Turbine booster hose of fluorine rubber, oil-resisting silicon rubber and silicon rubber and its production

A technology of turbocharging and silicone rubber, applied in hoses, pipes, mechanical equipment, etc., can solve the problems of high temperature resistance, heat oil resistance, poor penetration resistance, etc., to prolong service life, improve production efficiency, and improve blasting The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

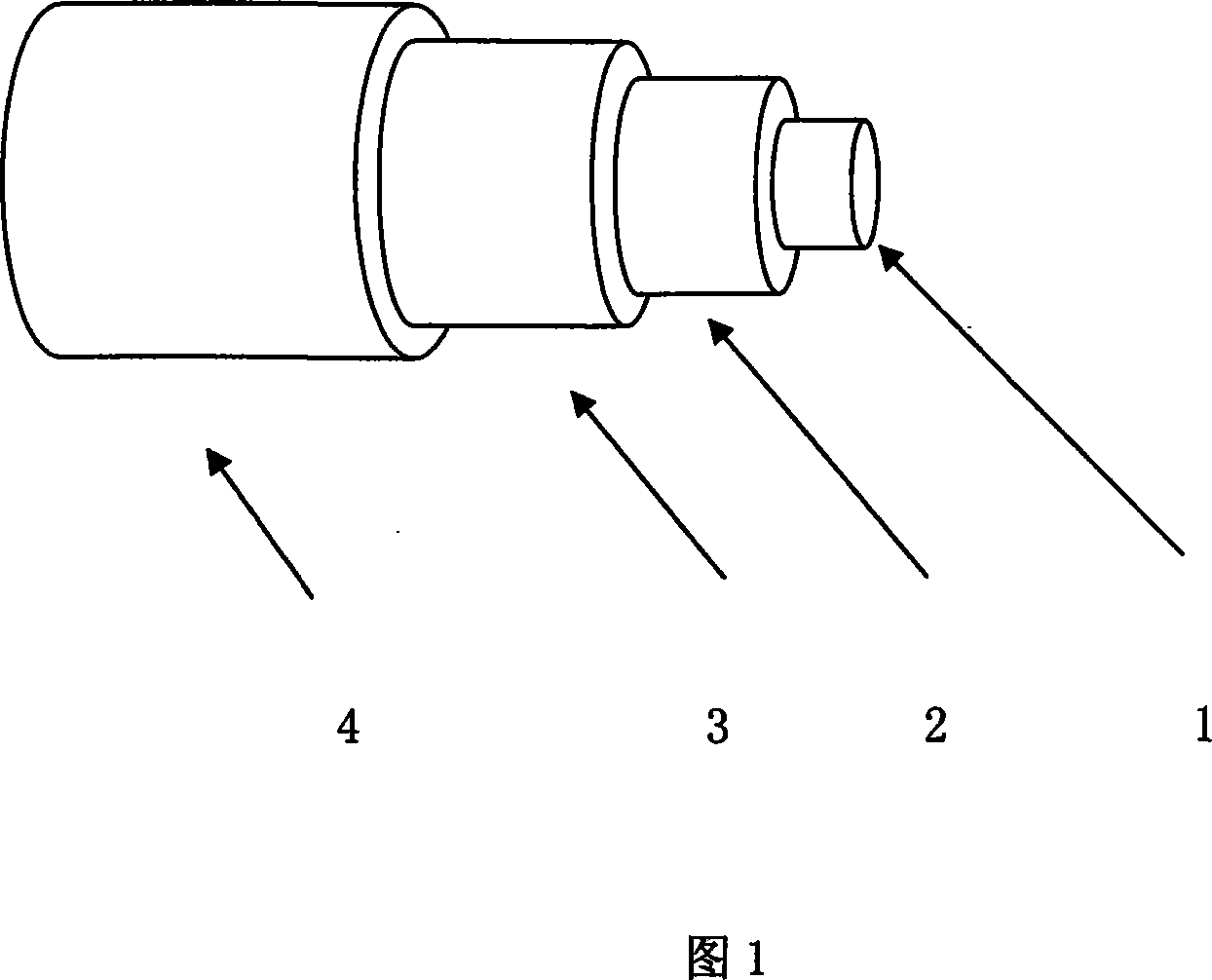

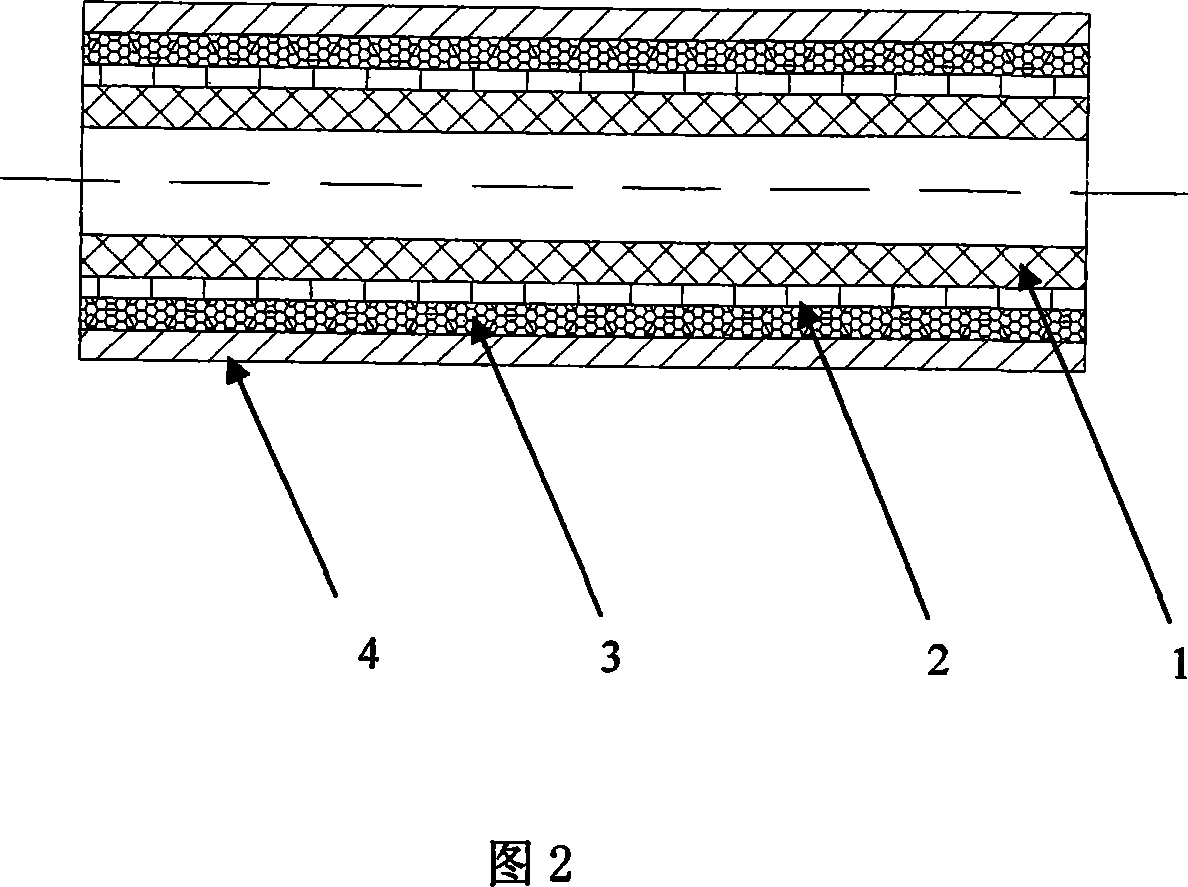

[0019] To produce a turbo hose with an inner diameter of 50±0.5mm×4±0.5mm×400±3mm as shown in Figure 1, the steps are as shown in Figure 2:

[0020] 1) Tube embryo manufacturing process

[0021] Extrude inner rubber and middle rubber: Extrude fluorine rubber and silica gel on the dual compound extruder at the same time, set the extrusion temperature of inner rubber fluorine rubber to 60°C, 50°C, 50°C, 50°C, 50°C, medium rubber silicone The extrusion temperatures are 40°C, 30°C, 30°C, 30°C, 30°C.

[0022] The reinforcement layer is aramid thread.

[0023] Extrude the outer rubber: select the appropriate machine needle and mouth shape to directly extrude the silicone compound rubber, and set the extrusion temperature of the outer rubber to 40°C, 30°C, 30°C, 30°C, and 30°C.

[0024] 2) Vulcanization:

[0025] Carry out primary vulcanization in the vulcanization tank, the parameters of the first stage of vulcanization: the temperature is 170 ° C, the time is 20 minutes, and the...

Embodiment 2

[0028] To produce a turbocharged rubber hose with an inner diameter of 60±1mm×6±0.5mm×600±3mm, the method steps are as shown in Example 1, the difference is:

[0029] Set the extrusion temperature of inner rubber fluorine rubber to 80°C, 70°C, 70°C, 70°C, 70°C, and the extrusion temperature of medium rubber silicone rubber to 50°C, 40°C, 40°C, 40°C, 40°C.

[0030] The reinforcement layer is aramid thread.

[0031] The outer rubber extrusion temperature is 50±5°C, 40±5°C, 40±5°C, 40±5°C, 40±5°C.

[0032] Parameters of one-stage vulcanization: temperature is 180°C, time is 10min; parameters of second-stage vulcanization: temperature is 200°C, time is 1h.

[0033]

Embodiment 3

[0035] To produce a turbocharged rubber hose with an inner diameter of 20±1mm×3±0.5mm×400±3mm, the method steps are as shown in Example 1, the difference is:

[0036] Set the extrusion temperature of inner rubber fluorine rubber to 50°C, 40°C, 40°C, 40°C, 40°C, and the extrusion temperature of medium rubber silicone rubber to 20°C, 20°C, 20°C, 20°C, 20°C.

[0037] The reinforcement layer is aramid thread.

[0038] The extrusion temperature of the outer rubber is 20±5°C, 20±5°C, 20±5°C, 20±5°C, 20±5°C.

[0039] Parameters of one-stage vulcanization: temperature is 130°C, time is 60min; parameters of second-stage vulcanization: temperature is 150°C, time is 4h.

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com