A preparation method of boron nitride and aluminum nitride co-doped polyimide composite film with high thermal conductivity and high insulation

A polyimide and composite film technology, which is applied in the field of composite film preparation, can solve the problems of application limitation, poor thermal conductivity, insulation and mechanical properties of the polyimide composite film, and achieves improved comprehensive performance and improved electrical properties. Insulation and mechanical properties, the effect of good overall macroscopic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

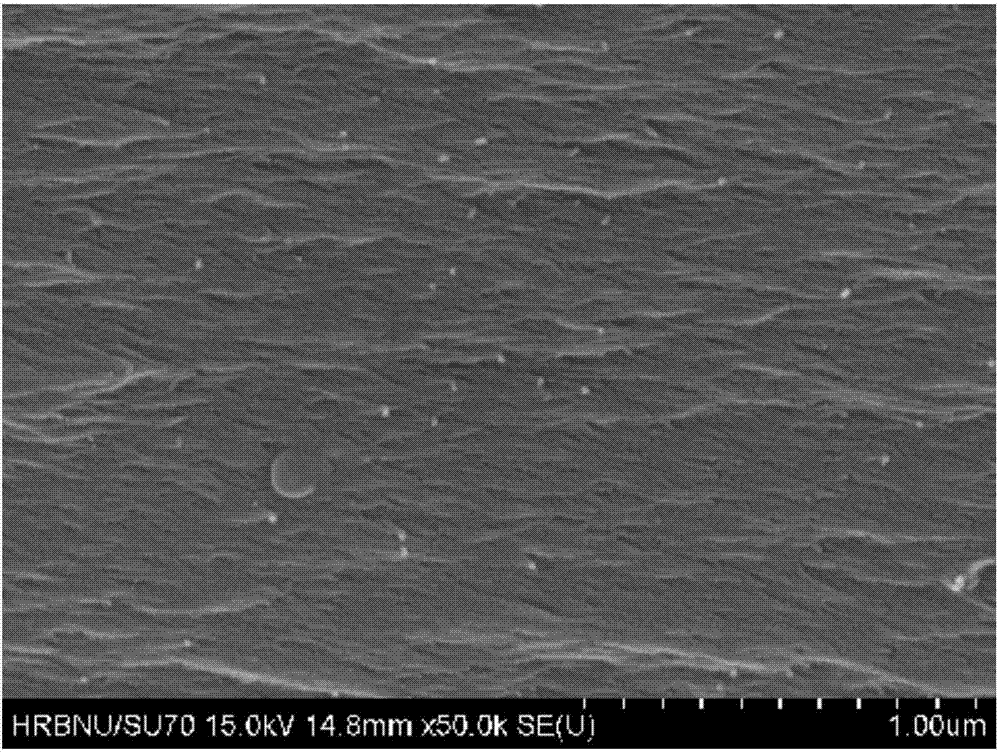

[0038] Embodiment 1: This embodiment is a method for preparing a polyimide composite film with high thermal conductivity and high insulation co-doped with boron nitride and aluminum nitride, which is characterized in that the method is completed according to the following steps:

[0039] 1. Preparation of ultra-thin boron nitride powder:

[0040] ①. Add boron nitride powder and oxides to concentrated acid, then stir and react in an ice-water bath at a stirring speed of 100r / min to 300r / min for 60min to 120min to obtain mixture A; heat mixture A to 50°C, Stir the reaction at a temperature of 50°C and a stirring speed of 100r / min to 300r / min for 60min to 180min, then cool to room temperature, and then add 30% hydrogen peroxide dropwise into mixture A at a rate of 1mL / min. solution to obtain mixture B; in an ice-water bath, add deionized water to mixture B to obtain mixture C; then centrifuge mixture C at a centrifugal speed of 6000r / min to 8000r / min for 5min to 15min, remove the...

specific Embodiment approach 2

[0062] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the organic solvent described in Step 2 ① is N-methylpyrrolidone or N-dimethylformamide. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0063] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the diamine in Step 2② is 4,4′-diaminodiphenyl ether. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com