Acid-proof and high temperature-resistant adhesive

A technology for adhesives and high temperature resistance, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of affecting structural durability, affecting metal adhesion, and acrylic glue has a strong taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described further:

[0020] The present invention is composed of A component and B component:

[0021] The composition and mass of component A are:

[0022] 107 silicone rubber 3~4 parts,

[0023] Inorganic nanomaterials 3 to 6 parts,

[0024] Auxiliary 0~4 parts;

[0025] The composition and mass of component B are:

[0026] 3-4 parts of 201 silicone oil,

[0027] 3-4 parts of imported carbon black,

[0028] Thixotropic agent 1~2 parts,

[0029] 1 to 2 parts of plasticizer,

[0030] Chain extender 0.5~1 part,

[0031] 1-2 parts of cross-linking agent,

[0032] Coupling agent 0.2~1 part,

[0033] Catalyst 0.1~A component.

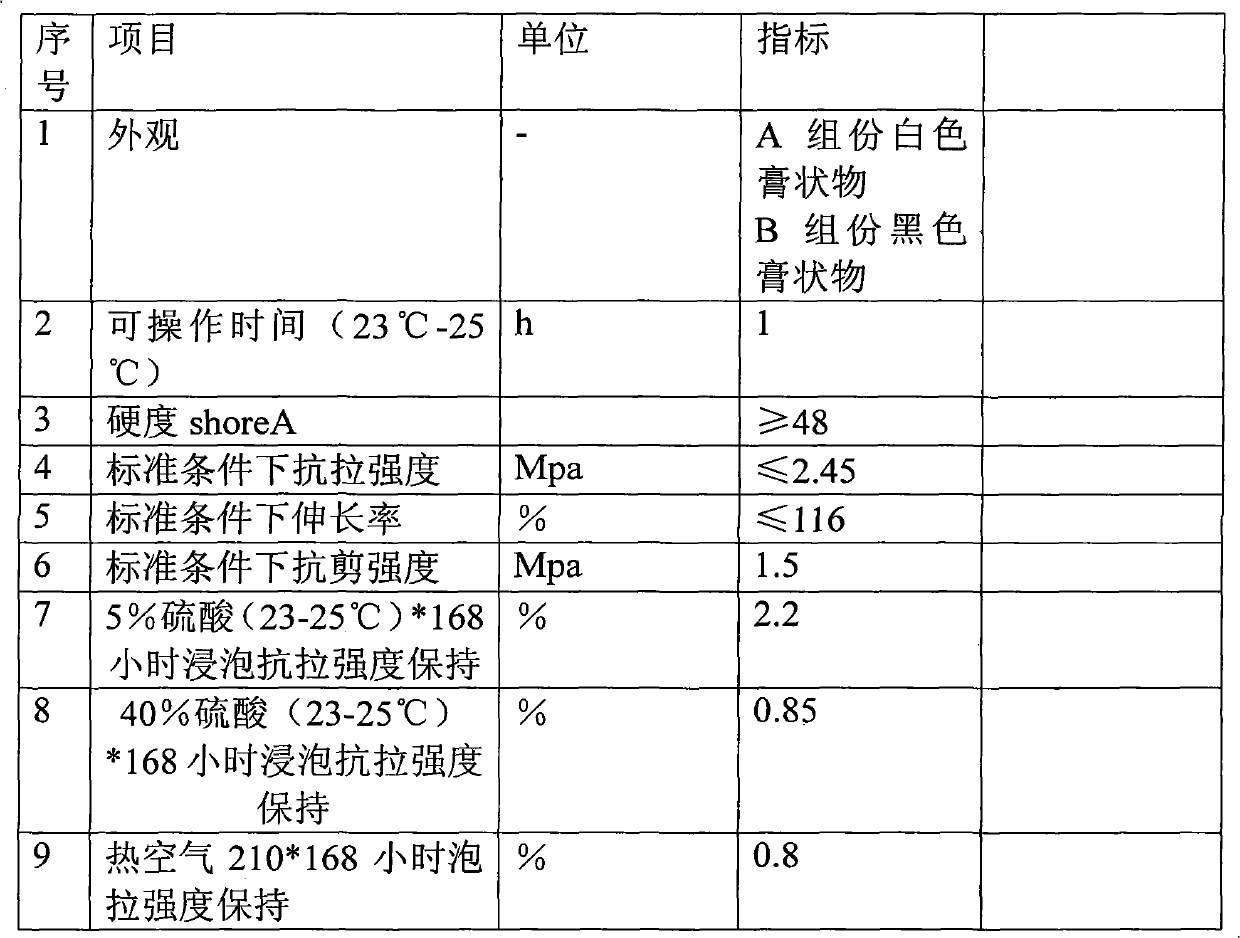

[0034] Main performance indicators:

[0035]

[0036] How to use: 1. Glue compounding: The recommended ratio is component A: component B = 12~13:1. When the working temperature is 23-25℃, the operating time is 1 hour. If you need to speed up or slow down the curing time, you can increase or decrease the amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com