SIBR integrated rubber containing amino group, integrated rubber composite material and preparation method thereof

A technology that integrates rubber and groups, applied in tire parts, transportation and packaging, special tires, etc., can solve the problems of difficult structure control, difficult amine functionalization conversion efficiency, and difficult to grasp the relationship between structure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

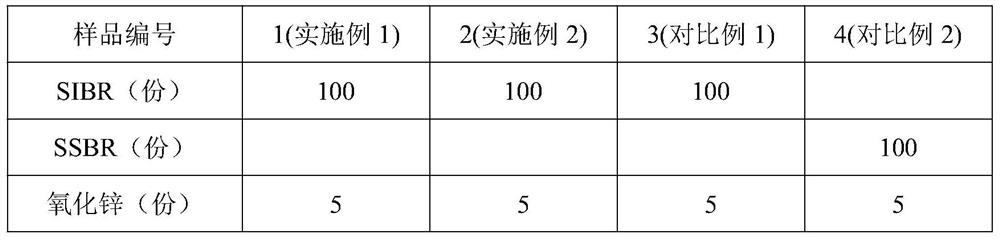

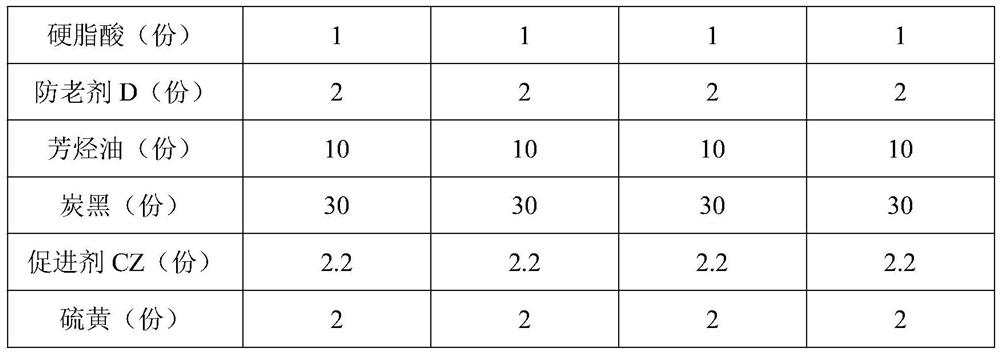

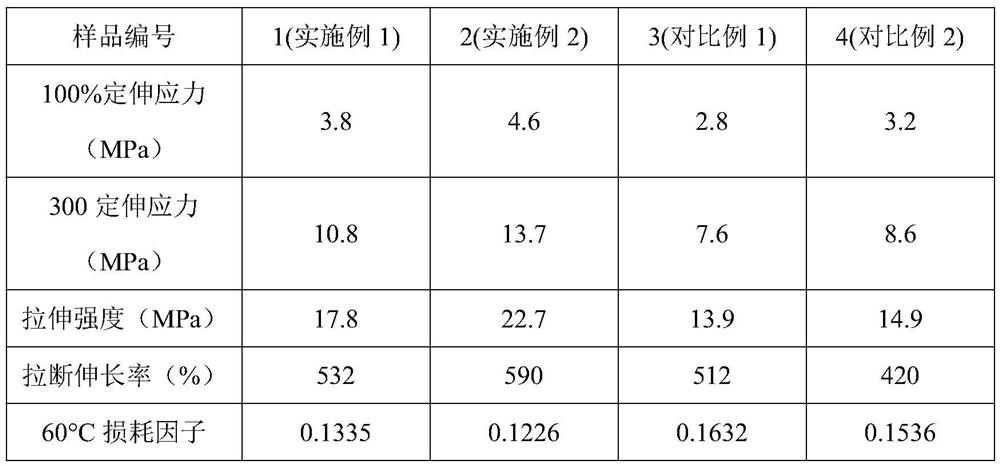

Embodiment 1

[0037] Under the protection of argon, 100ml of solvent benzene, 200ml of cyclohexane, 1-[4-(N,N-dimethylamino)phenyl]-1'- 5g phenylethylene, 0.2g styrene, heat up to 60°C, turn on and stir until the 1,1-diphenylethylene derivatives containing amino groups (amino DPE derivatives, the same below) are completely dissolved, according to the design Molecular weight 200kg / mol Add initiator sec-butyllithium, react for 60min; add tetramethylethylenediamine (TMEDA) 0.1g, styrene 7.8g, isoprene 16g, butadiene 16g at the same time, continue to react for 24h, The addition of isopropanol was terminated, the reaction mixture was precipitated in excess anhydrous methanol, and the resulting polymer was dried in a vacuum oven to constant weight. The product structure analysis results are as follows: based on 100% of the total amount of the tetrapolymer, the mass percentage of bound styrene in the tetrapolymer is 18.6%, 1-[4-(N,N-dimethylamino)phenyl ]-1'-phenylethylene content mass percentage...

Embodiment 2

[0039] Under the protection of argon, add 100ml of solvent benzene, 200ml of cyclohexane, and 1,1'-bis[4-(N,N-dimethylamino)phenyl] to a 1L polymerization reactor that has been dried and deoxygenated Ethylene 10g, Tetramethylethylenediamine (TMEDA) 0.1g, Styrene 7.5g, Isoprene 16g, Butadiene 16g, heat up to 60°C, turn on and stir until the amine-based DPE derivative is completely dissolved, according to the designed molecular weight Add monomer 1,1-diphenylethylene derivative, styrene 0.5g and butyllithium equimolar reaction liquid initiator at 200kg / mol, react for 24h, add isopropanol to terminate, and the reaction mixture is precipitated in excess anhydrous methanol , and the resulting polymer was dried in a vacuum oven to constant weight. The product structure analysis results are as follows: based on 100% of the total amount of the tetrapolymer, the mass percentage of bound styrene in the tetrapolymer is 18.3%, 1,1'-bis[4-(N,N-dimethylamine Base) phenyl] ethylene content ...

Embodiment 3

[0041] Under the protection of argon, add 100ml of solvent benzene, 260ml of cyclohexane, and 1,1'-bis[4-(N,N-diethylamino)phenyl] to a 1L polymerization reactor that has been dried and deoxygenated Ethylene 12.5g, styrene 1g, heat up to 50°C, turn on and stir until the amine-based DPE derivative is completely dissolved, add the initiator n-butyllithium according to the design molecular weight of 100kg / mol, and react for 60min; then add tetramethylethylenediamine in sequence (TMEDA) 0.093g, styrene 3g, isoprene 12g, butadiene 24g, continue to react for 24h, add isopropanol to terminate, the reaction mixture is precipitated in excess anhydrous methanol, and the obtained polymer is dried in a vacuum oven to constant weight. The product structure analysis results are as follows: based on 100% of the total amount of the tetrapolymer, the mass percentage of bound styrene in the tetrapolymer is 10.3%, 1,1'-bis[4-(N,N-diethylamine Base) phenyl] ethylene content mass percentage is 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com