Preparation method of oil-resistant non-slip sole

An anti-slip and oil-resistant technology, which is applied in the field of preparation of oil-resistant anti-slip soles, can solve the problems affecting quality, poor oil resistance and anti-slip performance, and poor mechanical properties, so as to prolong the service life, good anti-aging performance, and good mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

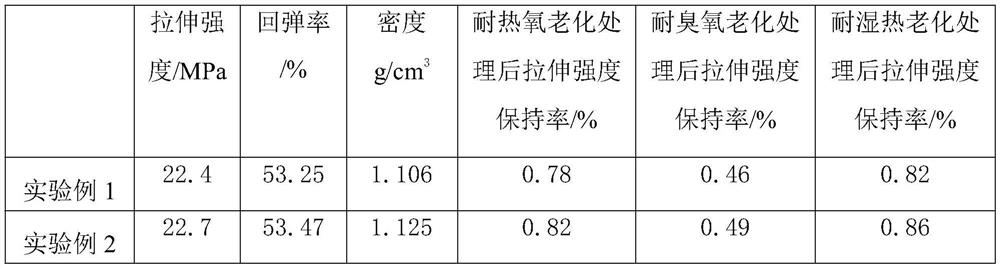

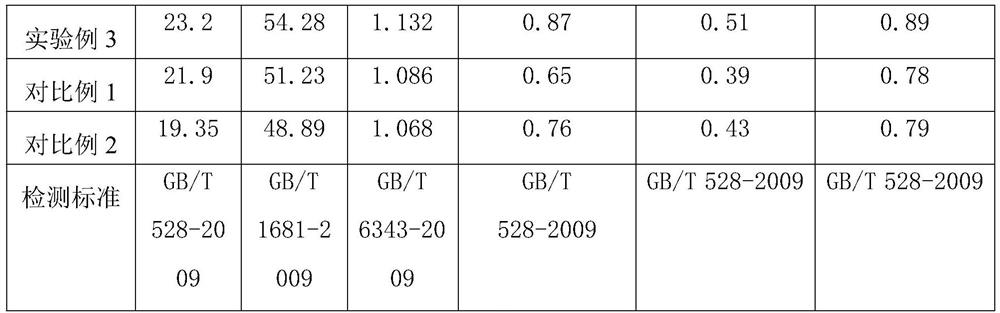

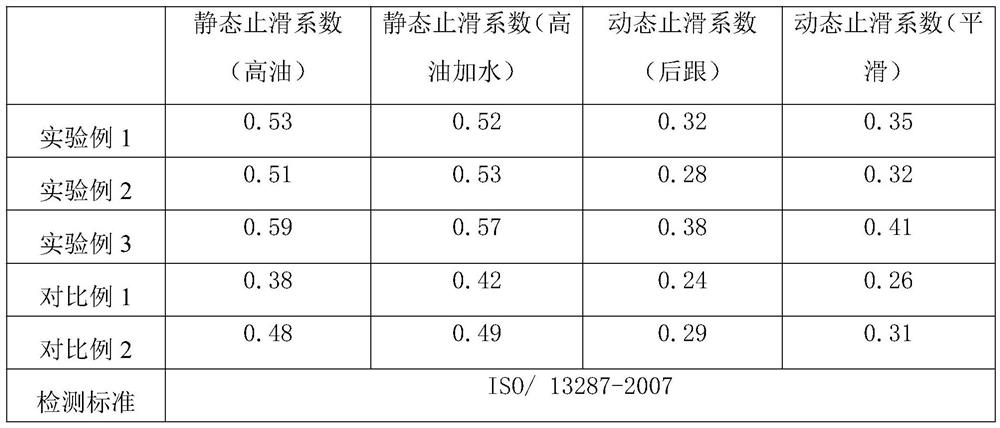

Examples

Embodiment 1

[0039] A preparation method for oil-resistant anti-slip soles, comprising the following steps:

[0040] S1. Accurately weigh 50 parts of nitrile rubber, 15 parts of butadiene rubber, 8 parts of epichlorohydrin rubber, 16 parts of white carbon black, 4 parts of DOPT oil, 3 parts of zinc oxide, and 10 parts of modified halloysite micropowder by weight. 1.8 parts of diethylene glycol, 2.4 parts of stearic acid, 3.2 parts of plasticizer, 1.5 parts of wear-resistant oil, 2.4 parts of vulcanizing agent and 2.0 parts of vulcanization accelerator; save and reserve;

[0041] S2. Put the nitrile rubber, butadiene rubber and epichlorohydrin rubber in the internal mixer for internal mixing, then transfer the rubber material after internal mixing to the open mixer for plasticizing, and then plasticize until the rubber is mixed The molecular chain is opened, and it is used as the main glue after being placed at room temperature for 24 hours;

[0042] S3. Add the remaining raw materials exc...

Embodiment 2

[0056] The preparation process of the oil-resistant non-slip sole is similar to that of Example 1, except that the proportioning ratio of the raw materials used is different; specifically: 55 parts of nitrile rubber, 18 parts of butadiene rubber, 10 parts of epichlorohydrin rubber, and 20 parts of white carbon black , 5 parts of DOPT oil, 4 parts of zinc oxide, 12 parts of modified halloysite powder, 2.0 parts of diethylene glycol, 3.0 parts of stearic acid, 4.0 parts of plasticizer, 1.8 parts of wear-resistant oil, 3.0 parts of vulcanizing agent and vulcanization Accelerator 2.5 parts;

[0057] And the weight ratio of modified halloysite powder semi-finished product, 1-amino-4-allyloxyanthraquinone, ethyl acetate and 2-hydroxy-2-methyl-1-phenylacetone is 1:0.2:5:0.04 ;

Embodiment 3

[0059] The preparation process of the oil-resistant non-slip sole is similar to that of Example 1, except that the proportioning ratio of the raw materials used is different; specifically: 60 parts of nitrile rubber, 20 parts of butadiene rubber, 13 parts of epichlorohydrin rubber, and 22 parts of white carbon black , 7 parts of DOPT oil, 6 parts of zinc oxide, 15 parts of modified halloysite powder, 2.5 parts of diethylene glycol, 3.8 parts of stearic acid, 4.5 parts of plasticizer, 2.0 parts of wear-resistant oil, 4.0 parts of vulcanizing agent and vulcanization Accelerator 3.5 parts;

[0060] And the weight ratio of the semi-finished halloysite powder, 1-amino-4-allyloxyanthraquinone, ethyl acetate and 2-hydroxy-2-methyl-1-phenylacetone is 1:0.24:7:0.045 ;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com