Cross-linked polymer composite material with isolation filler network structure and preparation method of cross-linked polymer composite material

A technology of cross-linked polymer and network structure, applied in the field of cross-linked polymer composite material and its preparation, cross-linked polymer composite material with isolated filler network structure and its preparation field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

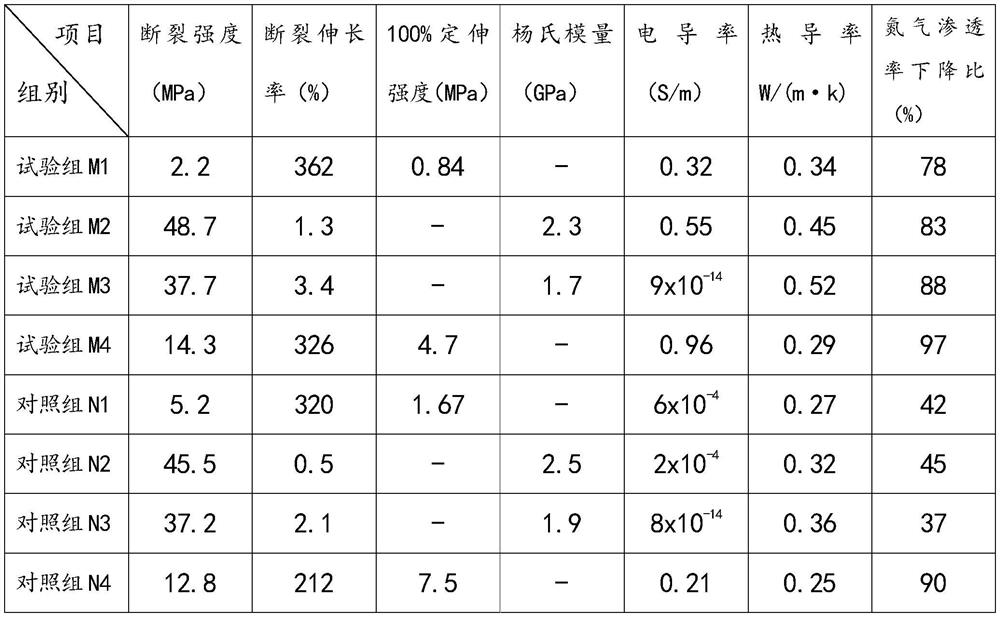

Examples

Embodiment 1

[0021] Example 1 A preparation method of cross-linked polymer composite material A1 with isolated network

[0022] This example provides a preparation method of a cross-linked polymer composite material A1 with an isolated network, the preparation method is the following steps carried out in sequence: Weigh 3 g of 2,2'-(1,4-phenylene)-bis [4-Mercapto-1,3,2-dioxaborane] (abbreviated as BDB) and 100g of styrene-butadiene rubber (specification: SBR2506) were put into the open mill, after blending for 20min, hot pressing at 160°C Curing to obtain the cross-linked styrene-butadiene rubber with borate ester bonds, which is then pulverized through an 80 mesh sieve;

[0023] Weigh 100g of cross-linked styrene-butadiene rubber particles with borate ester bonds and 1g of carbon nanotubes, mix them for 2 minutes under a high-speed mixer (20000r / min), and then mold them at 160°C and 20MPa for 30 minutes to obtain a composite material with an isolated network. Cross-linked polymer composi...

Embodiment 2

[0024] Example 2 A preparation method of cross-linked polymer composite material A2 with isolated network

[0025] This embodiment 2 provides a kind of preparation method of cross-linked polymer composite material A2 with isolation network, this preparation method is to take 200g bisphenol A, 100g glutaric anhydride, 10g transesterification reaction catalyst zinc acetate and stir and mix evenly, Then solidify 12 hours at 140 DEG C again, obtain the epoxy resin that 300g contains β-hydroxyl ester bond, then it is pulverized into particle and crosses 150 mesh sieves;

[0026] Disperse 300g of epoxy resin particles in 150mL of ethanol, disperse 0.6g of graphene in 500mL of ethanol, stir and mix the above two solutions, ultrasonic for 1 hour, and then volatilize ethanol at 60°C to obtain graphene-coated epoxy Resin particles were then hot-pressed at 180° C. under a pressure of 10 MPa for 45 minutes to obtain a cross-linked polymer composite material A2 with an isolated network.

Embodiment 3

[0027] Embodiment 3 A kind of preparation method of cross-linked polymer composite material A3 with isolated network

[0028] This embodiment 3 provides a preparation method of a cross-linked polymer composite material A3 with an isolated network. The preparation method is to weigh 134g of terephthalaldehyde, 30.9g of diethylenetriamine and 68.14g of triethylenetetra Stir and mix the amine evenly, pour it into a mold and place it at 80°C and 120°C to cure for 1 hour to obtain 200g of polyimide resin containing imine bonds, and then crush it into particles and pass through a 120-mesh sieve;

[0029] Disperse 100g of polyimide resin particles in 100mL of ethanol, ultrasonically disperse 2.5g of boron nitride in 250mL of ethanol, then stir and mix the above two solutions, and then volatilize the ethanol at 60°C to obtain boron nitride-coated poly The imine resin particles were then hot-pressed at 150° C. under a pressure of 10 MPa for 30 minutes to obtain a cross-linked polymer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com