Modified fluororubber rubber compound and preparation method thereof

A technology of modified fluororubber and rubber compound, which is applied in the field of material science and engineering, can solve the problems of complex synthesis process of perfluoroether rubber, failure to meet requirements, high production cost, etc., and achieve excellent resistance to alcohol fuels and chemical media, Reduced Low Temperature Performance, Affordable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

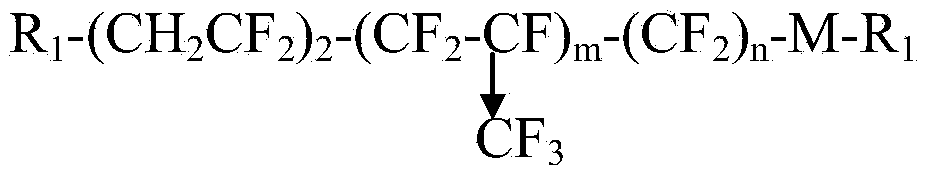

Method used

Image

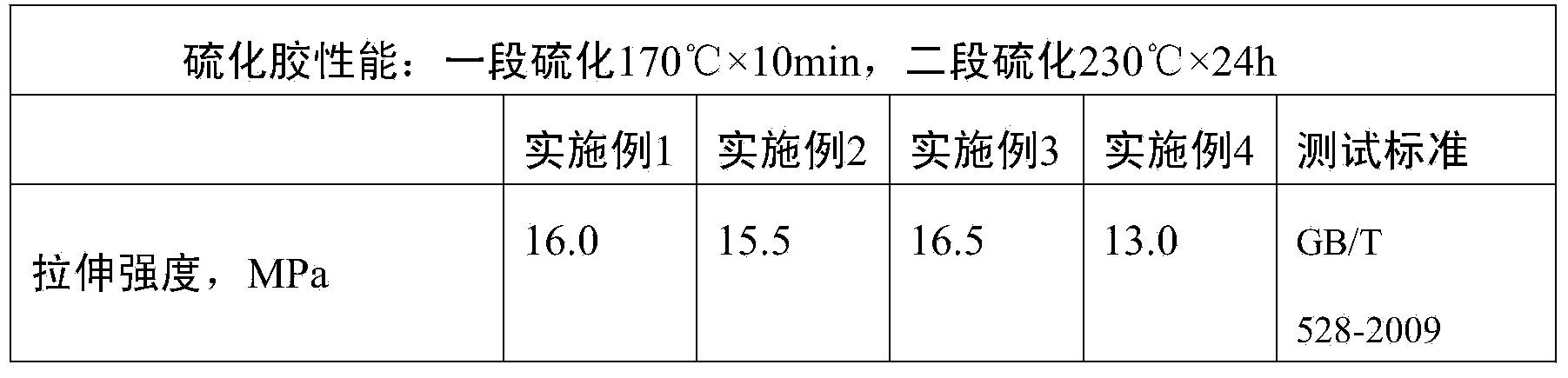

Examples

Embodiment 1

[0043] Preparation of Embodiment 1 Fluorine Rubber Compound (1)

[0044] The formulation of fluororubber compound with low temperature resistance and chemical medium is as follows.

[0045] Modified binary fluororubber (REM260) 100

[0048] Carbon black filler 20

[0050] Release agent 1.5

[0051] Bisphenol AF 2.0

[0052] Benzyltriphenylphosphonium chloride 0.4

[0053] Modified diatomaceous earth 5

[0054] Double 2.5 1.0

[0055] TAIC 2.0

[0056] The above-mentioned release agent is WS280.

[0057] The above-mentioned modified diatomite is obtained by physically treating diatomite and silica with an aminosilane coupling agent containing four functional groups.

Embodiment 2

[0058] Preparation of embodiment 2 fluorine rubber compound (2)

[0059] The formulation of fluororubber compound with low temperature resistance and chemical medium is as follows.

[0060] Modified binary fluororubber (REM260) 100

[0063] Carbon black filler 25

[0065] Release agent 2.0

[0066] Bisphenol AF 2.2

[0067] Benzyltriphenylphosphonium chloride 0.5

[0068] Modified diatomaceous earth 7

[0069] Double 2.5 1.2

[0070] TAIC 2.4

[0071] The above-mentioned release agent is Rhine Powder

[0072] The above-mentioned modified diatomite is obtained by physical treatment of diatomite and silica powder through aminosilane coupling agent containing four functional groups.

Embodiment 3

[0073] Preparation of Embodiment 3 Fluorine Rubber Compound (3)

[0074] The formulation of fluororubber compound with low temperature resistance and chemical medium is as follows.

[0075] Modified binary fluororubber (REM260) 100

[0078] Carbon black filler 30

[0080] Release agent 3.0

[0081] Bisphenol AF 2.5

[0082] Benzyltriphenylphosphonium chloride 0.6

[0083] Modified diatomaceous earth 7

[0084] Double 2.5 1.5

[0085] TAIC 2.8

[0086] The above mold release agent is obtained by mixing Rhine powder and WS280 in 1:1 parts by weight.

[0087] The above-mentioned modified diatomite is obtained by physical treatment of silica and silica powder through aminosilane coupling agent containing four functional groups.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com