Method for preparing polymer nanocomposite through ultrasonic-assisted forced infiltration

A nano-composite material, ultrasonic-assisted technology, applied in the direction of coating, etc., can solve problems such as difficult to uniformly disperse nano-fillers, affect the use, and affect the performance of nano-composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

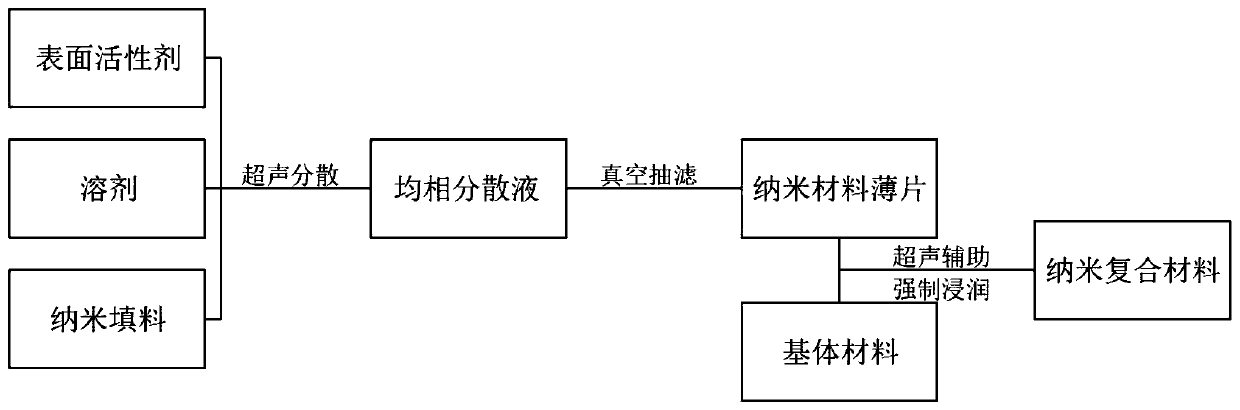

[0027] In this embodiment, carbon nanotube flakes infiltrate polydimethylsiloxane matrix, including the following steps: as figure 1 Shown:

[0028] Ⅰ. Ultrasonic dispersion to prepare a homogeneous dispersion: add 1g of carbon nanotube powder and 3g of sodium lauryl sulfate to deionized water to make a 400ml solution, and use ultrasonic high-frequency oscillation for 60 minutes to make the solute in the solvent Uniformly disperse to prepare a homogeneous dispersion of carbon nanotubes;

[0029] Ⅱ. Preparation of nanomaterial sheets by vacuum filtration: drop 10ml of homogeneous dispersion of carbon nanotubes on a PTFE filter membrane with a diameter of 25mm and a pore size of 200nm, and stack the dispersion on the PTFE filter membrane layer by layer through vacuum filtration After being fully washed and dried, it was peeled off from the nanoporous membrane to obtain carbon nanotube flakes with uniform thickness, such as Figure 3-5 shown;

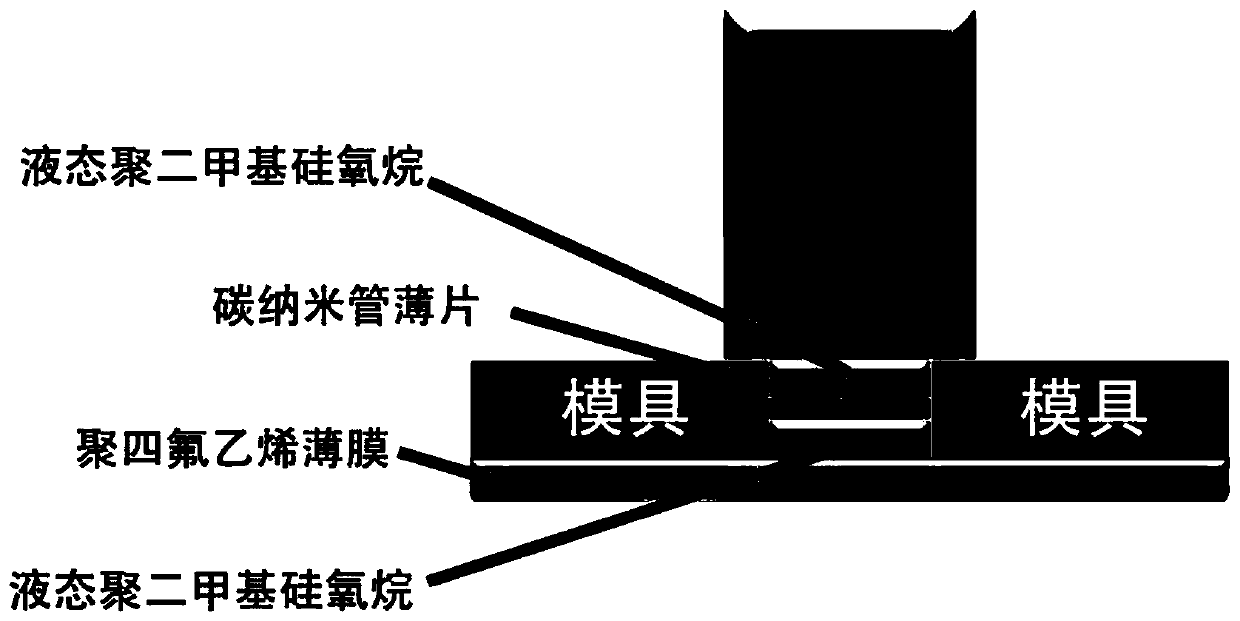

[0030] Ⅲ. Preparation of polymer...

Embodiment 2

[0034] In this embodiment, carbon nanotube flakes infiltrate the polypropylene matrix, including the following steps:

[0035] Ⅰ. Ultrasonic dispersion to prepare a homogeneous dispersion: add 1g of carbon nanotube powder and 3g of sodium lauryl sulfate to deionized water to make a 400ml solution, and use ultrasonic high-frequency oscillation for 60 minutes to make the solute in the solvent Uniformly disperse to prepare a homogeneous dispersion of carbon nanotubes;

[0036] Ⅱ. Preparation of nanomaterial sheets by vacuum filtration: drop 10ml of homogeneous dispersion of carbon nanotubes on a PTFE filter membrane with a diameter of 25mm and a pore size of 200nm, and stack the dispersion on the PTFE filter membrane layer by layer through vacuum filtration After fully washing and drying, it is peeled off from the nanoporous membrane to obtain carbon nanotube flakes with uniform thickness;

[0037] Ⅲ. Ultrasonic-assisted forced infiltration to prepare polymer nanocomposites: The...

Embodiment 3

[0041] In this embodiment, nano-boron nitride flakes infiltrate the epoxy resin matrix, including the following steps:

[0042] Ⅰ. Ultrasonic dispersion to prepare a homogeneous dispersion: add 1g of nano-boron nitride and 3g of sodium dodecyl sulfate to deionized water to make a 400ml solution, and use ultrasonic high-frequency oscillation for 60 minutes to make the solute in the solvent Uniformly disperse to prepare nano boron nitride homogeneous dispersion;

[0043] Ⅱ. Preparation of nanomaterial sheets by vacuum filtration: drop 10ml of nano-boron nitride homogeneously dispersed liquid on a PTFE filter membrane with a diameter of 25mm and a pore size of 200nm, and stack the dispersion liquid layer by layer onto the PTFE filter through vacuum filtration. On the membrane, peel off from the nanoporous membrane after being fully cleaned and dried to obtain nano boron nitride flakes with uniform thickness;

[0044] Ⅲ. Preparation of polymer nanocomposites by ultrasonic-assiste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com