A kind of production method of shoe sole

A production method and hard material technology, applied in footwear, other home appliances, home appliances, etc., can solve problems such as laboriousness, inability to bend the forefoot, and easy fatigue of the feet, so as to maintain physical and mechanical properties and save mold costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

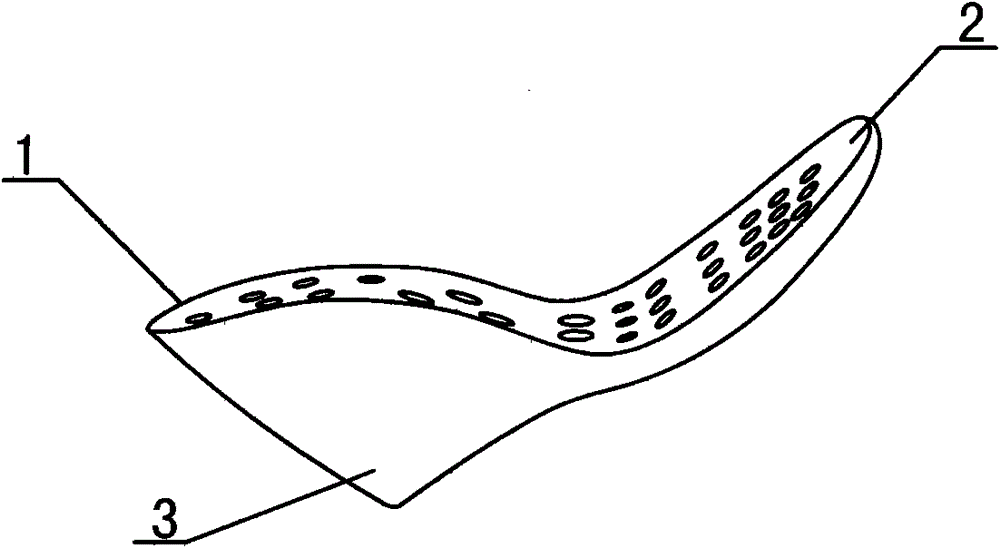

[0016] like figure 1 Shown, the production method of the sole described in the embodiment of the present invention, its main steps comprise:

[0017] (1) Divide the injection material into two parts. Firstly prepare the respective raw materials for the hard material 1 of the rear part and the soft material 2 of the front part respectively. The hard material 1 of the rear part is composed of mixed isocyanate, mixed polyol and additional materials Composition, the additional material includes amine catalyst, metal catalyst, ethylene glycol, talc, foaming agent, color paste, and the latter part of the hard material 1 is a total of 100 parts of all raw materials. The mass fraction of the above additional materials (except color paste) is in order It can be 1-1.2%, 0.3-0.5%, 5-6%, 8-10%, 1-1.2%; the front part of the soft material 2 is composed of isocyanate, polyol and additional materials. Including amine, ethylene glycol, foaming agent, color paste, all the raw materials of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com