Method for functional modification of carbon nanotubes (CNTs) applicable to composite rubber system

A technology of carbon nanotubes and composite rubber, which is applied in the field of material science, can solve problems such as difficult dispersion and uniformity, and achieve the effect of safe and simple raw materials, convenient operation, and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

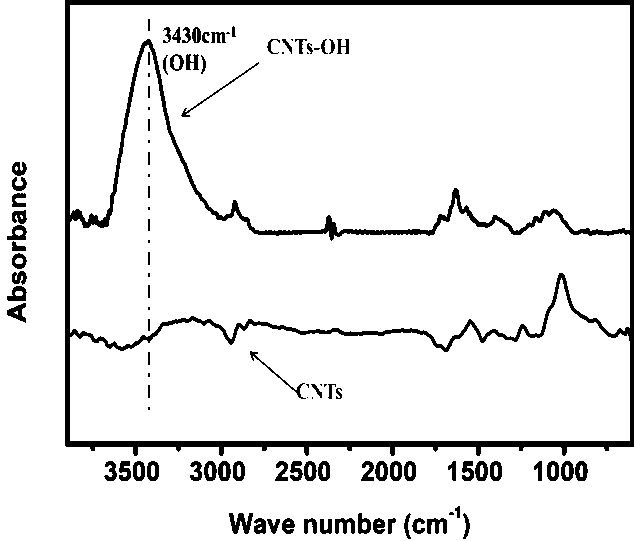

[0031] The method for functionally modifying CNTs comprises the following steps.

[0032] (1) Disperse 2.0g CNTs in 200ml: 200ml of H 2 o 2 and H 2 O mixed solution. Sonicate for 1 hour in a water bath at 80 °C.

[0033] (2) The above treated CNTs were washed several times with distilled water, and dried in a vacuum oven at 50° C. for 48 hours to obtain hydroxylated CNTs.

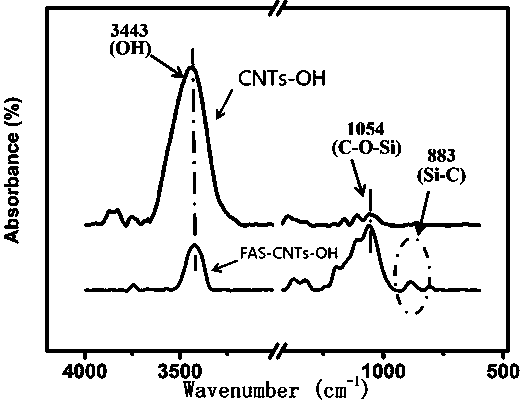

[0034] (3) Prepare an AC-FAS ethanol solution with a volume fraction of 1.8%, and mix rapidly within the temperature range of 20°C-25°C. The pH of the solution was then adjusted to 3.5 with glacial acetic acid.

[0035] (4) Add the hydroxylated CNTs prepared in step (2) to the AC-FAS ethanol solution prepared in step (3), configure a mixed solution with a solute mass fraction of 1.7%, and mix and stir magnetically for 2 hours at 40°C. Then the modified CNTs were separated from the supernatant by filtration and washed at least 5 times with ethanol. After washing, they were dried in a vacuum oven at 60...

Embodiment 2

[0037] The method for functionally modifying CNTs comprises the following steps.

[0038] (1) Disperse 2.0g CNTs in 200ml: 200ml of H 2 o 2 and H 2 O mixed solution. Sonicate for 1 hour in a water bath at 80 °C.

[0039] (2) The above treated CNTs were washed several times with distilled water, and dried in a vacuum oven at 60° C. for 48 hours to obtain hydroxylated CNTs.

[0040] (3) Prepare an AC-FAS ethanol solution with a volume fraction of 3.2%, and mix rapidly within the temperature range of 20°C-25°C. The pH of the solution was then adjusted to 3.5 with glacial acetic acid.

[0041] (4) Add the hydroxylated CNTs prepared in step (2) to the AC-FAS ethanol solution prepared in step (3), configure a mixed solution with a solute mass fraction of 1.7%, and mix and stir magnetically for 2 hours at 40°C. Then the modified CNTs were separated from the supernatant by filtration and washed at least 5 times with ethanol. After washing, they were dried in a vacuum oven at 60...

Embodiment 3

[0043] The method for functionally modifying CNTs comprises the following steps.

[0044] (1) Disperse 2.0g CNTs in 200ml: 200ml of H 2 o 2 and H 2 O mixed solution. Sonicate for 1 hour in a water bath at 80 °C.

[0045] (2) The above treated CNTs were washed several times with distilled water, and dried in a vacuum oven at 60° C. for 48 hours to obtain hydroxylated CNTs.

[0046] (3) Prepare an AC-FAS ethanol solution with a volume fraction of 4.7%, and mix rapidly within the temperature range of 20°C-25°C. The pH of the solution was then adjusted to 3.5 with glacial acetic acid.

[0047] (4) Add the hydroxylated CNTs prepared in step (2) to the AC-FAS ethanol solution prepared in step (3), configure a mixed solution with a solute mass fraction of 1.7%, and mix and stir magnetically for 2 hours at 40°C. Then the modified CNTs were separated from the supernatant by filtration and washed at least 5 times with ethanol. After washing, they were dried in a vacuum oven at 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com