High-thermal-conductivity electromagnetic shielding polyether-ether-ketone composite material with isolation structure as well as preparation method and application thereof

A polyetheretherketone and electromagnetic shielding technology is applied in the field of high thermal conductivity electromagnetic shielding polyetheretherketone composite material and its preparation, and can solve the problems of inability to meet the application requirements of shielding performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

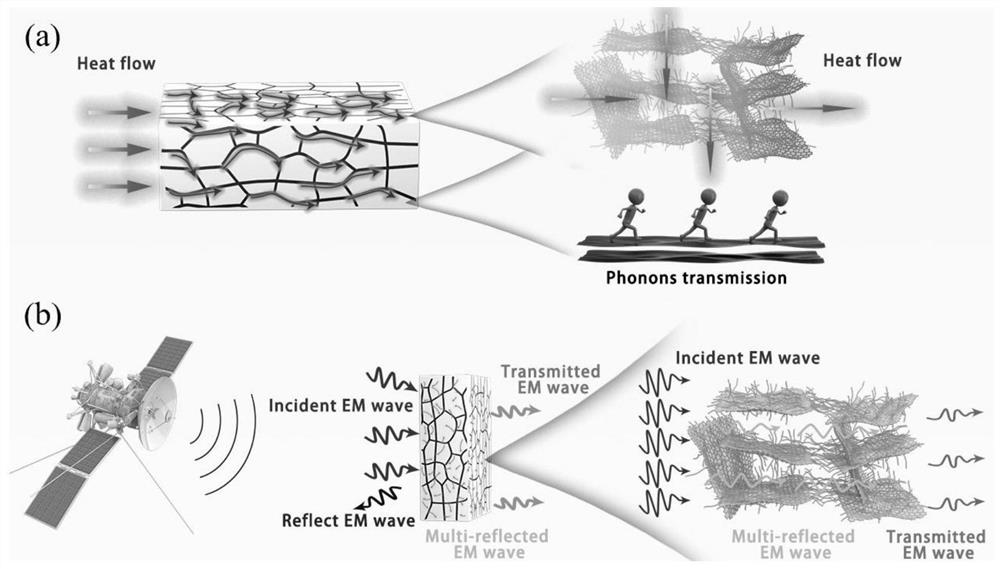

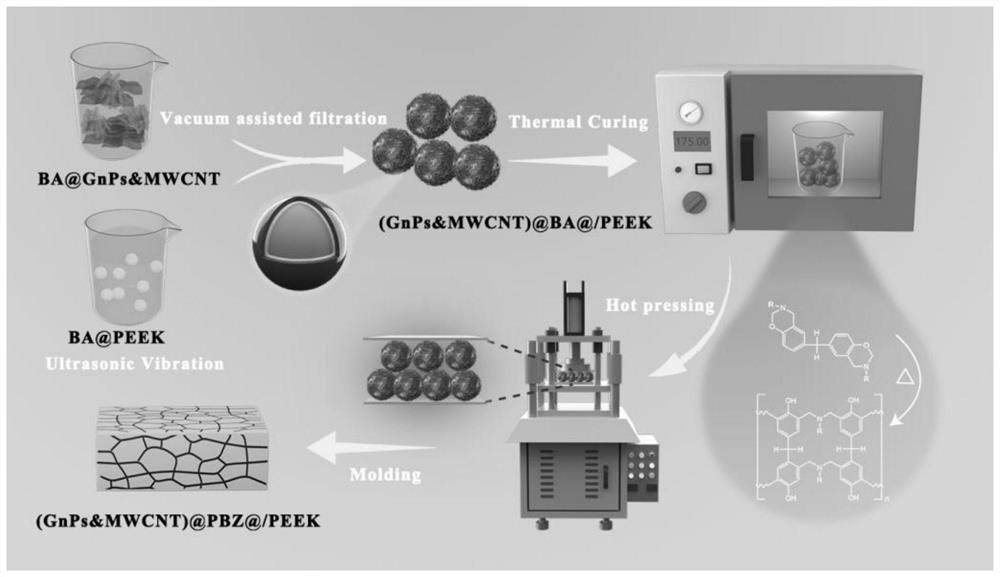

[0032] The invention provides a method for preparing a high thermal conductivity electromagnetic shielding polyether ether ketone composite material with an isolation structure, comprising the following steps:

[0033] (1) Mix multi-walled carbon nanotubes, graphene nanosheets, benzoxazine and a soluble benzoxazine solvent for ultrasonic modification to obtain a modified hybrid filler dispersion;

[0034] (2) Mix polyether ether ketone, benzoxazine and soluble benzoxazine solvent for ultrasonic modification to obtain a modified polyether ether ketone dispersion;

[0035] (3) mixing the modified hybrid filler dispersion and the modified polyether ether ketone dispersion, and performing vacuum shearing-assisted mixing to obtain polyetheretherketone composite particles;

[0036] (4) The polyether ether ketone composite particles are solidified and crosslinked and melted and hot-pressed sequentially to obtain a high thermal conductivity electromagnetic shielding polyether ether ke...

Embodiment 1

[0050] use figure 2 As shown in the process flow chart, a high thermal conductivity electromagnetic shielding polyether ether ketone composite material with isolation structure is prepared by vacuum-assisted method, thermal cross-linked polymer modification method and melt hot pressing method. The specific steps are as follows:

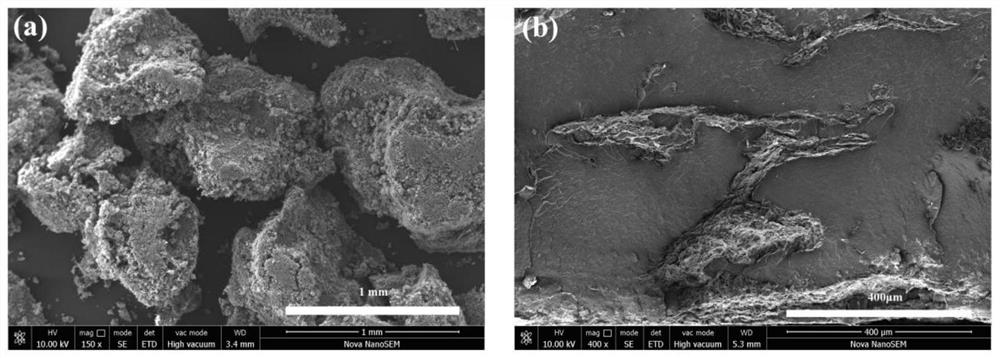

[0051] Add 0.05g MWCNTs and 0.2g GnPs to 250mL PBZ acetone solution with a concentration of 1.25wt%, mix and disperse evenly, and ultrasonicate in an ultrasonic oscillator at 60MHz and room temperature for 3h to obtain a modified hybrid filler dispersion. Add 9.75 g of PEEK with a particle size of 200 mesh into 450 mL of PBZ acetone solution with a concentration of 1.25 wt %, and ultrasonicate for 1 h at 60 MHz in an ultrasonic oscillator at room temperature to obtain a modified polyether ether ketone dispersion. The modified hybrid filler dispersion and the modified polyetheretherketone dispersion are mixed for slow-release vacuum-assisted filtratio...

Embodiment 2

[0053] The high thermal conductivity electromagnetic shielding polyether ether ketone composite material with isolation structure was prepared according to the method of Example 1, and the preparation conditions of Examples 2-6 are shown in Table 1.

[0054] Table 1 Preparation conditions of Examples 1-6

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com