-conducting fillers are compounded to enhance the heat conductivity coefficient of the compounded rubber under the synergic actions, and the heat-conducting property of the vulcanized rubber product for manufacturing is obviously enhanced.

Description

technical field [0001] The invention belongs to the processing field of polymer compounds, and in particular relates to a rubber compound for vulcanization. Background technique [0002] Viton was developed in the 1950s to meet the needs of the aviation industry for high-performance sealing, and was quickly applied to the automotive industry, chemical industry and other fields. According to foreign statistics, the amount of fluorine rubber used in the automobile industry accounts for more than 60% of the world's total fluorine rubber, and the rapid development of the automobile industry has also driven the fluorine rubber industry. Fluorine rubber has the characteristics of high temperature resistance, oil resistance and solvent resistance, and good physical and mechanical properties, especially the outstanding high temperature and low pressure denaturation performance, making it the preferred material for automotive oil seals. [0003] The thermal conductivity of fluorine ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/16C08K13/04C08K7/24C08K5/13C08K3/22C08K3/04C08K3/34C08K3/38

CPCC08L27/16C08K2201/003C08K2201/004C08K2201/011C08L91/06C08K13/04C08K7/24C08K3/34C08K3/04C08K2003/2206C08K2003/222C08K2003/385

Inventor 赵研邢华艳张建新刘斌

Owner ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com