Method for preparing multilayer filler/fluoroether rubber composition through layering method

A technology of fluoroether rubber and composition, which is applied in the field of multi-layer filler/fluoroether rubber composition prepared by lamination method, can solve the problems of poor rubber process adaptability and large energy consumption, and achieve excellent product performance, excellent comprehensive performance, The effect of excellent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

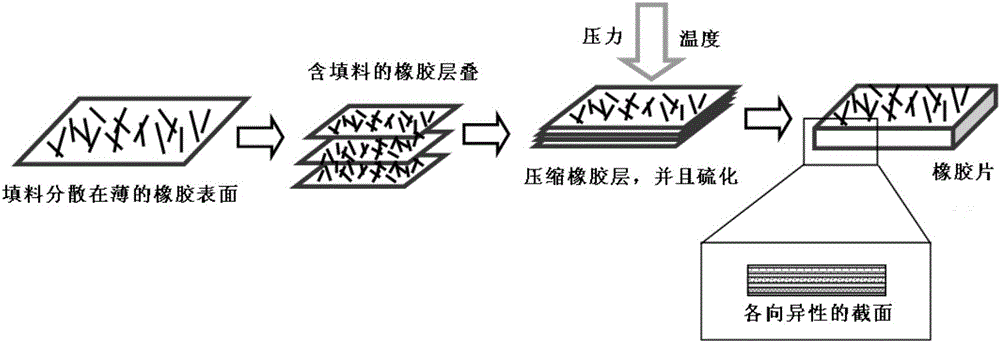

[0032] Such as figure 1 Shown is a schematic diagram of the layer preparation method of the multi-layer filler / fluoroether rubber composition of the present invention. The method of preparing the multi-layer filler / fluoroether rubber composition by the layer-layer method of the present invention specifically includes the following steps:

[0033] (1), preparation of fluoroether rubber film

[0034] Prepare the fluoroether rubber film with a thickness of 0.02-0.2mm by dry method or wet method, wherein the mass ratio of fluoroether rubber is: 100 parts of fluoroether rubber raw rubber, 0-5 parts of acid absorbing agent, and 1 part of vulcanizing agent ~6 parts, co-vulcanizing agent is 1~6 parts.

[0035] The acid absorbing agent is one or a combination of magnesium oxide, calcium oxide, calcium hydroxide, zinc oxide or lead oxide. The vulcanizing agent is 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, dicumyl peroxide, N,N-biscinnamylidene-1,6-hexanediamine, One or a combinati...

Embodiment 1

[0047] 1. According to the formula (quality): 100 parts of fluoroether rubber, 4 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, 2 parts of triallyl isocyanurate Mixing is carried out. After the refined fluorine ether rubber is produced into 0.1-0.3mm thick flakes on the open mill, cut them into pieces, pour them into DMF solvent and stir, and make a 20wt% (mass concentration) DMF solution, then place them upside down on a smooth glass , after leveling, use a roller to drive repeatedly on the surface, keep 0.05mm thick protrusions at both ends of the roller along the circumferential direction, dry at room temperature for 3 days, and obtain a fluoroether rubber film with a thickness of 0.05mm.

[0048] 2. Pour 10 parts of graphene into the spray gun, the pressure of the spray gun is 1MPa, the distance of the spray gun is 20cm, the gas used is air, and spray evenly on the rubber film, and the spray time is 10s.

[0049] 3. Cut the graphene-enriched rubber film into a siz...

Embodiment 2

[0051] 1. According to the formula (parts by mass): 100 parts of fluoroether rubber, 4 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 4 parts of triallyl isocyanurate parts for mixing. The kneaded film was put into a four-roll calender, adjusted by the calender, cooled and shaped to obtain a rubber film with a thickness of 0.08 mm.

[0052] 2. Use a conveyor belt with a moving speed of 50mm / min to transport the carbon black N330. The conveyor belt is located above the film, and a scraper is placed above the end of the conveyor belt. The gap between the scraper and the conveyor belt is controlled to be 0.05mm. At the same time, the rubber film is placed on another conveyer belt with a reverse speed of 10 cm / min to realize continuous dispersion of the filler on the surface of the rubber film.

[0053] 3. Cut the carbon black-enriched rubber film into an area of 50 cm×10 cm. Stack the cut rubber strips in the same direction, and the number of stacked layers is 25. Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com