Acidproof, alkali-proof and hydrogen-sulphide-corrosion-resistant aflas composite

A technology of tetrapropylene fluoride rubber and rubber composition, which is applied in the field of tetrapropylene fluoride rubber composition and rubber products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

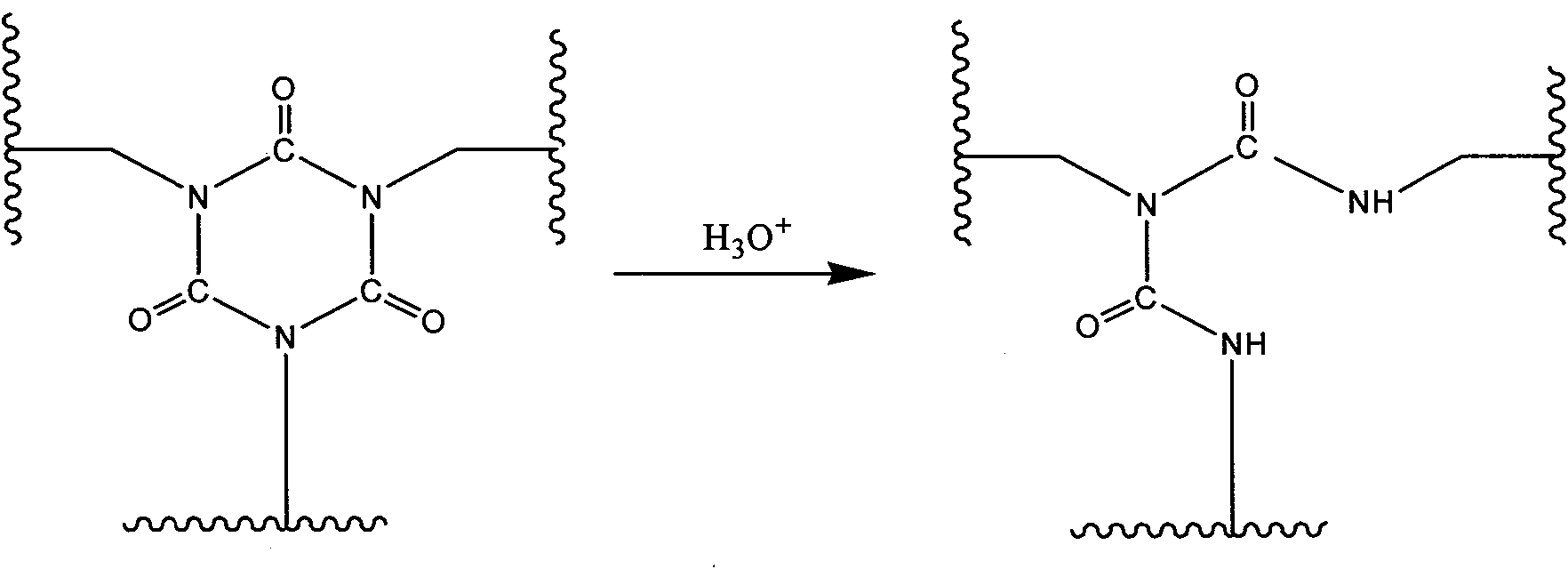

Method used

Image

Examples

Embodiment 1-8 and comparative example 1

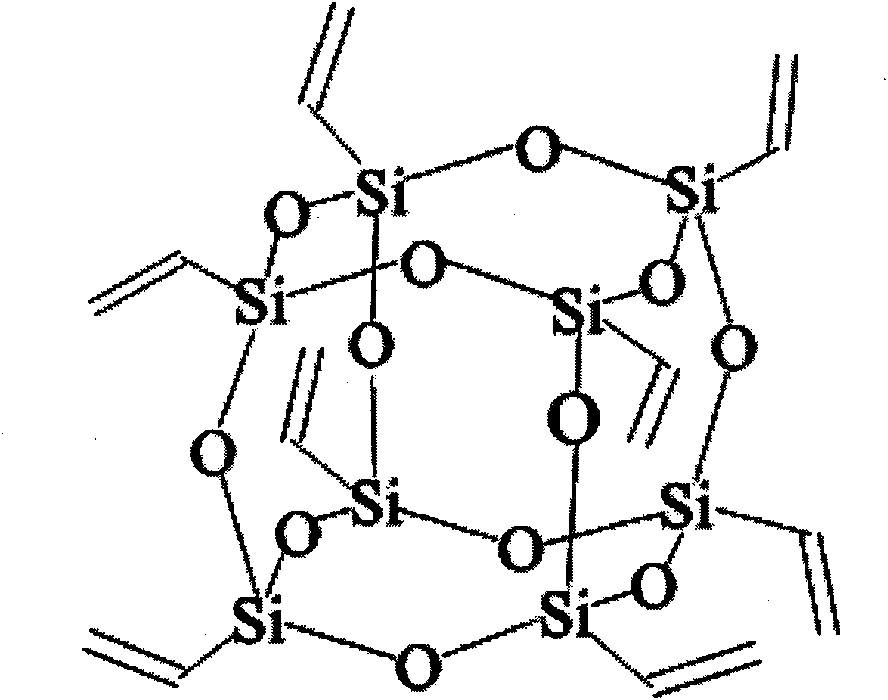

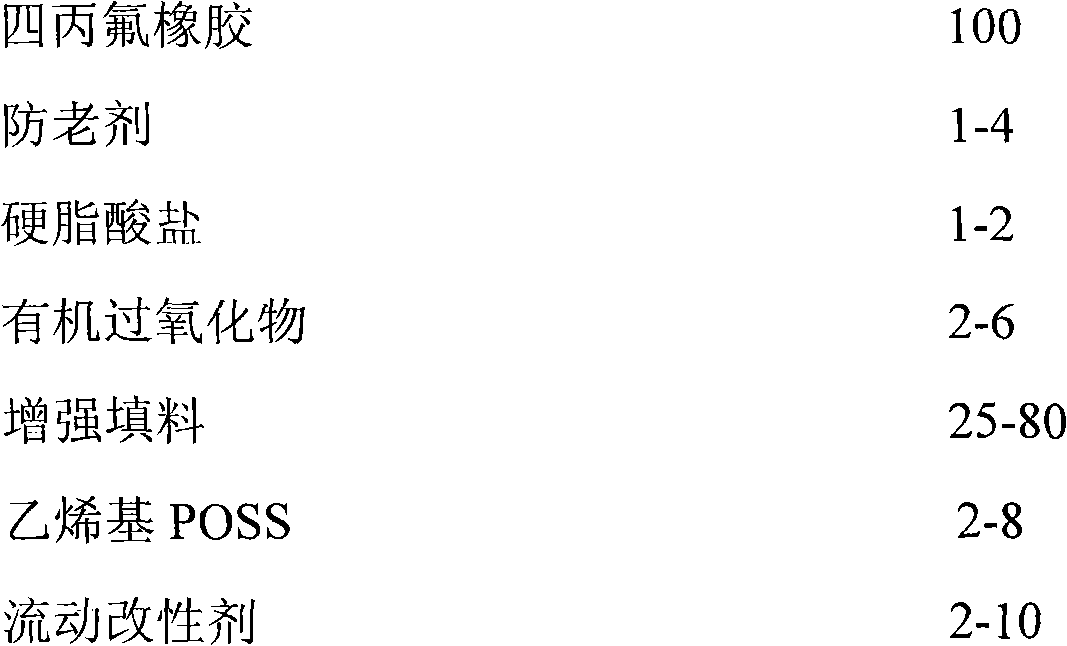

[0015] The tetrapropyl fluorine rubber (aflas100H) that adopts Asahi Glass to produce and the tetrapropyl fluorine (TP-2) that 3F company produces are main body materials, take it as 100 weight parts, coordinate preparation according to table 1 and meet the requirements of the present invention. Dicumyl oxide (DCP) is the main crosslinking agent, vinyl POSS is the auxiliary crosslinking agent, hard carbon black N330 and N550 are the reinforcing materials, and coumarone resin is the rubber composition of the plasticizer, namely Examples 1-8. Adopt similar coordination, make comparative example 2 with TAIC as the cross-assist agent.

[0016] The hydrogen sulfide, hydrochloric acid and sodium hydroxide corrosion tests were carried out on the vulcanized test pieces, and the results after corrosion are shown in Table 2. As can be seen from Table 2, the present invention can obtain tetrapropylene fluororubber used under hydrogen sulfide, hydrochloric acid and alkaline conditions. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com