Automobile fuel oil evaporative rubber tube with composite structure and manufacturing method for automobile fuel oil evaporative rubber tube

A composite structure and manufacturing method technology, which is applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of accelerating the aging of the outer rubber hose material, unfavorable environmental protection requirements for fuel emissions, and poor fuel resistance of the outer rubber. Achieve the effect of saving production cost, improving enterprise operating efficiency, and good fuel resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

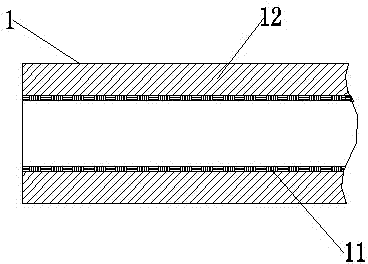

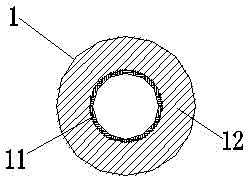

[0047] Embodiment one, such as Figure 1 to Figure 2 As shown, a composite structure automotive fuel evaporation rubber hose of the present invention includes a rubber hose body 1, and the rubber hose body 1 is an inner tube rubber made of fluorine rubber containing bisphenol vulcanizing agent, magnesium oxide, calcium hydroxide, carbon black and accelerator The layer 11 is composed of the outer tube rubber layer 12 made of chloroether rubber containing vulcanizing agent, carbon black, plasticizer, magnesium oxide and anti-aging agent, and the inner tube rubber layer 11 and the outer tube rubber layer 12 are integrated through a compound extruder Adhesive compound extrusion. Also contain stearic acid and calcium carbonate in its outer tube rubber layer 12.

[0048] A kind of manufacture method of composite structure automobile fuel evaporation hose of the present invention comprises the following steps:

[0049] step 1, The sizing materials of the inner and outer tube rubbe...

Embodiment 2

[0076] Embodiment 2, a composite structure automotive fuel evaporation rubber hose of the present invention, including a rubber hose body 1, the rubber hose body 1 is composed of an anti-permeation fluorine rubber inner tube rubber layer 11 and an ECO outer tube rubber layer 12 through a T-shaped compound extruder. Adhesive compound extrusion. Its manufacturing method comprises the following steps:

[0077] step 1, The sizing materials of the inner and outer tube rubber layers are sent to the internal mixer for mixing respectively according to the following parts by weight, and the parts by weight of each raw material of the rubber layer of the inner tube are:

[0078] Fluorine rubber 100 parts by weight

[0079] Bisphenol AF vulcanizing agent 2.5~4.0 parts by weight

[0080] Accelerator BPP 0.2~0.4 parts by weight

[0081] Magnesium oxide 2.0~5.0 parts by weight

[0082] Calcium hydroxide 5.0~8.0 parts by weight

[0083] Carbon black N990 20.0-40.0 parts by weight

[0...

Embodiment 3

[0104] Embodiment 3, a composite structure automotive fuel evaporation hose of the present invention, including a hose body 1, the hose body 1 is integrally glued and compounded by an inner tube rubber layer 11 and an outer tube rubber layer 12 through a T-shaped compound extruder. Its manufacturing method comprises the following steps:

[0105] step 1, The sizing materials of the inner and outer tube rubber layers are sent to the internal mixer for mixing respectively according to the following parts by weight, and the parts by weight of each raw material of the rubber layer of the inner tube are:

[0106] Fluorine rubber 100 parts by weight

[0107] 3 parts by weight of bisphenol AF vulcanizing agent

[0108] Accelerator BPP 0.3 parts by weight

[0109] Magnesium oxide 3 parts by weight

[0110] Calcium hydroxide 6 parts by weight

[0111] Carbon black N990 30 parts by weight

[0112] The parts by weight of each raw material of its outer tube rubber layer are:

[0113...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com