Patents

Literature

40results about How to "Solve Application Bottlenecks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Functional nano-composite material, preparation method and application thereof

ActiveCN106694055APayloadAvoid low loadMicroorganismsOrganic-compounds/hydrides/coordination-complexes catalystsNanoparticleEngineering

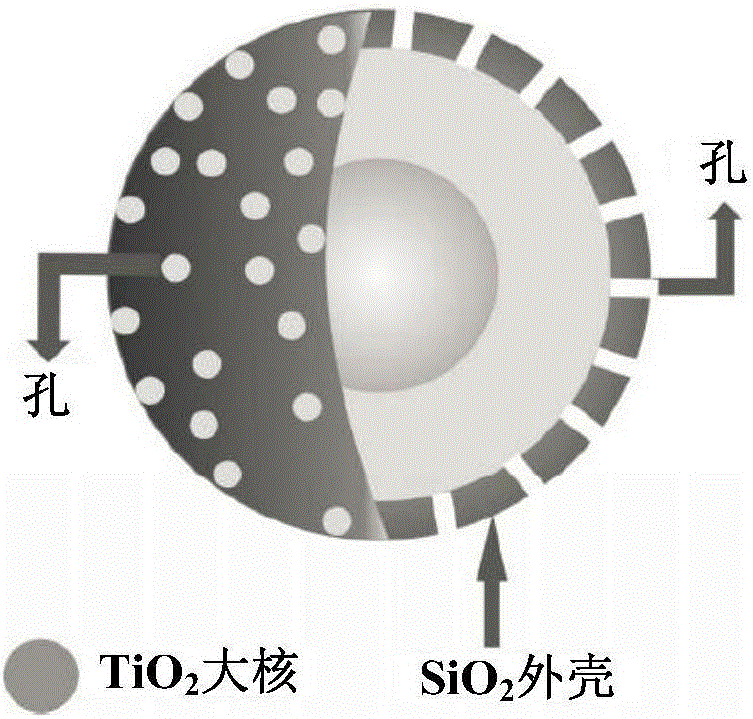

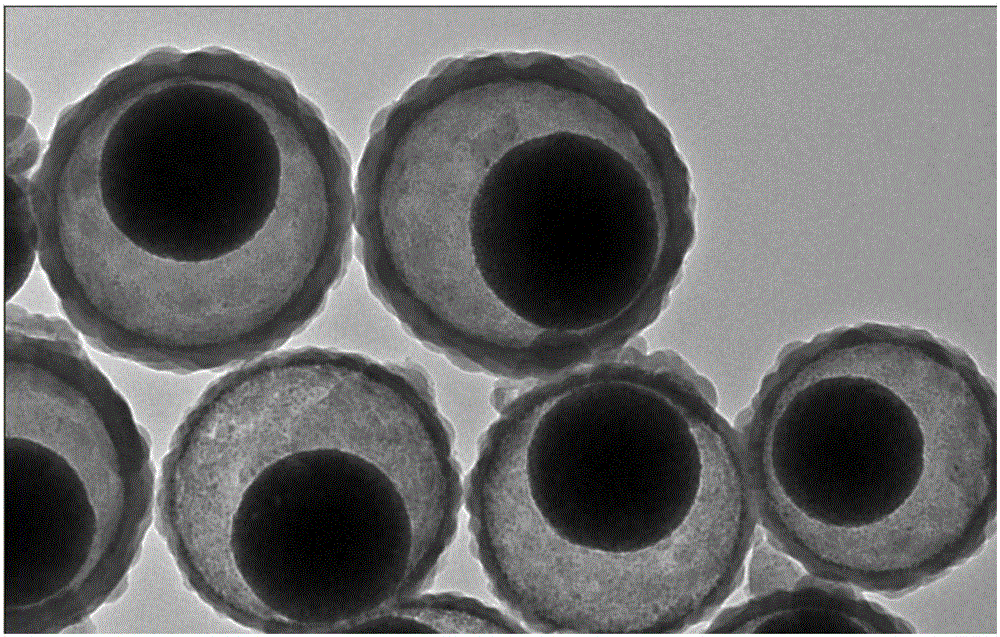

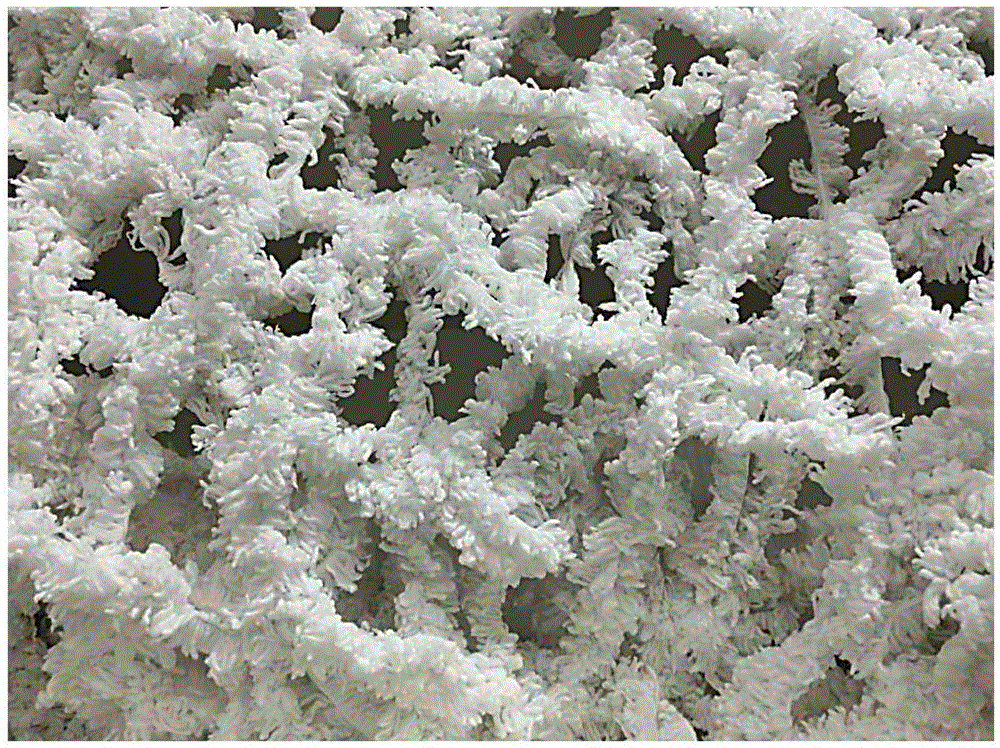

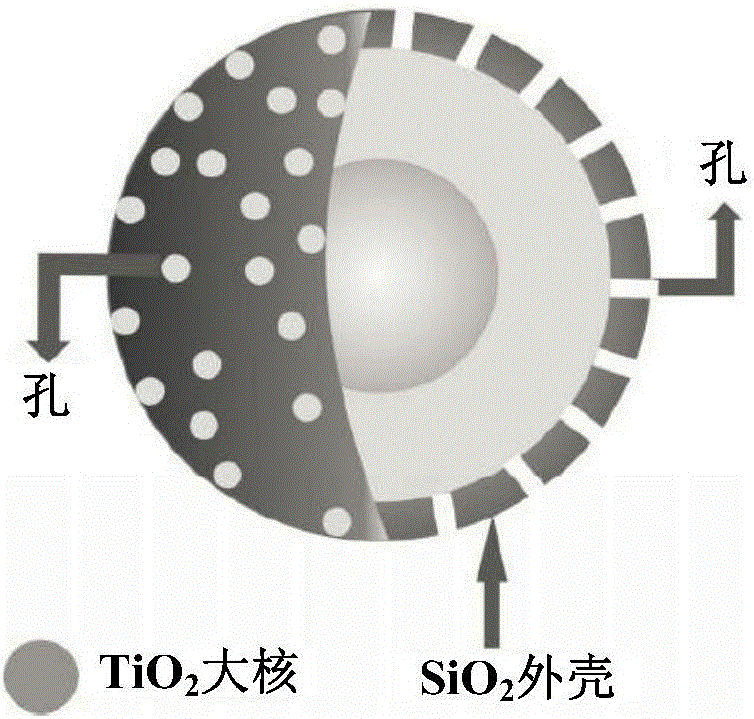

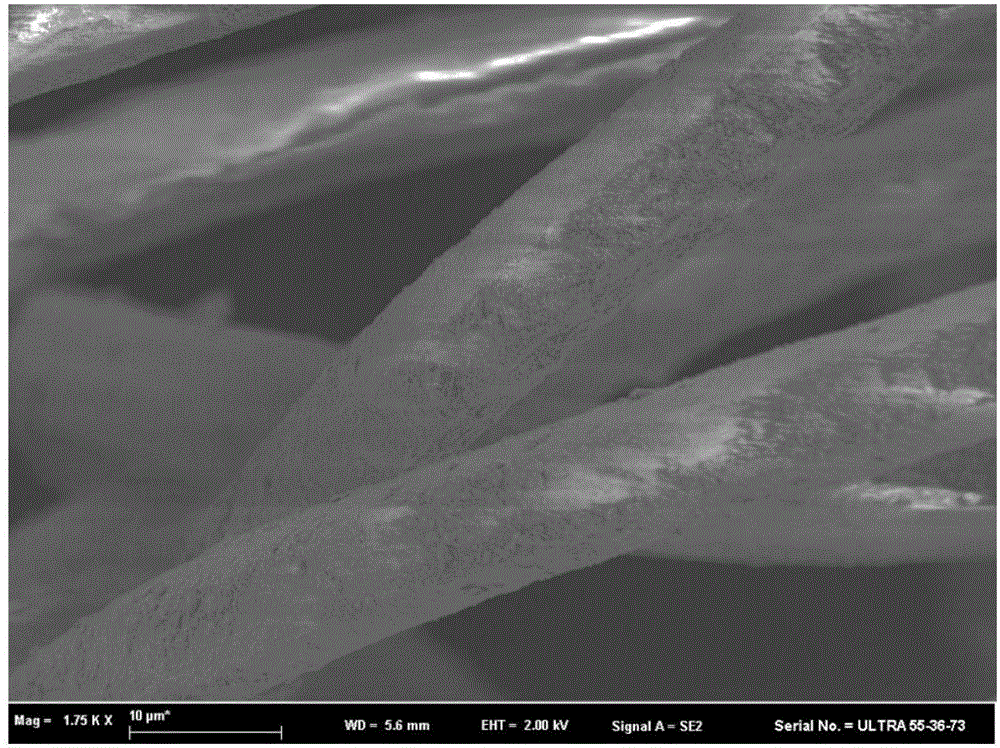

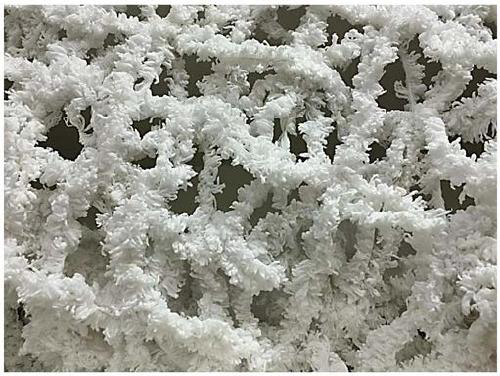

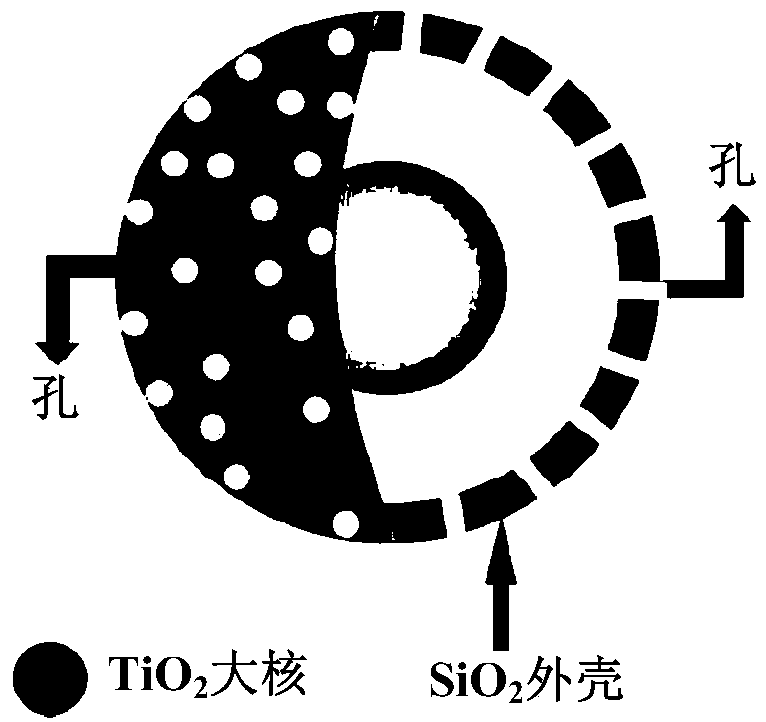

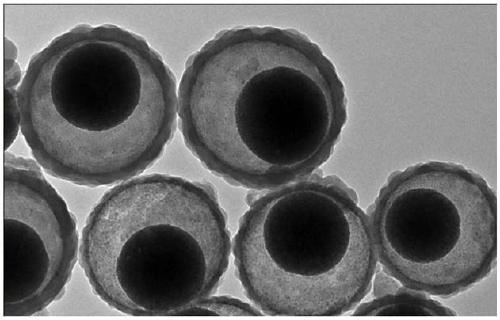

The invention provides a functional nano-composite material, which comprises a flexible fiber carrier and a plurality of functional nanoparticles immobilized in the flexible fiber carrier. The flexible fiber carrier comprises at least one brush-like structure, and the plurality of functional nanoparticles are clamped and fixed in the at least one brush-like structure. The invention also provides a preparation method and application of the functional nano-composite material. In the invention, flexible fiber is adopted as the carrier to realize effective loading of the functional nanoparticles. The loading compounding mode can realize high capacity loading of the functional nanoparticles, and the loading rate is up to 10% of the weight of the flexible fiber carrier. At the same time, the functional nanoparticles can be extended to all scenes in which the flexible fiber carrier can be applied, can be applied to sewage purification, air purification, bacteria resistance, disinfection and other environmental protection fields, and the application range is very wide.

Owner:鲸果科技(杭州)有限公司

Nano-composite fiber material and preparation method thereof

InactiveCN106592005APayloadAvoid low loadWater/sewage treatment by irradiationWater treatment compoundsFiberOrganic solvent

The invention provides a preparation method of a nano-composite fiber material. The preparation method includes the steps of (1), dispersing multiple functional nanoparticles into an organic solvent so as to form functional nanoparticle suspension; (2), providing a fusion-state organic polymer carrier material; (3), spraying the functional nanoparticle suspension on the fusion-state organic polymer carrier material so as to enable the functional nanoparticles to be attached to the surface of the fusion-state organic polymer carrier material; (4), curing a fusion-state organic polymer carrier material obtained from the step (3) so as to obtain the nano-composite fiber material. The invention further provides the nano-composite fiber material prepared by the preparation method. The nano-composite fiber material has the advantages that the functional nanoparticles can be effectively loaded on the organic polymer carrier material, so that high-capacity functional nanoparticle load can be achieved; the nano-composite fiber material can be applied to the environment-friendly fields of wastewater purification, air purification, bacterium resistance, disinfection and the like.

Owner:嘉兴迈之新材料科技有限公司

Composite fiber material as well as preparation method and application thereof

The invention provides a composite fiber material. The composite fiber material comprises an organic fiber carrier and a plurality of functional nanoparticles embedded into the organic fiber carrier. The invention further provides a preparation method of the composite fiber material. The preparation method comprises the following steps: (1) heating the plurality of functional nanoparticles; (2) jetting the plurality of heated functional nanoparticles onto the organic fiber carrier through hot air flow, and melting contact parts of the organic fiber carrier and the plurality of functional nanoparticles so as to embed the plurality of functional nanoparticles into the organic fiber carrier. The composite fiber material takes the organic fiber carrier as a carrier so as to effectively load the functional nanoparticles. In the loading compounding way, the high loading capacity of the functional nanoparticles can be achieved. Meanwhile, the functional nanoparticles are expanded to all scenes to which a flexible fiber carrier can be applied. The composite fiber material can be applied to the fields of sewage purifying treatment, air purifying treatment or antibacterial sterilizing treatment or the like.

Owner:HANGZHOU TONG KING ENVIRONMENT TECH CO LTD

Metal-organic framework material, and molding method and application thereof

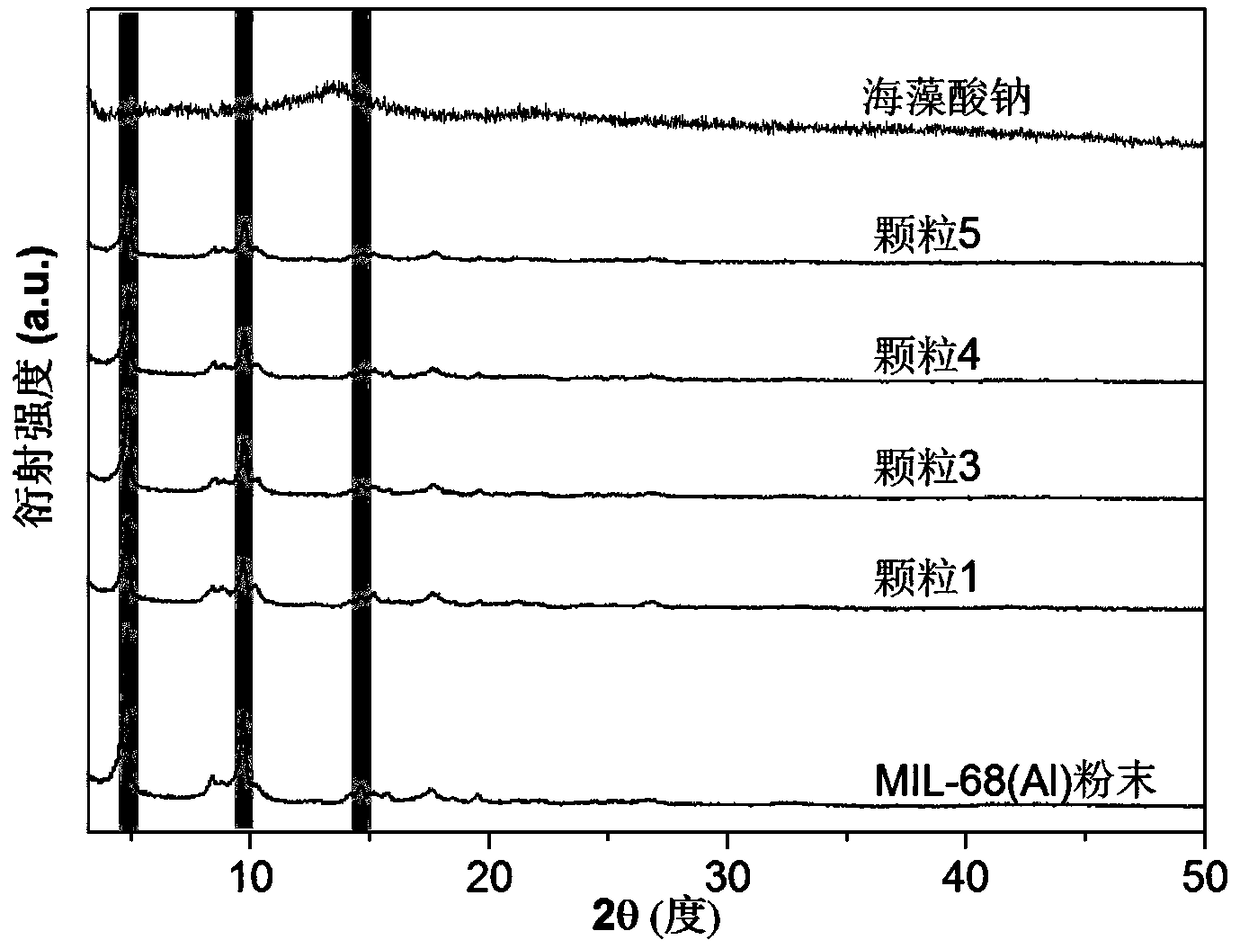

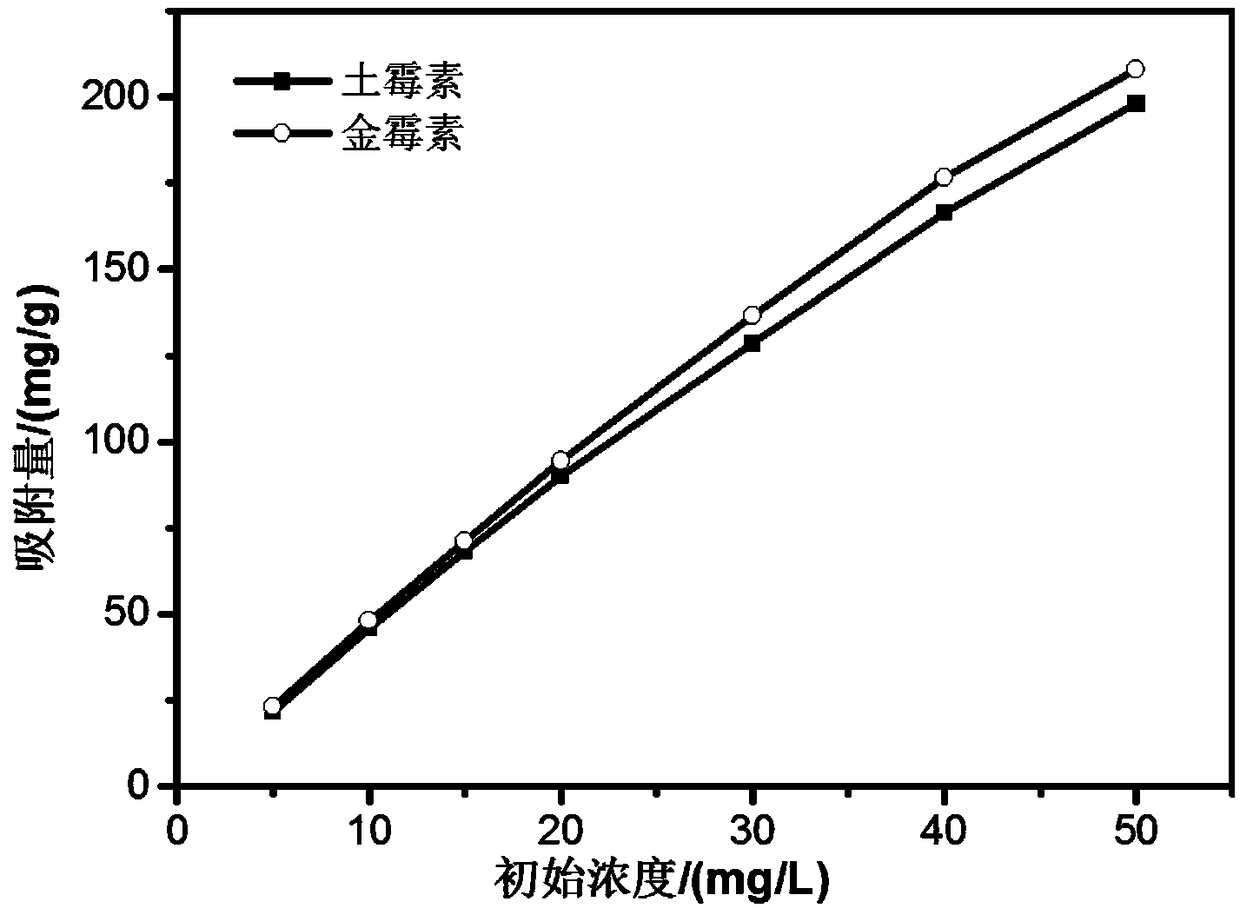

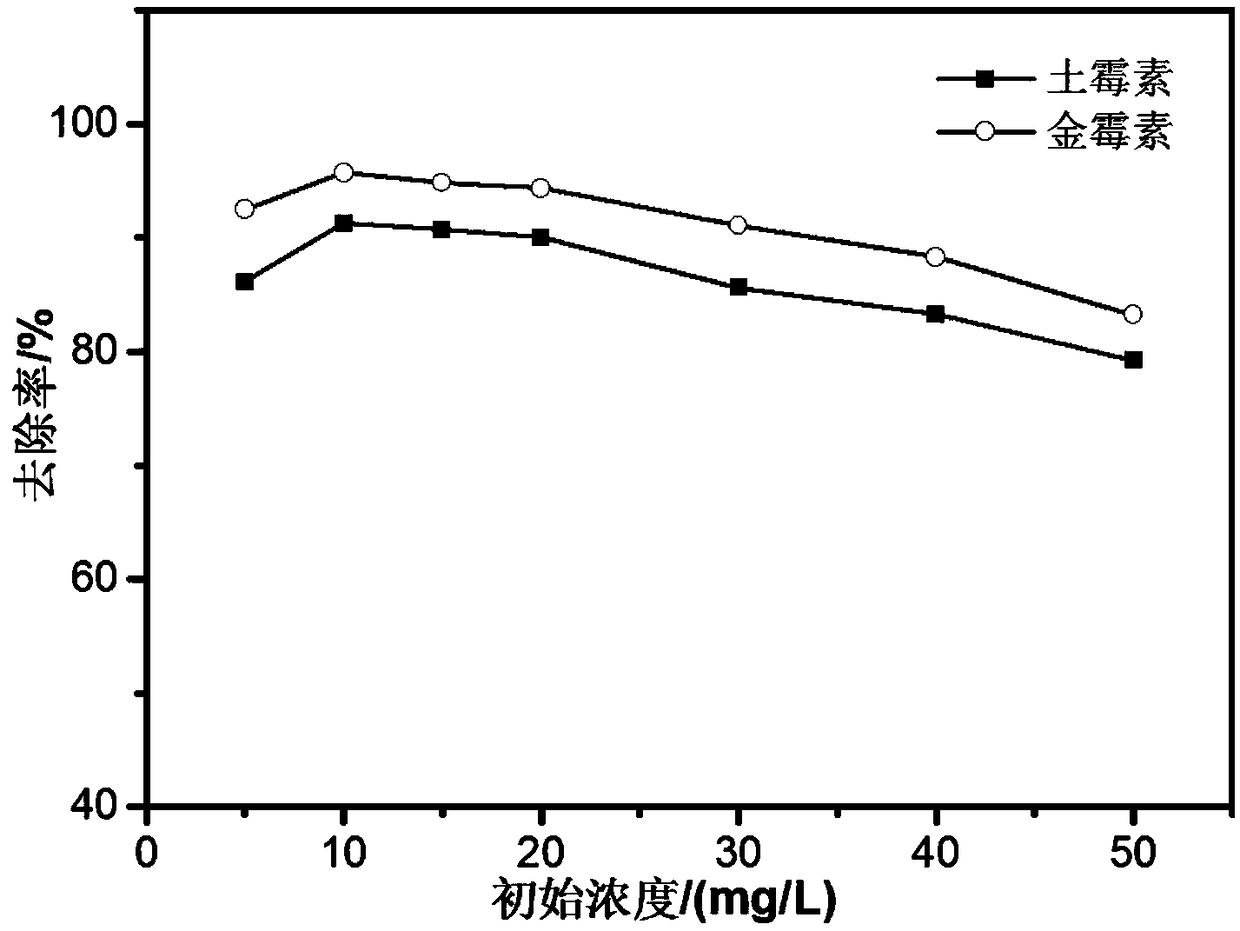

InactiveCN108940211AOvercoming easy loss and difficult recyclingEfficient removalOther chemical processesWater contaminantsScience and engineeringMetal-organic framework

The invention belongs to the technical field of environmental science and engineering, and discloses a metal-organic framework material and a molding method thereof, and an application in the field ofwastewater treatment and organic matter adsorption. The molding method includes the following steps: (1) adding a metal-organic framework material into water to prepare into a matrix solution, and adding sodium alginate to perform heating and uniform mixing so that a colloidal liquid can be obtained; and (2) adding the colloidal liquid into a calcium chloride solution, and performing standing, filtering, washing and drying so that metal-organic framework material particles can be obtained. The metal-organic framework material obtained by the method is also provided. The method can effectivelyshape the powdery metal-organic framework material, and the obtained particle materials can keep the crystalline structure of an original metal-organic framework; and the molded material particles effectively overcomes the technical problems of easy loss and hard recycle of powder materials, technical effects of efficiently removing tetracycline antibiotics in water can be realized, and the metal-organic framework material can be applied to the field of treating wastewater and removing organic matters.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

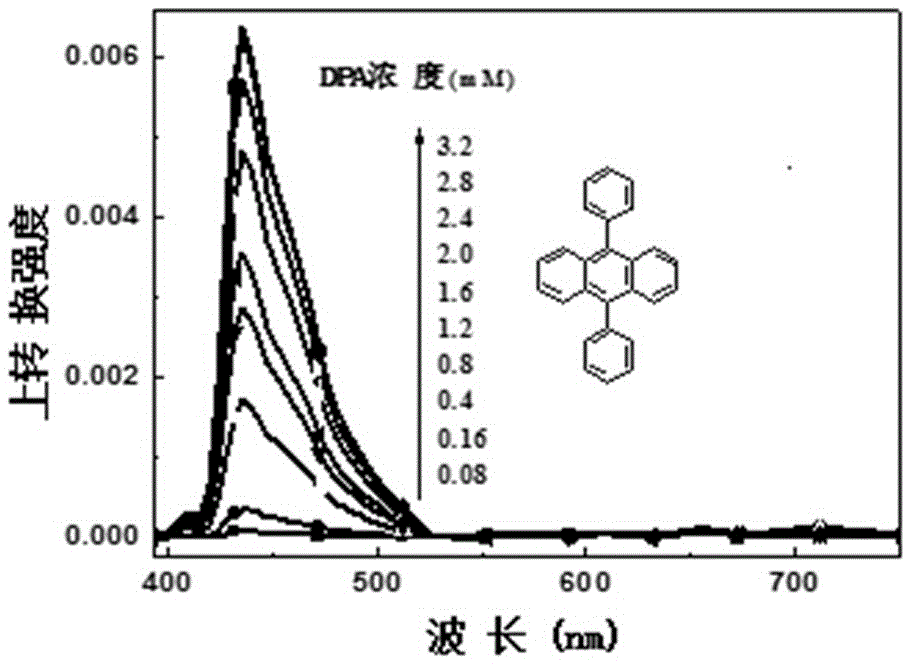

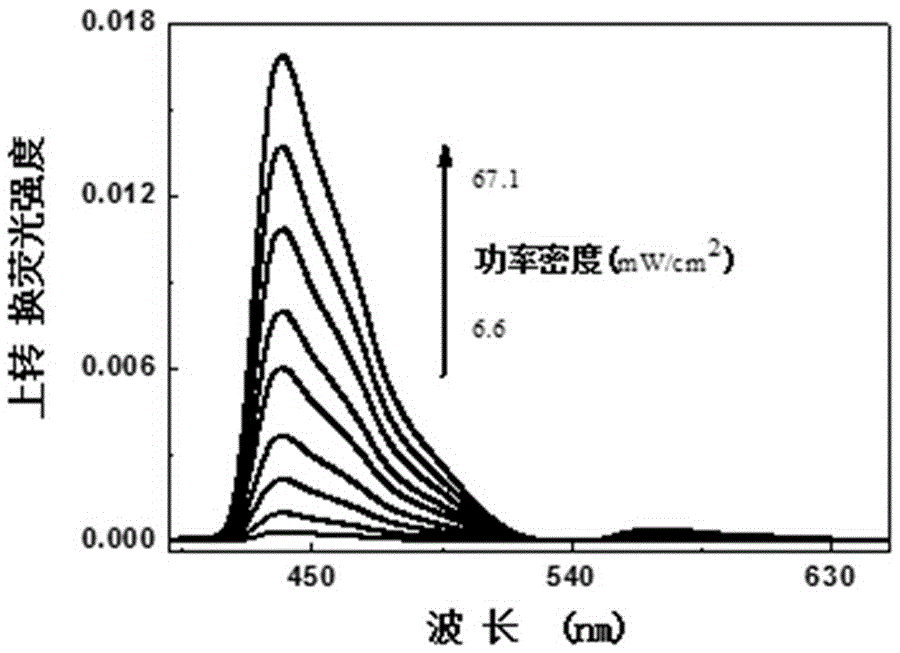

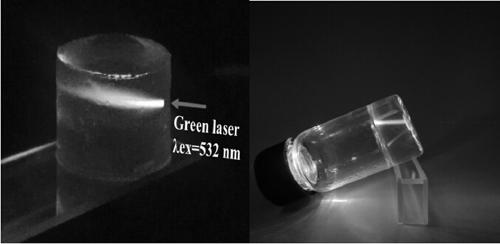

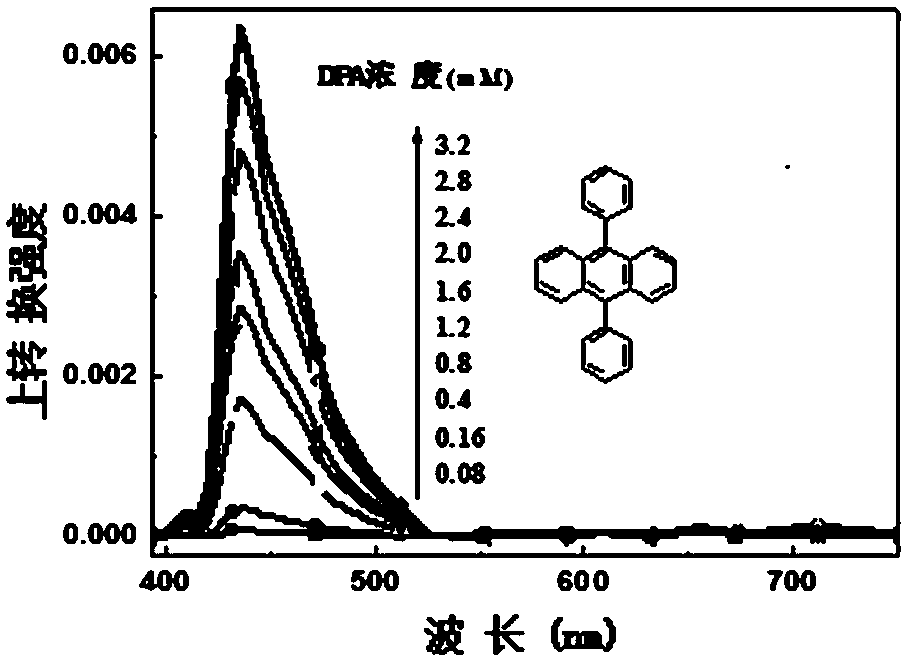

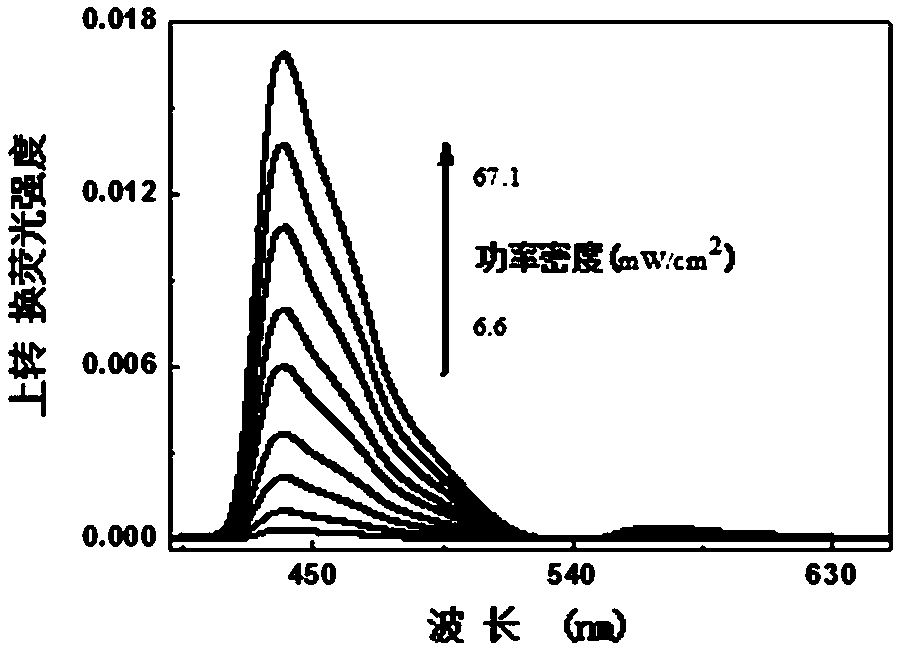

Upconversion resin with polydimethylsiloxane as matrix and preparation method and application thereof

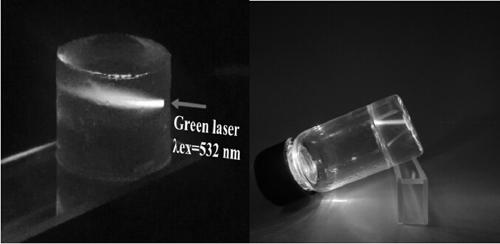

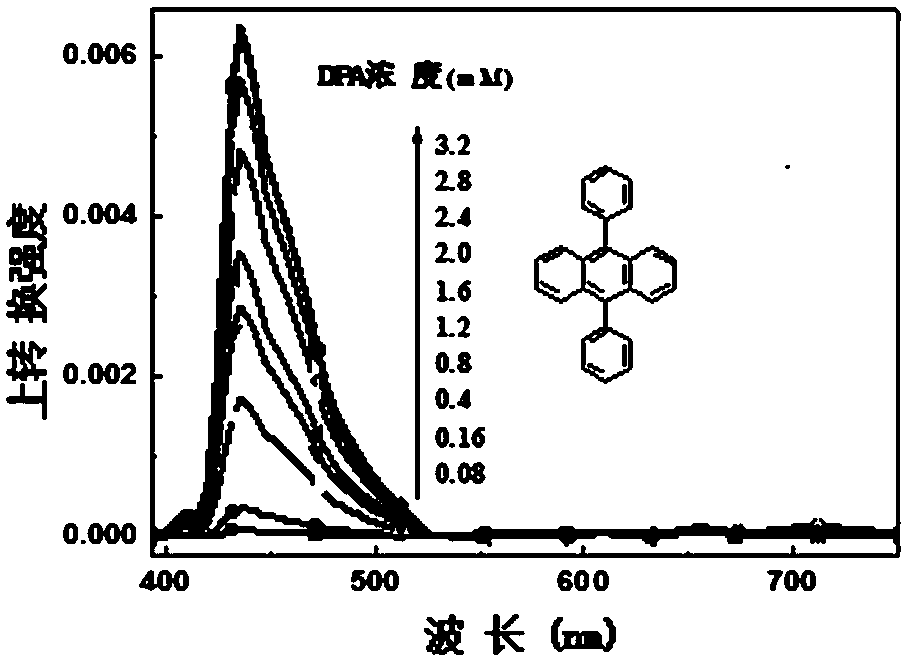

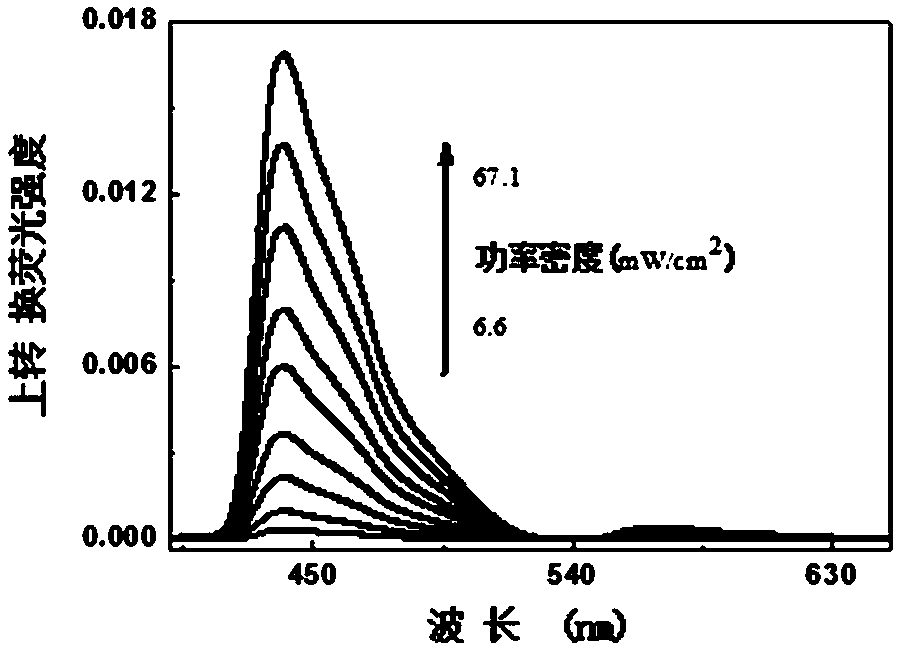

ActiveCN105647519ANo pollutant dischargeSimple preparation processOrganic chemistryElectrolysis componentsOrganosolvNitrogen atmosphere

The invention discloses upconversion resin with polydimethylsiloxane as a matrix and a preparation method and application thereof. In a nitrogen atmosphere, a silane crosslinking agent and dimethyl siloxane monomers are mixed according to the mass ratio of 1:(10-30); then heat preservation is conducted for 2 h at the temperature of 100 DEG C after vacuum treatment; then natural cooling is conducted, and polysiloxane is formed; then in the nitrogen atmosphere, polysiloxane is placed in an organic solvent containing a photosensitizer and an illuminating agent to be soaked for 18-30 h, polysiloxane is taken out and dried, and then a solid upconversion double-component system based on polysiloxane is obtained. The invention discloses the preparation method of the solid upconversion resin with PDMS as the matrix and green-to-blue light generated by the solid upconversion resin for the first time, the solution-state upconversion system is converted into a solid material, high upconversion efficiency is achieved, and potential application value is achieved on the aspects of hydrogen production through water photolysis and photosynthesis.

Owner:SUZHOU UNIV OF SCI & TECH

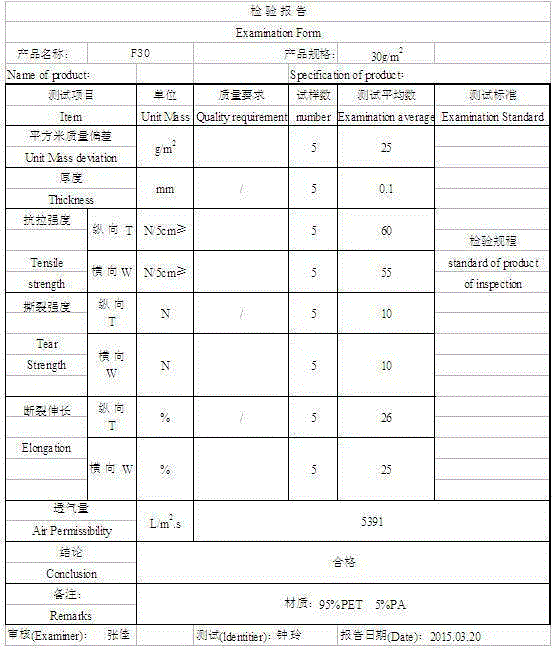

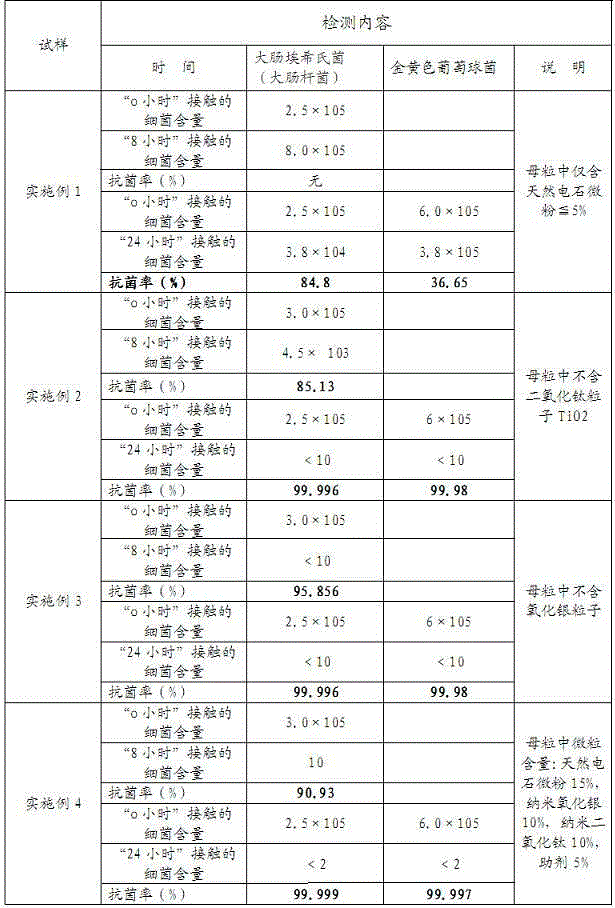

Novel efficient and low-resistance compound antibacterial air filtering material

ActiveCN105169813AImprove adsorption capacityImprove filtering effectSynthetic resin layered productsFiltration separationBiotechnologyPolyethylene terephthalate glycol

The invention discloses a novel efficient and low-resistance compound antibacterial air filtering material. The novel efficient and low-resistance compound antibacterial air filtering material comprises a PET / PA (Polyethylene Terephthalate / Polyamide) double-component filament fiber bottom layer and an antibacterial master batch / PP (Polypropylene) fiber surface layer, wherein the two layers are melt-blown and self-adhered by double nozzles; the tensile strength of fibers of the bottom layer is high and components of antibacterial master batches of the surface layer are special; the filtering material can be used for firmly adsorbing micro-particles, bacteria and viruses, which have negative charges, in a filtering material so that the bacteria and the viruses lose the activity and the sterilization effect is realized; and the 8-hour inhibition rate on colon bacillus and staphylococcus aureus is more than 99.5%.

Owner:宿迁市美达净化科技有限公司

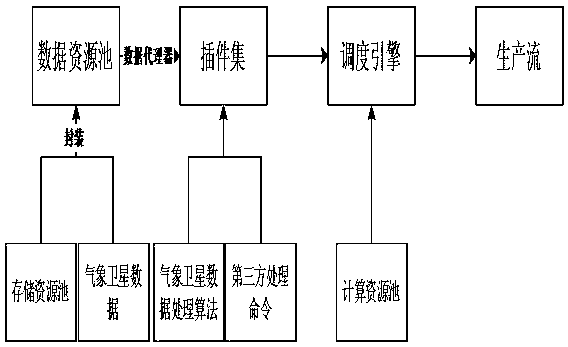

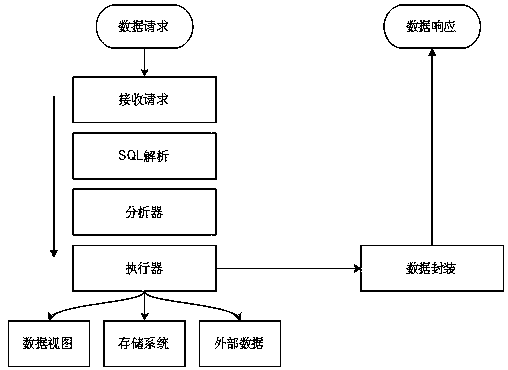

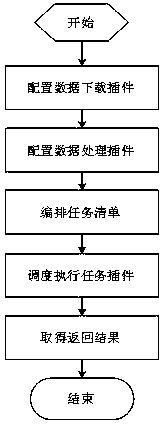

Cloud computing and data virtualization-based weather satellite data processing system

ActiveCN108255539ASolve Application BottlenecksSolve the space-time consistency problemDatabase management systemsResource allocationResource poolData processing system

The invention discloses a cloud computing and data virtualization-based weather satellite data processing system. A proposed data resource pool solves the problems of massive satellite data storage and computation, and solves the problems of massive satellite data storage and time-space coherence of satellite data storage; a time-space attribute is a most basic attribute of weather satellite dataand also a most complex attribute of the weather satellite data, and is a difficult point of a storage scheme; in storage system and scheme design, the time-space attribute of a satellite can be constructed and identified through a file name, a key, a file directory, an URI and the like in a unified environment; the satellite data can be subjected to virtualization operations of extraction, reconstruction, mapping and the like according to a time-space scale of storage and application; rich data views are provided; and based on the data views, the system can finish complex weather satellite data computing and processing. Therefore, the great convenience is brought for application of the weather satellite data.

Owner:华风象辑(北京)气象科技有限公司

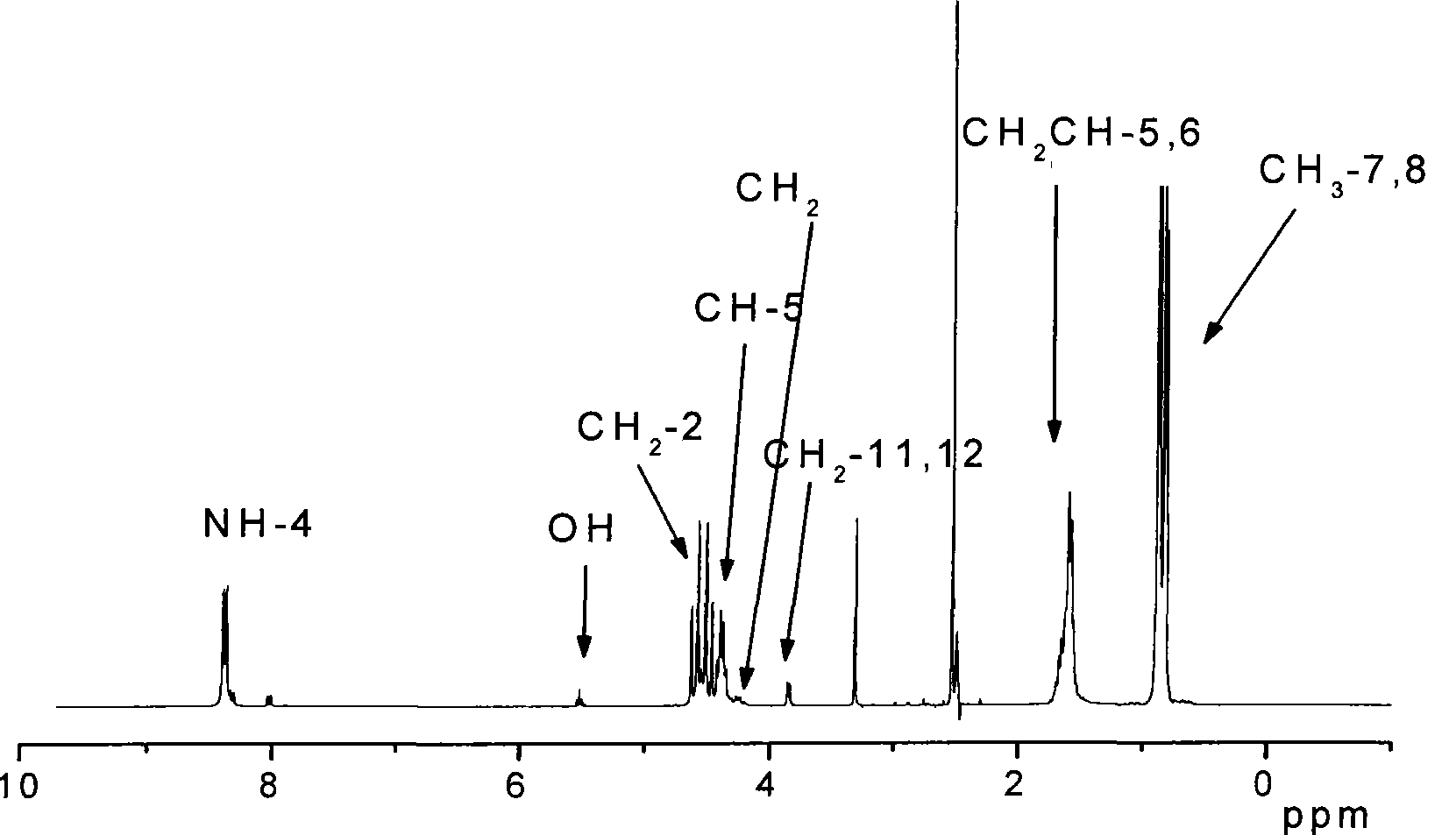

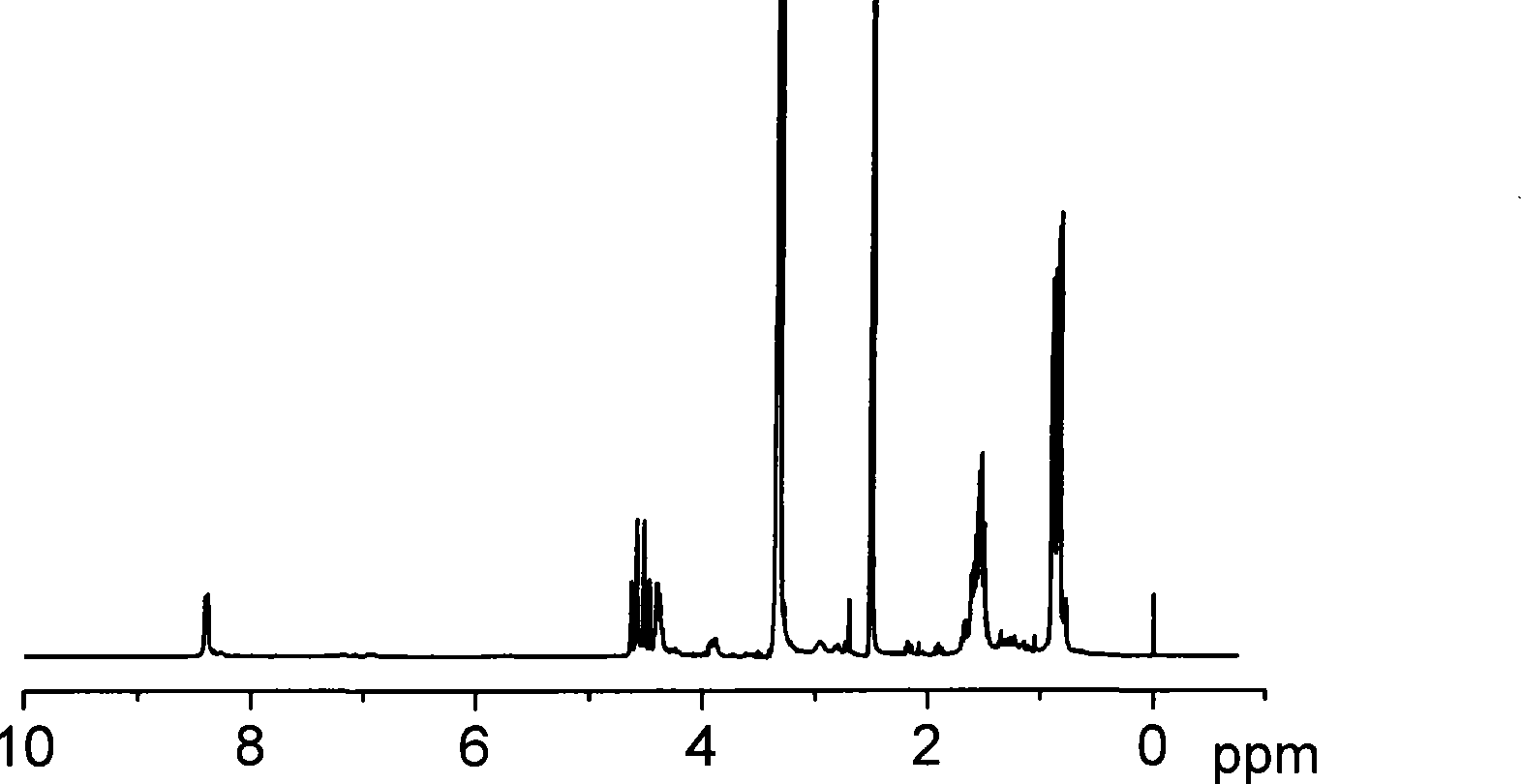

Preparation method of high molecular weight poly-morpholine-2,5-dione derivative and preparation method of the copolymer thereof

The invention discloses a preparation method of a high molecular weight poly-morpholine-2,5-dione derivative and a preparation method of the copolymer thereof. The preparation method of the high molecular weight poly-morpholine-2,5-dione derivative comprises the following steps: (1) morpholine-2,5-dione derivative, organic tin catalyst and dihydric alcohol are weighted and mixed to react to obtain the dihydroxy-terminal poly-morpholine-2,5-dione derivative after separation and purification; and (2) the dihydroxy-terminal poly-morpholine-2,5-dione derivative is mixed with a chain extender in proportion to react under air-isolated conditions to obtain the high molecular weight poly-morpholine-2,5-dione derivative. The high molecular weight poly-morpholine-2,5-dione derivative and the copolymer thereof prepared by the preparation methods have high molecular weight, biodegradability and good mechanical properties owning to high molecular weight, thereby meeting the requirement of the application of high molecular materials for medical use.

Owner:TIANJIN UNIV

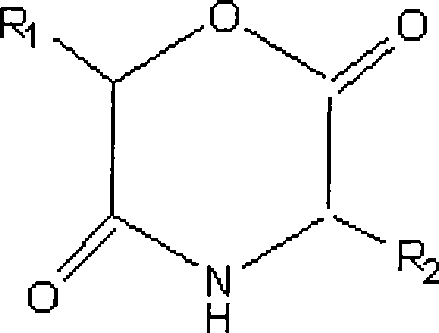

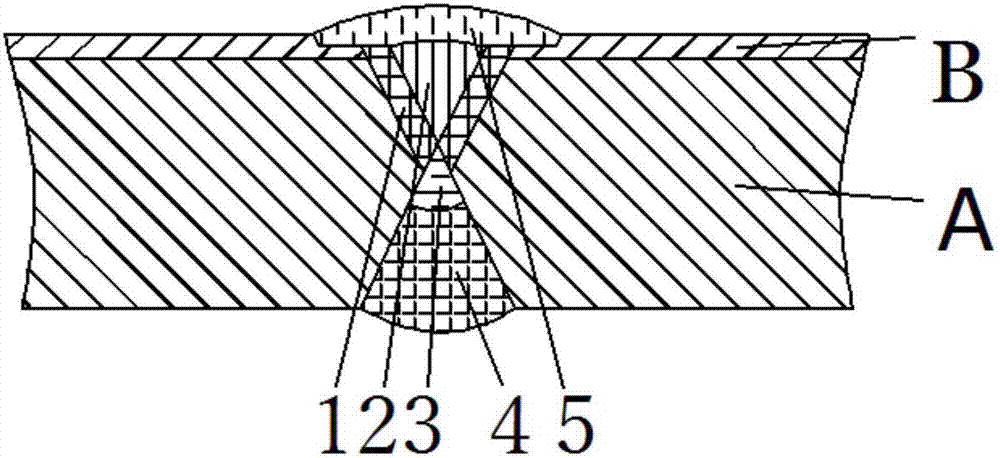

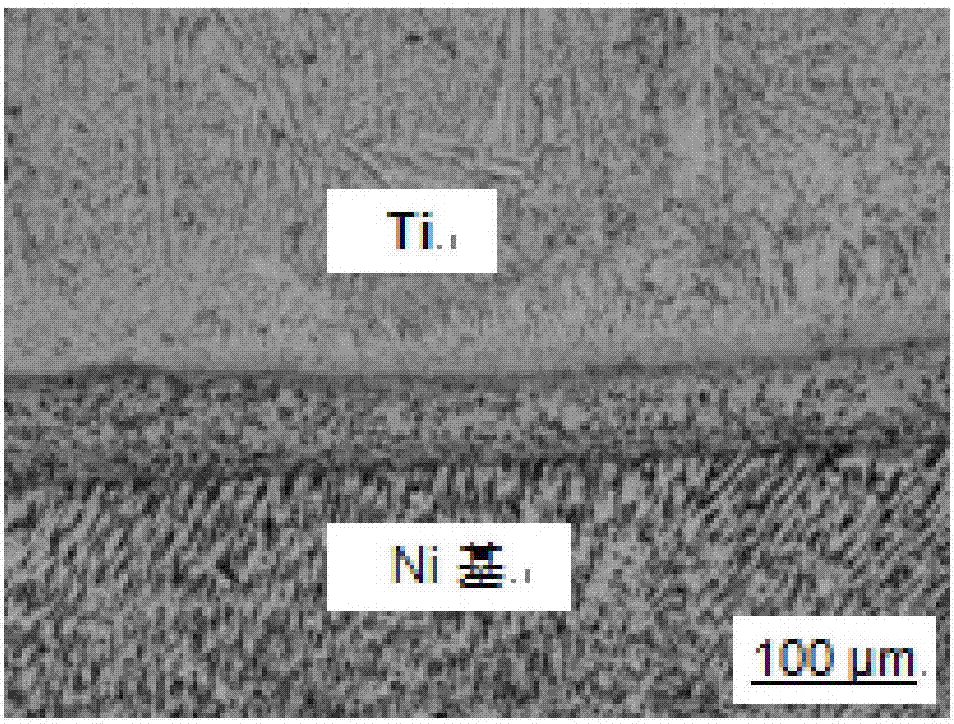

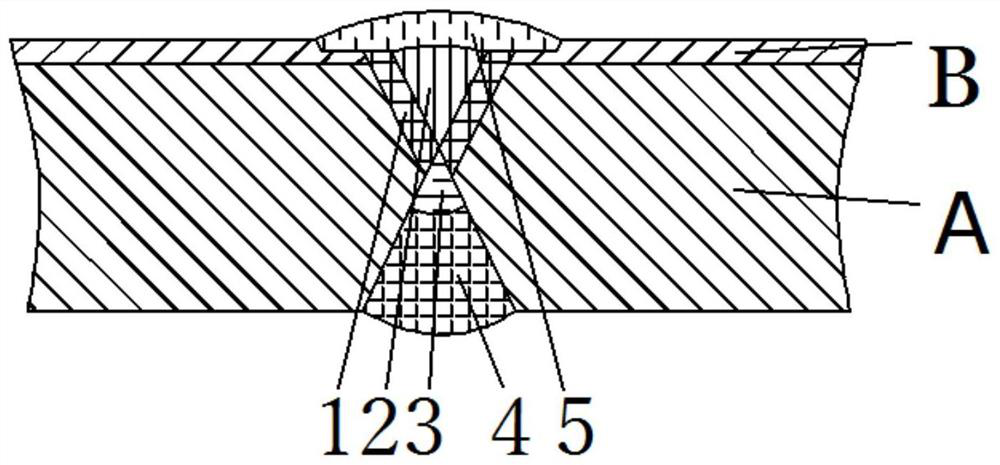

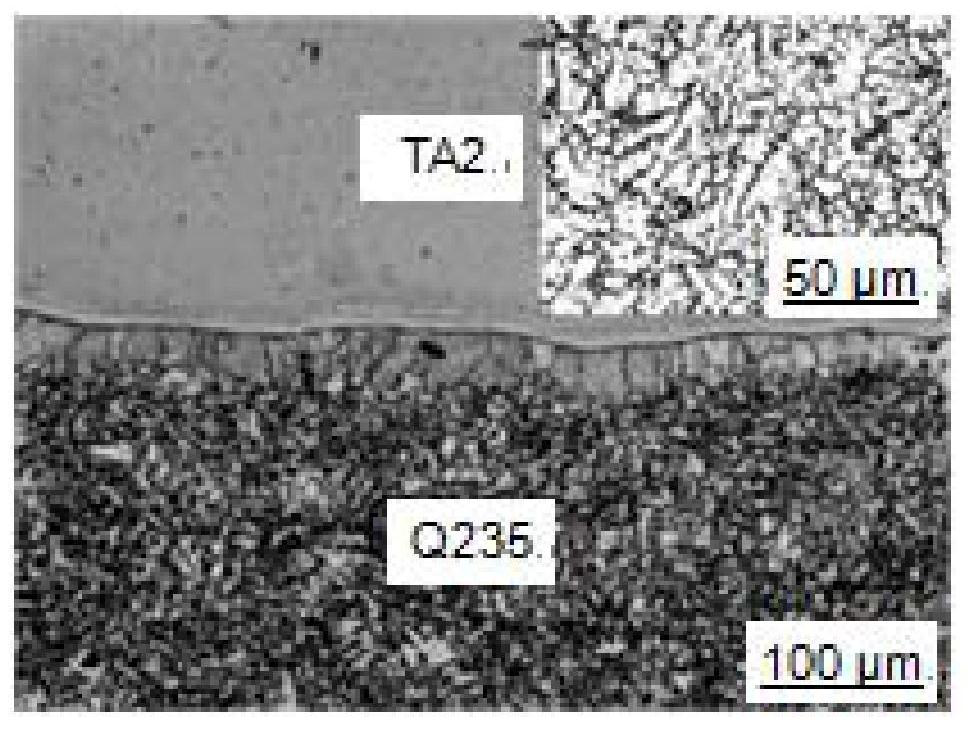

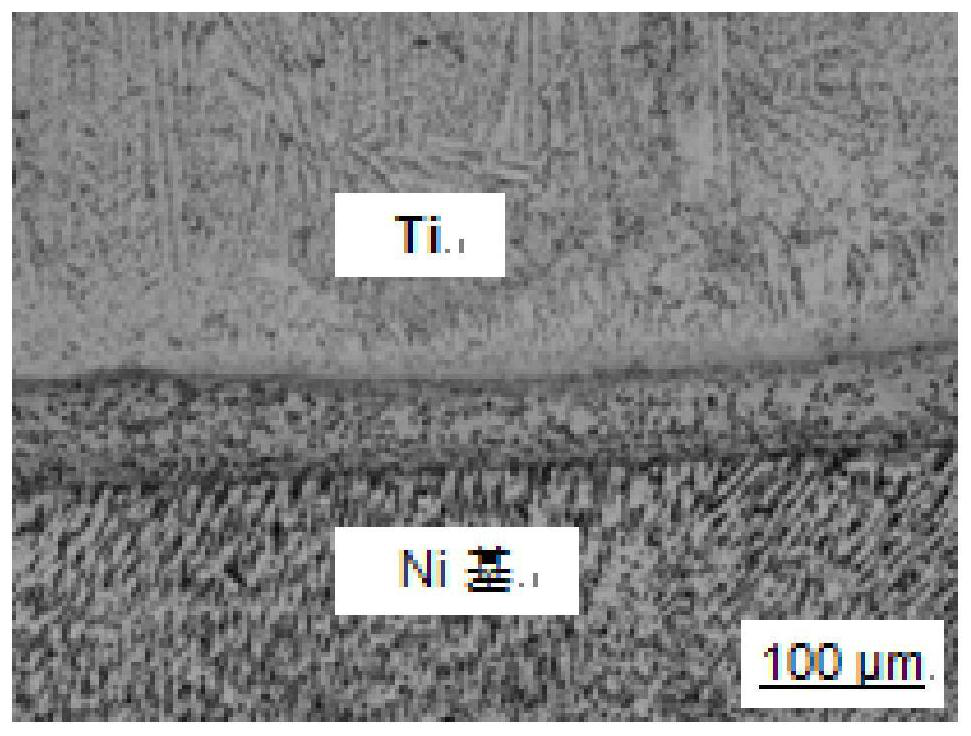

Welding materials for butt welding of transition layers of titanium clad steel plate and welding method of welding materials

ActiveCN107984054AImproves Strength and ToughnessSolve Application BottlenecksArc welding apparatusWelding/cutting media/materialsMetallic NickelButt joint

The invention discloses welding materials for butt welding of transition layers of a titanium clad steel plate and a welding method of the welding materials, and belongs to the technical field of metal material welding. The welding materials comprise a welding material for a surfacing layer and a near-titanium layer, a welding material for a bottoming layer, a welding material for a steel layer and a welding material for a titanium layer, wherein the welding material for the surfacing layer and the near-titanium layer comprises, by weight percentage, less than or equal to 0. 011% of carbon, less than or equal to 0.32% of silicon, 2.0-4.0% of manganese, less than or equal to 0.01% of phosphorus, less than or equal to 0.01% of sulfur, 10-17% of chromium, 2-16% of molybdenum, less than or equal to 2.0% of copper, less than or equal to 5.0% of ferrum and the balance nickel; and the welding material for the bottoming layer comprises more than or equal to 99.9% of nickel. The welding methodcomprises the following step that a groove form of a welding joint is designed to be an X-shaped groove, surfacing is carried out on the groove of the surfacing layer, then the near-titanium layer isfilled and welded with the near-welding material for the near-titanium layer, welding is carried out on the steel layer by using the welding material of ordinary carbon steel, and finally welding is carried out on the titanium layer by using an industrial TA2 welding wire. The welding materials and the welding method have the advantage that the fusion welding butt joint of the titanium clad steelplate has relatively high strength and toughness; and the problem of application bottleneck of welding of the titanium clad steel plate can be solved.

Owner:CENT IRON & STEEL RES INST

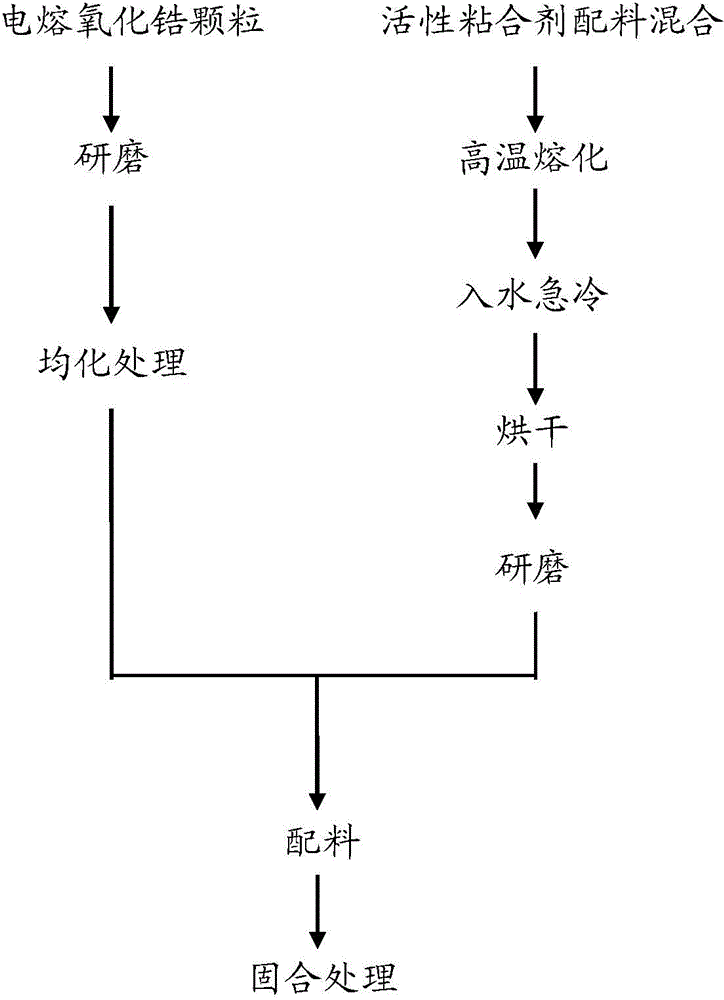

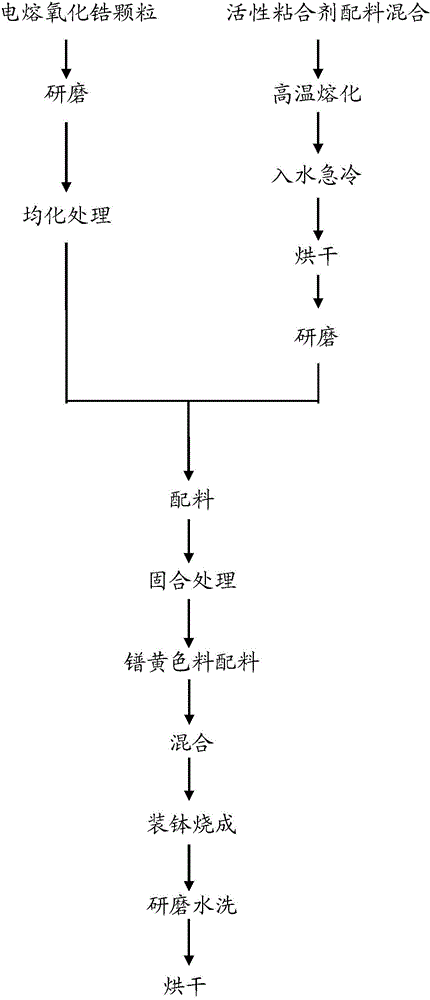

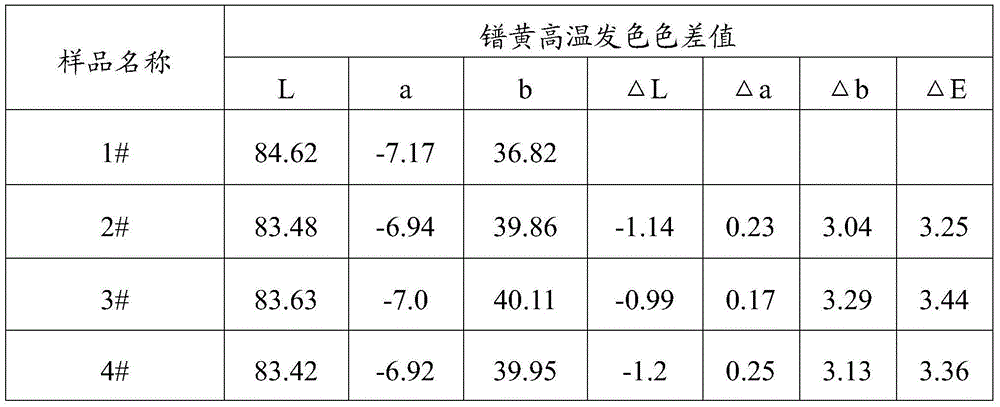

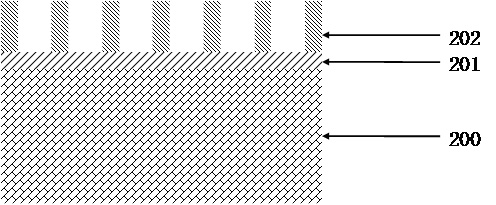

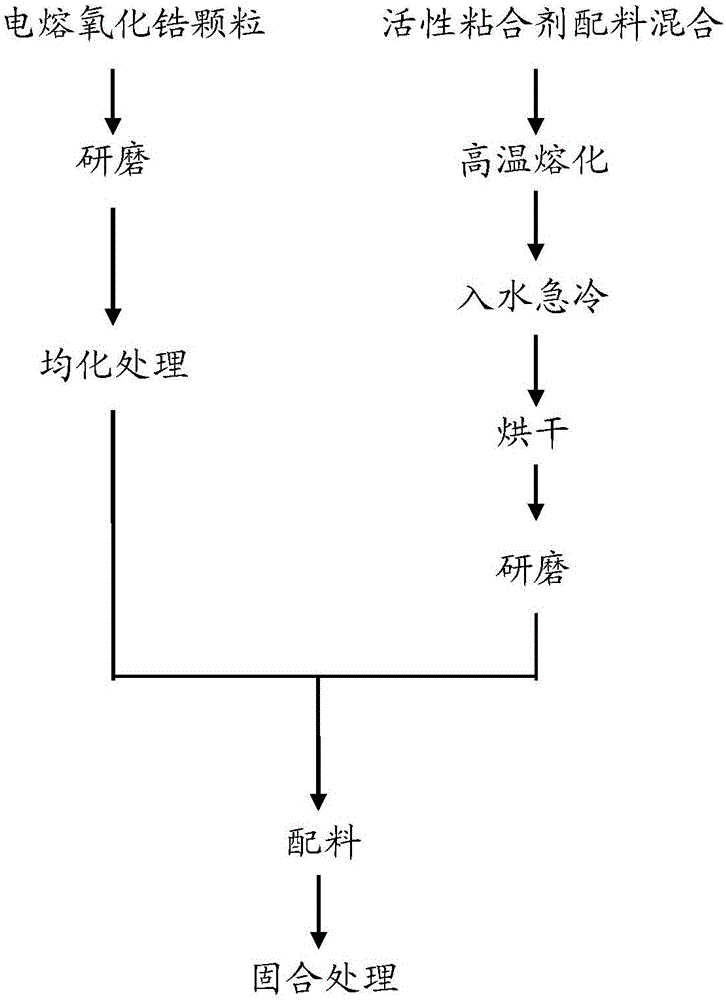

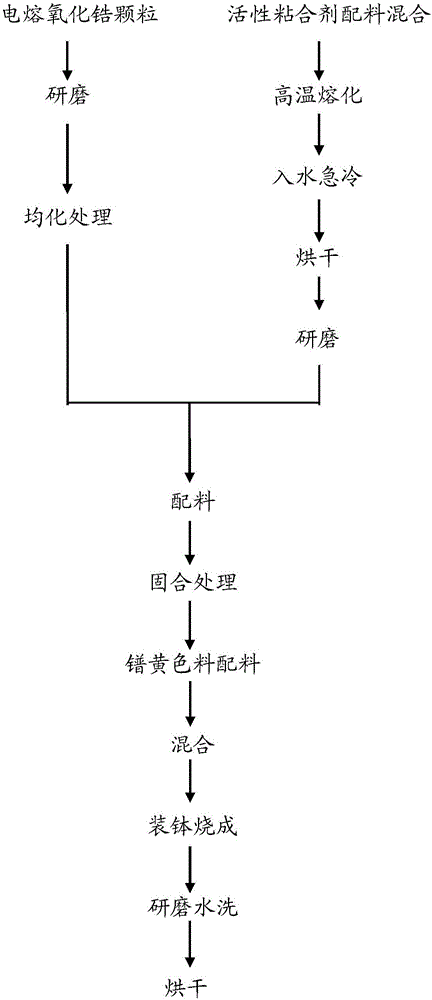

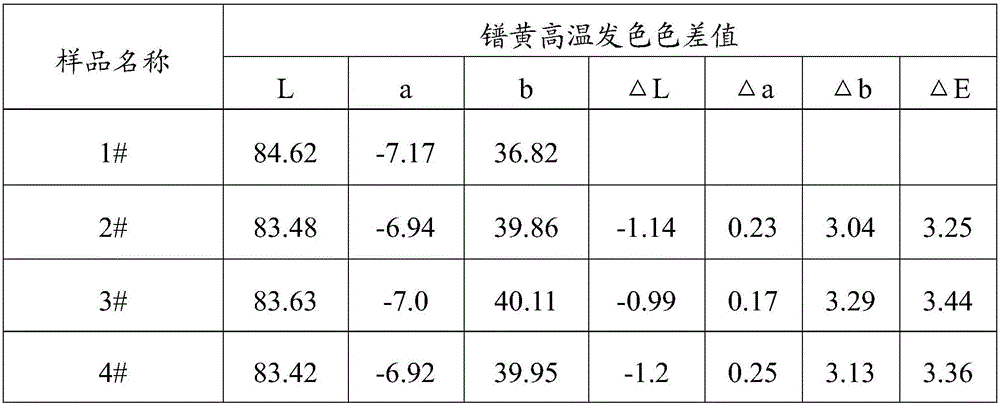

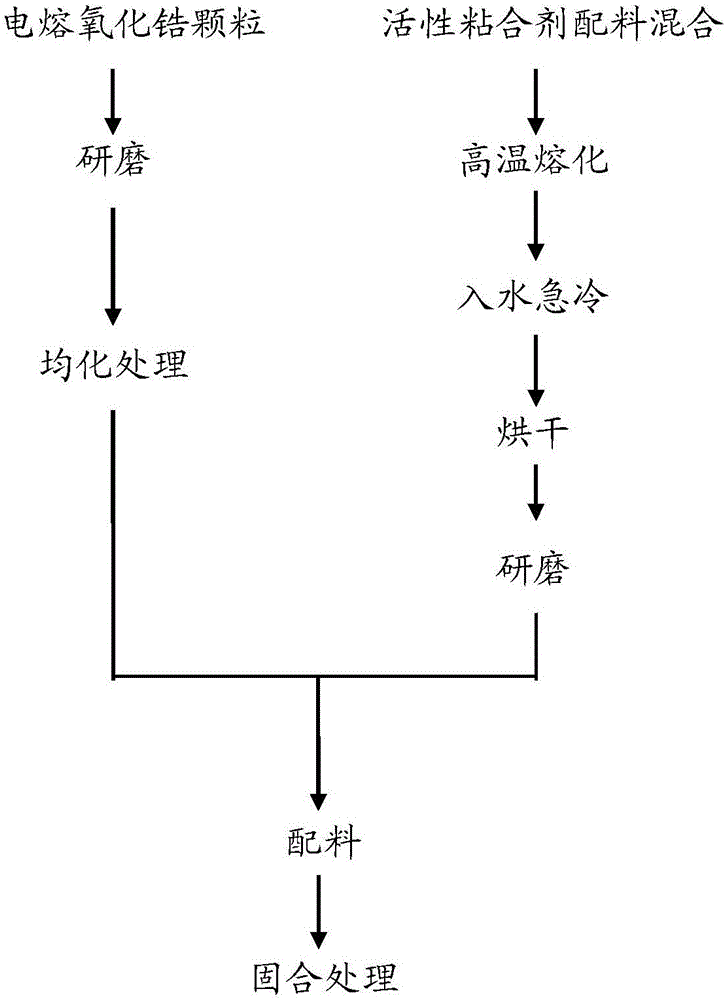

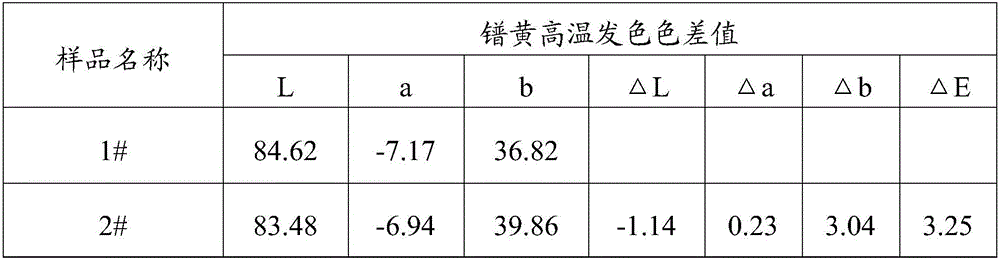

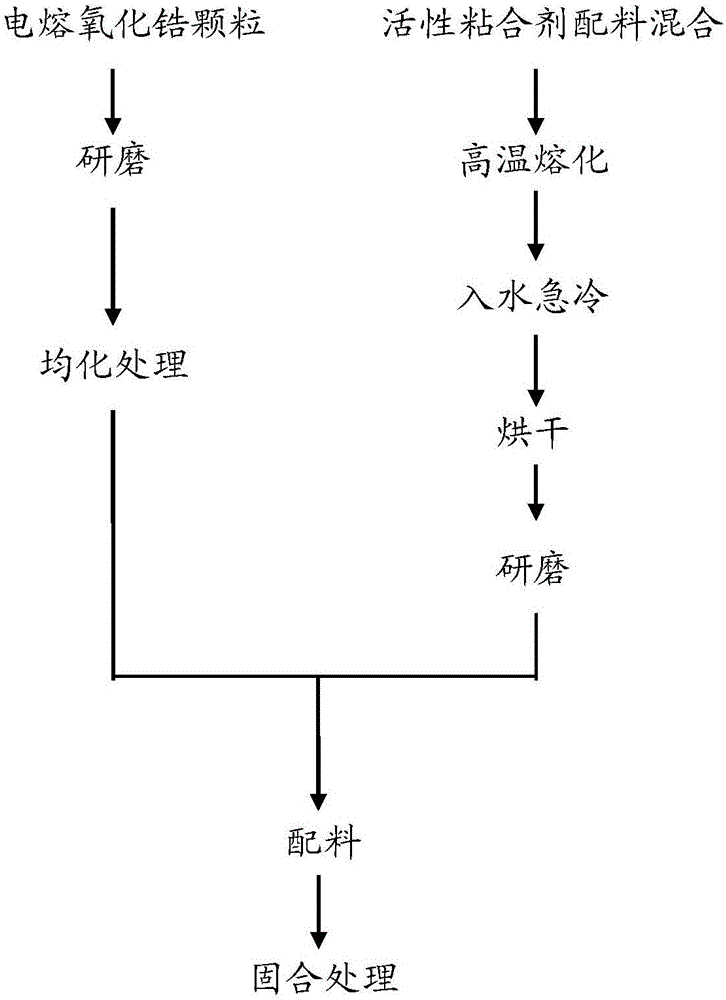

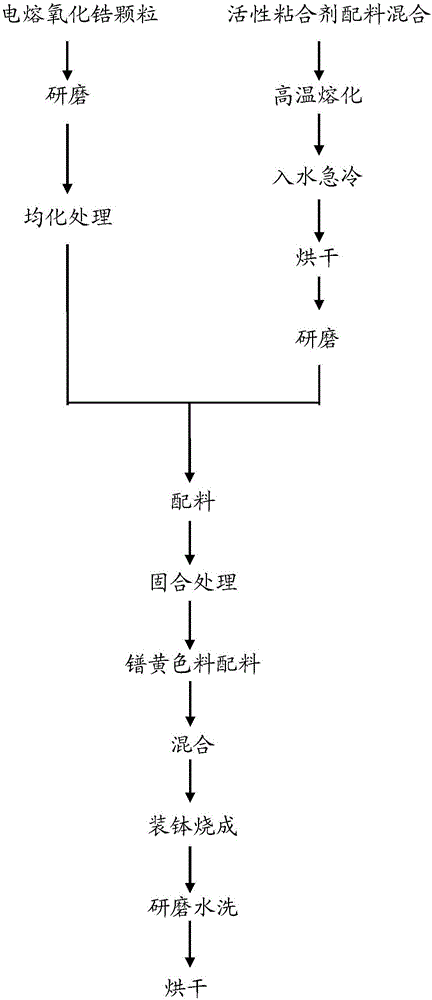

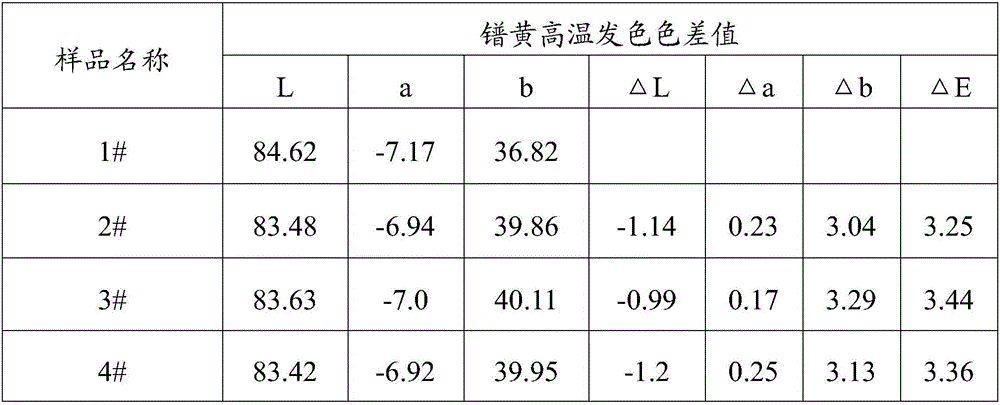

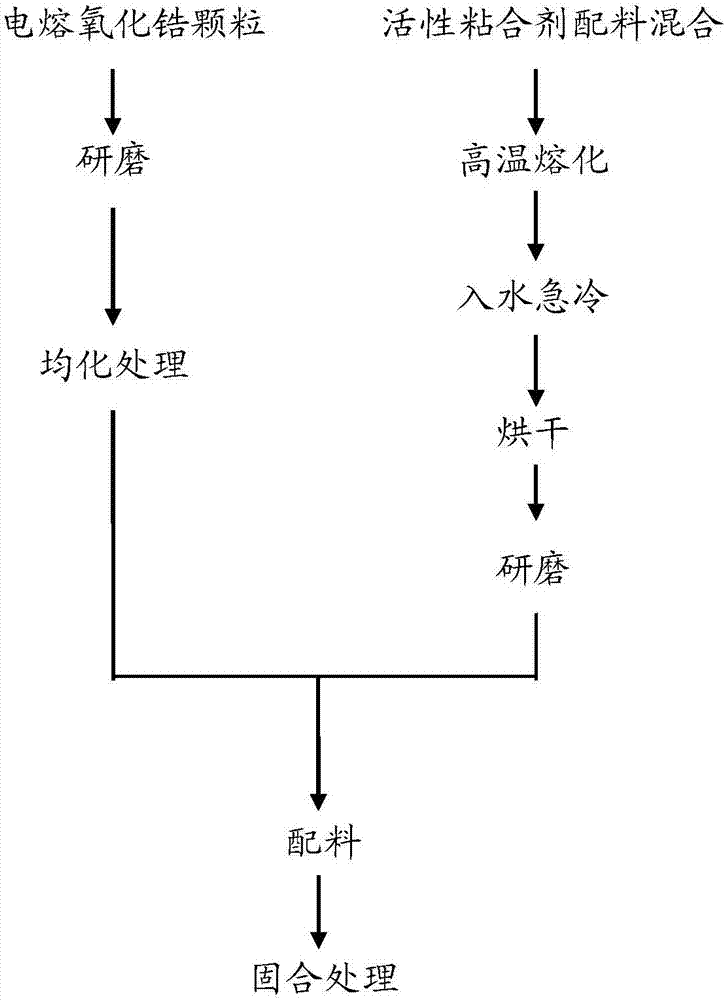

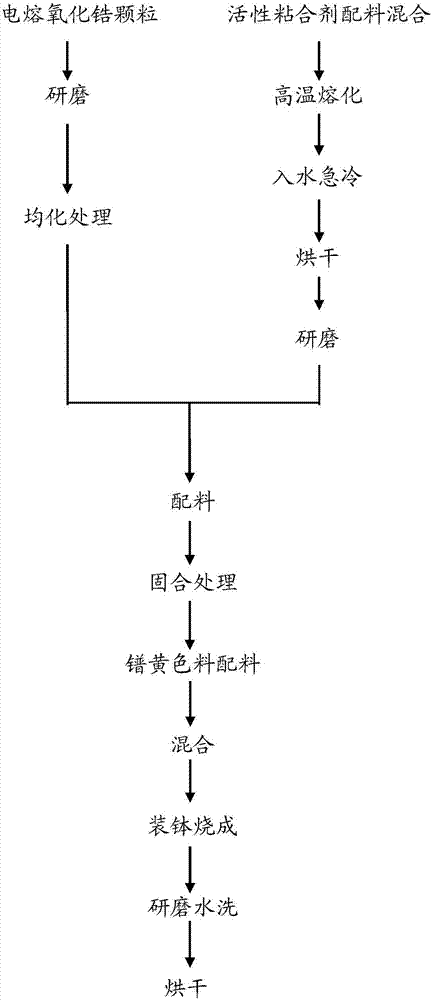

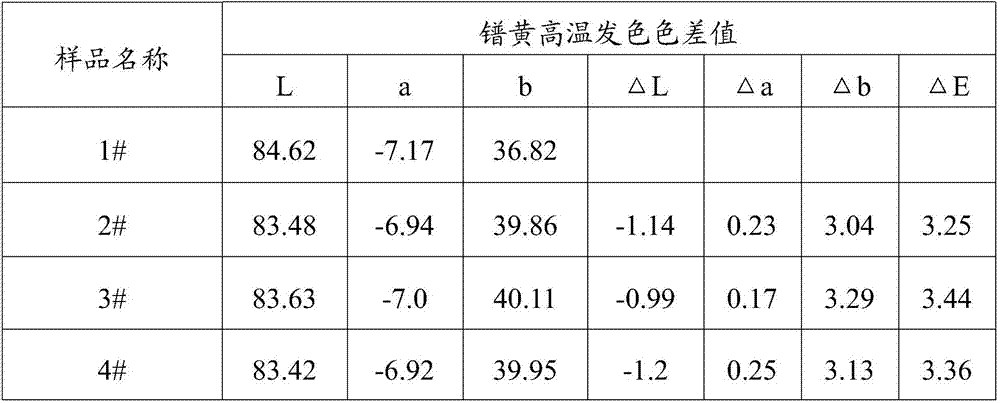

Preparation method for modified fused zirconia and praseodymium yellow pigment

ActiveCN104529541AReduce manufacturing costMeet the use requirementsPigment flushingAdhesiveTemperature resistance

The invention relates to a preparation method for modified fused zirconia and praseodymium yellow pigment. The method includes: firstly conducting grinding and homogenization treatment to control the grain composition of fused zirconia in a reasonable scope, improving the specific surface area of fused zirconia, and then adding an appropriate active adhesive to conduct mixing so as to improve the reaction activity of fused zirconia, thus obtaining modified fused zirconia with specific surface area and reaction activity both close to chemical zirconium. The ceramic pigment produced from the modified fused zirconia has temperature resistance close to that of high temperature resistant ceramic pigment prepared from chemical zirconium. The modified fused zirconia can completely replace chemical zirconium to produce high temperature resistant ceramic pigment, the application bottleneck of fused zirconia in the high-end ceramic pigment field can be overcome, and the production cost of high temperature resistant ceramic pigments is reduced.

Owner:SANXIANG ADVANCED MATERIALS

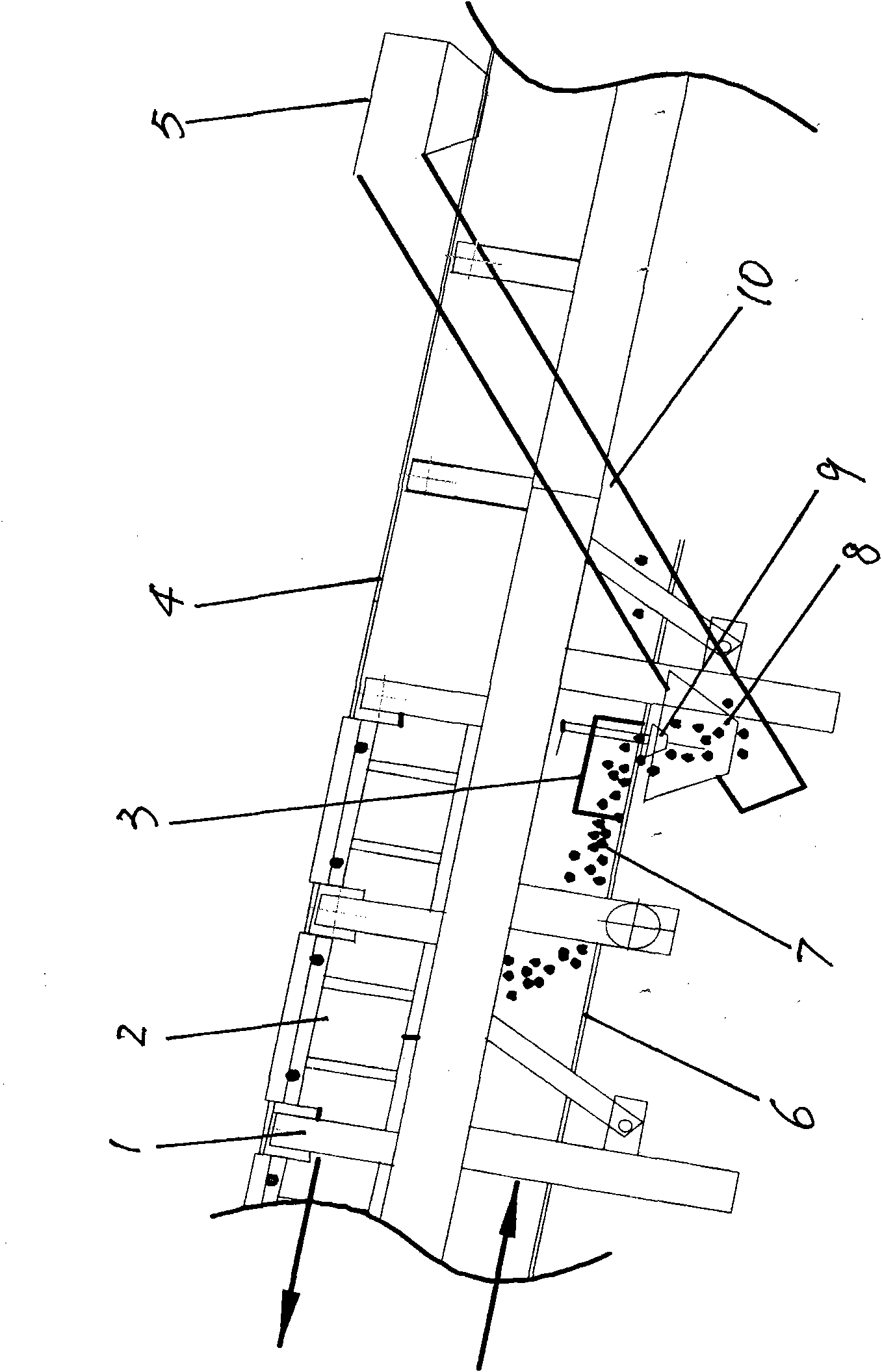

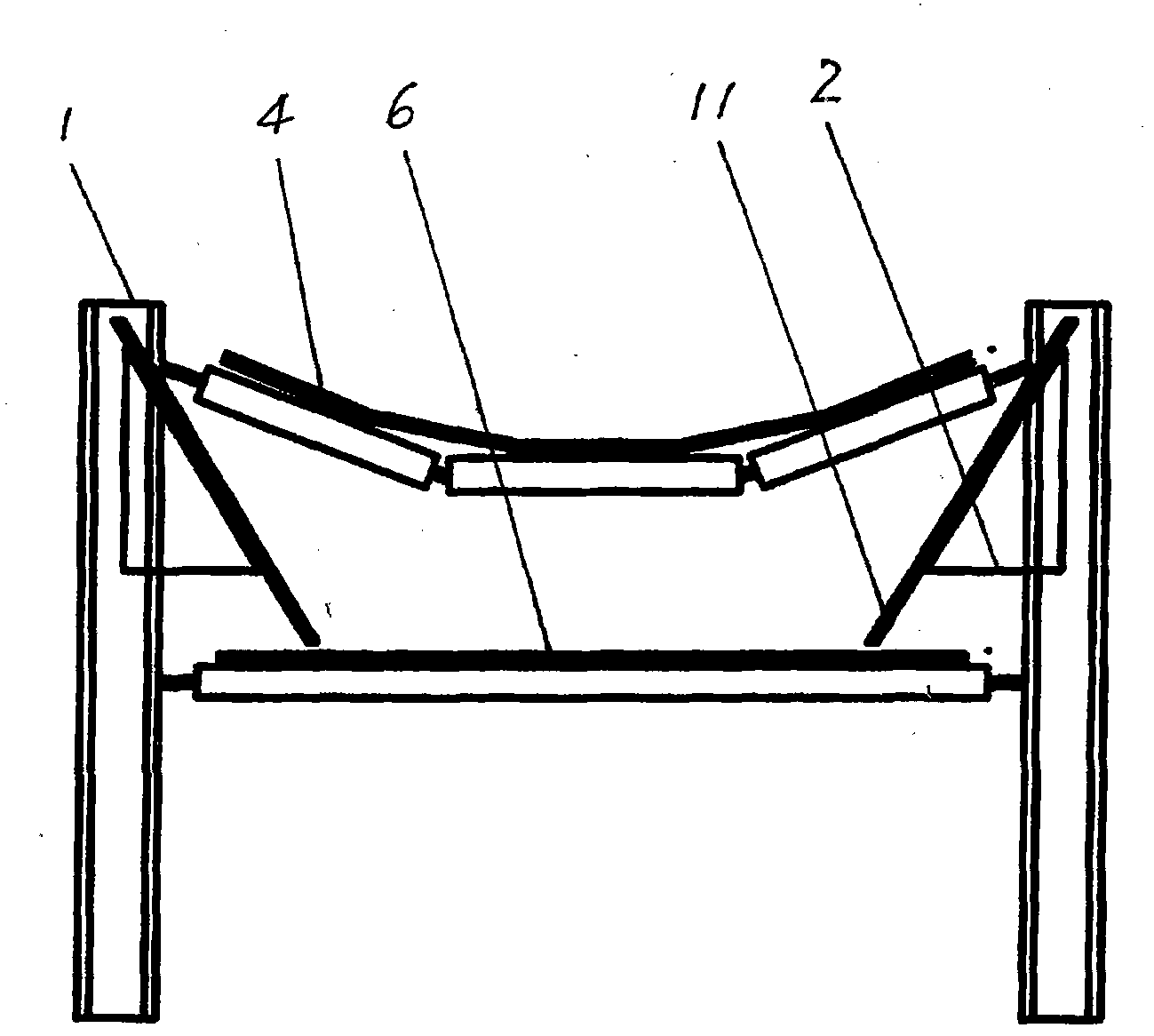

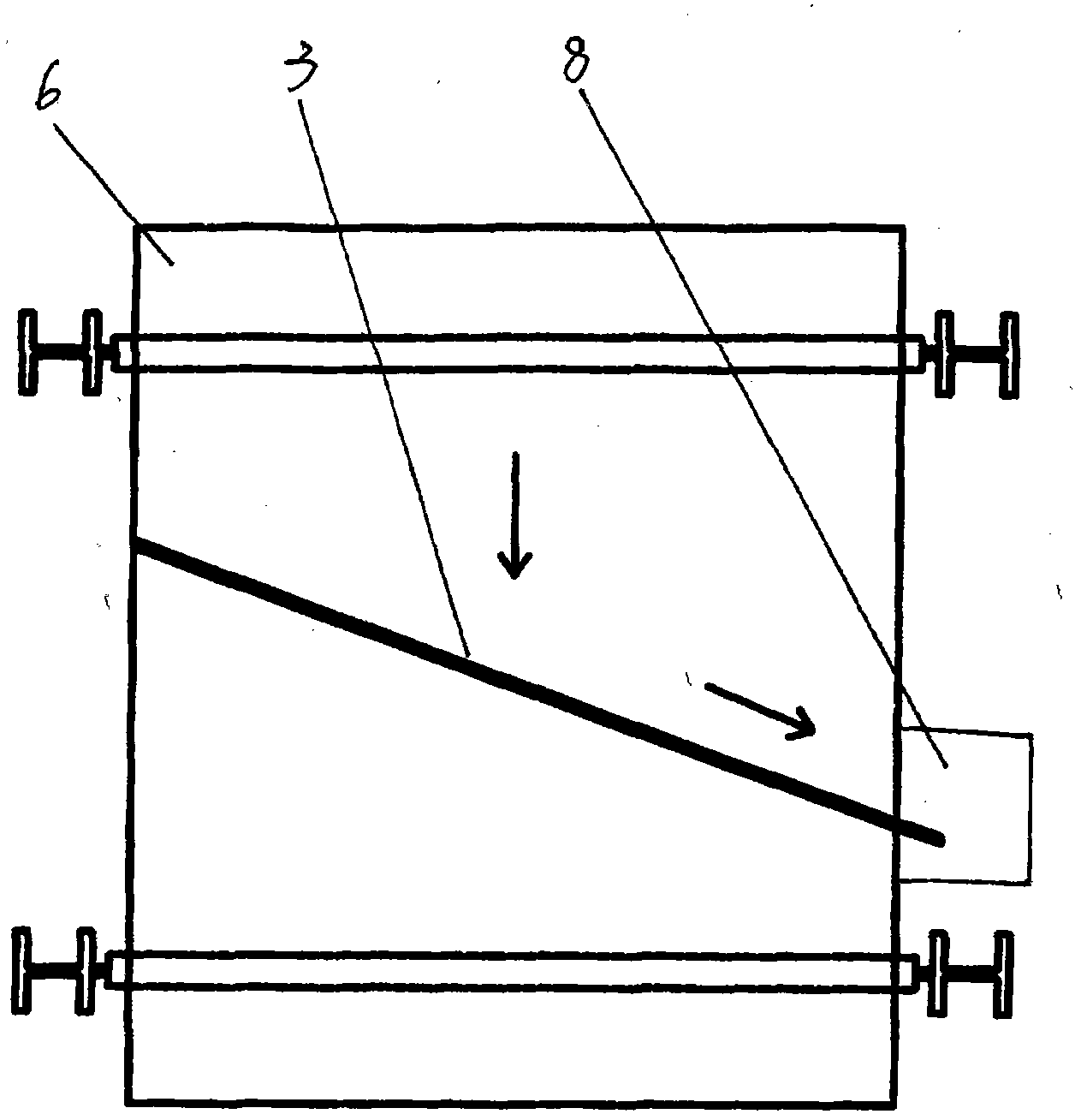

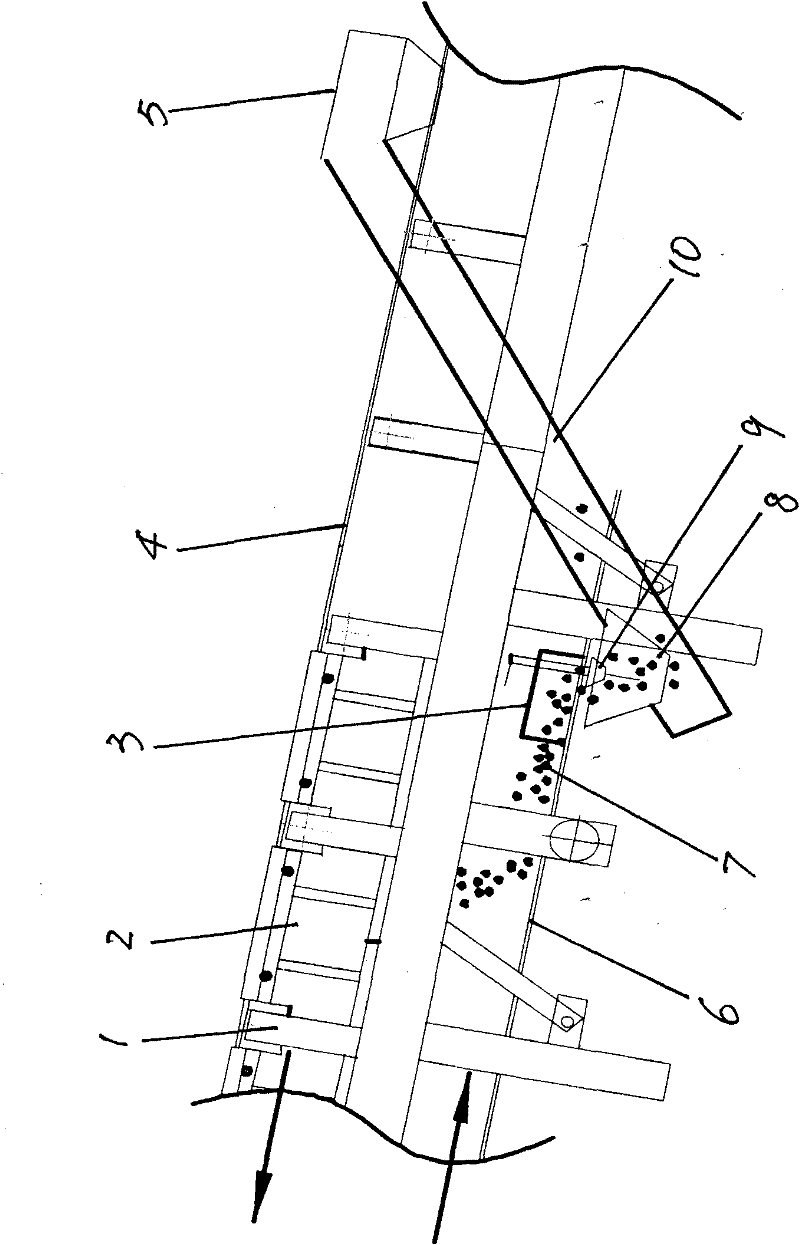

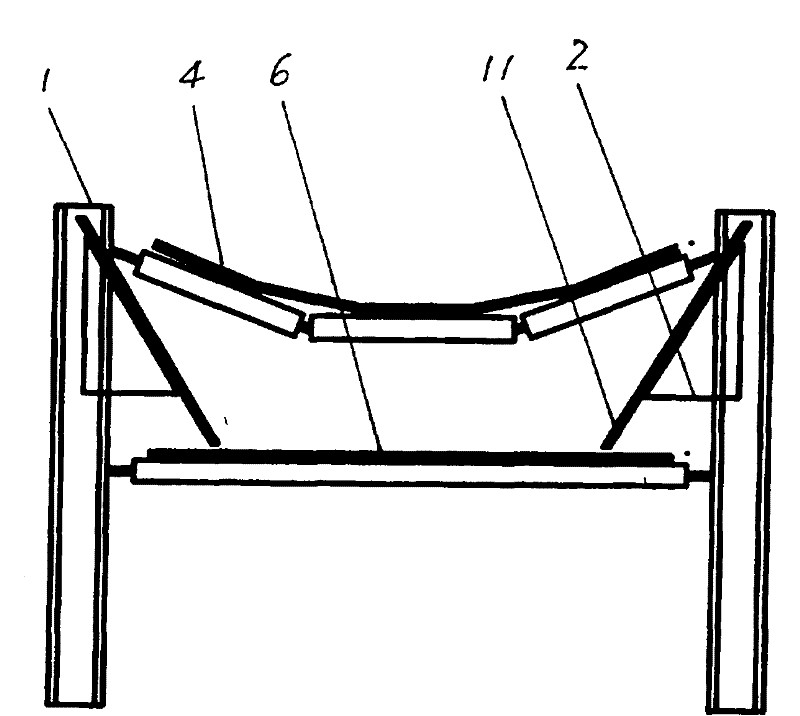

Automatic cleaning method of sprinkled coal in belt conveyance

The invention relates to an automatic cleaning method of sprinkled coal in belt conveyance, which comprises the following steps of: firstly installing a coal blocking plate between an upper belt and a lower belt at both sides of the frame of a belt conveyor, installing a sprinkled coal collecting baffle plate in the vertical direction on the frame in front of the tail of the belt conveyor, building a coal falling bin on the ground below the sprinkled coal collecting baffle plate, installing a coal level sensor inside, and connecting a scraper conveyor between the coal falling bin and a coaling hopper; and when the coal level height reaches a set point, starting the scraper conveyor for conveyance, and when a bin level is low, stopping the scraper conveyor, repeatedly circulating, conveying the slipped coal to the upper belt, and entering a coal flow system to finish the whole cleaning process. The method effectively reduces the belt deviation and the equipment abrasion caused by coal sprinkling, saves the maintenance cost, lightens the labor intensity, improves the equipment conveying capacity, greatly reduces the belt replacing investment and solves the difficult problems that cargos with small adhesive force can not be conveyed by a belt and the coal is sprinkled on the belt.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

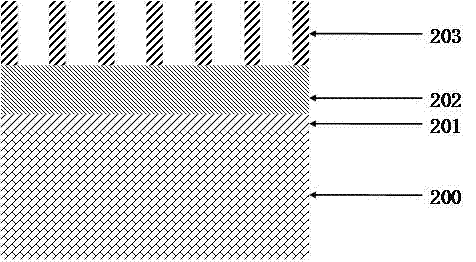

Method for preparing gate stack of metallic nano crystal memory

InactiveCN101908477ASolve Application BottlenecksIncrease costSemiconductor/solid-state device manufacturingSemiconductor devicesGate stackPolyimide membrane

The invention belongs to the technical field of semiconductor memories, and particularly relates to a method for preparing a gate stack of a metallic nano crystal memory. The method comprises the following steps of: depositing a tunneling layer on a single crystal silicon substrate; spinning a layer of polyimide film on the tunneling layer; putting an anodic aluminum oxide template on the polyimide film serving as an etching mask; performing reactive ion etching on the polyimide film to form a polyimide mask; removing the anodic aluminum oxide template; depositing a layer of ultra-thin metal in the polyimide mask; removing the polyimide mask by adopting lift-off technology; depositing a barrier layer; and depositing a gate electrode. Because anodic aluminum oxide is used as a non-photolithographic mask plate, the formed nano crystal array has high density and uniform size distribution.

Owner:FUDAN UNIV

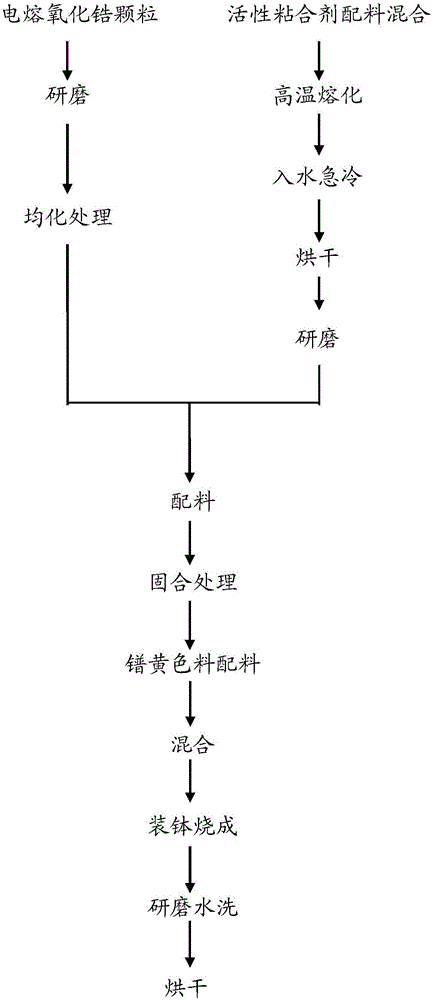

High-temperature-resistant high-colorability praseodymium yellow material preparation method

The invention relates to a high-temperature-resistant high-colorability praseodymium yellow material preparation method. By grinding and homogenizing, grain composition of electrically fused zirconia is controlled in a reasonable range to increase the specific surface area of the electrically fused zirconia; appropriate active adhesives are added and fixed to the electrically fused zirconia to improve reaction activity of the electrically fused zirconia, so that modified electrically fused zirconia approximate to chemical zirconium in specific surface area and reaction activity is obtained. Temperature resistance of ceramic pigments prepared from the high-temperature-resistant modified electrically fused zirconia is approximate to that of high-temperature-resistant ceramic pigments prepared from chemical zirconium, so that the high-temperature-resistant modified electrically fused zirconia can completely substitute for chemical zirconium in production of the high-temperature-resistant ceramic pigments. An application bottleneck of the electrically fused zirconia in the field of high-end ceramic pigments is overcome, and production cost of the high-temperature-resistant ceramic pigments is reduced.

Owner:SANXIANG ADVANCED MATERIALS

Welding material and welding method for fusion welding butt joint transition layer of titanium steel clad plate

ActiveCN107984054BSolve Application BottlenecksHigh strengthArc welding apparatusWelding/cutting media/materialsButt weldingManganese

The invention discloses welding materials for butt welding of transition layers of a titanium clad steel plate and a welding method of the welding materials, and belongs to the technical field of metal material welding. The welding materials comprise a welding material for a surfacing layer and a near-titanium layer, a welding material for a bottoming layer, a welding material for a steel layer and a welding material for a titanium layer, wherein the welding material for the surfacing layer and the near-titanium layer comprises, by weight percentage, less than or equal to 0. 011% of carbon, less than or equal to 0.32% of silicon, 2.0-4.0% of manganese, less than or equal to 0.01% of phosphorus, less than or equal to 0.01% of sulfur, 10-17% of chromium, 2-16% of molybdenum, less than or equal to 2.0% of copper, less than or equal to 5.0% of ferrum and the balance nickel; and the welding material for the bottoming layer comprises more than or equal to 99.9% of nickel. The welding methodcomprises the following step that a groove form of a welding joint is designed to be an X-shaped groove, surfacing is carried out on the groove of the surfacing layer, then the near-titanium layer isfilled and welded with the near-welding material for the near-titanium layer, welding is carried out on the steel layer by using the welding material of ordinary carbon steel, and finally welding is carried out on the titanium layer by using an industrial TA2 welding wire. The welding materials and the welding method have the advantage that the fusion welding butt joint of the titanium clad steelplate has relatively high strength and toughness; and the problem of application bottleneck of welding of the titanium clad steel plate can be solved.

Owner:CENT IRON & STEEL RES INST

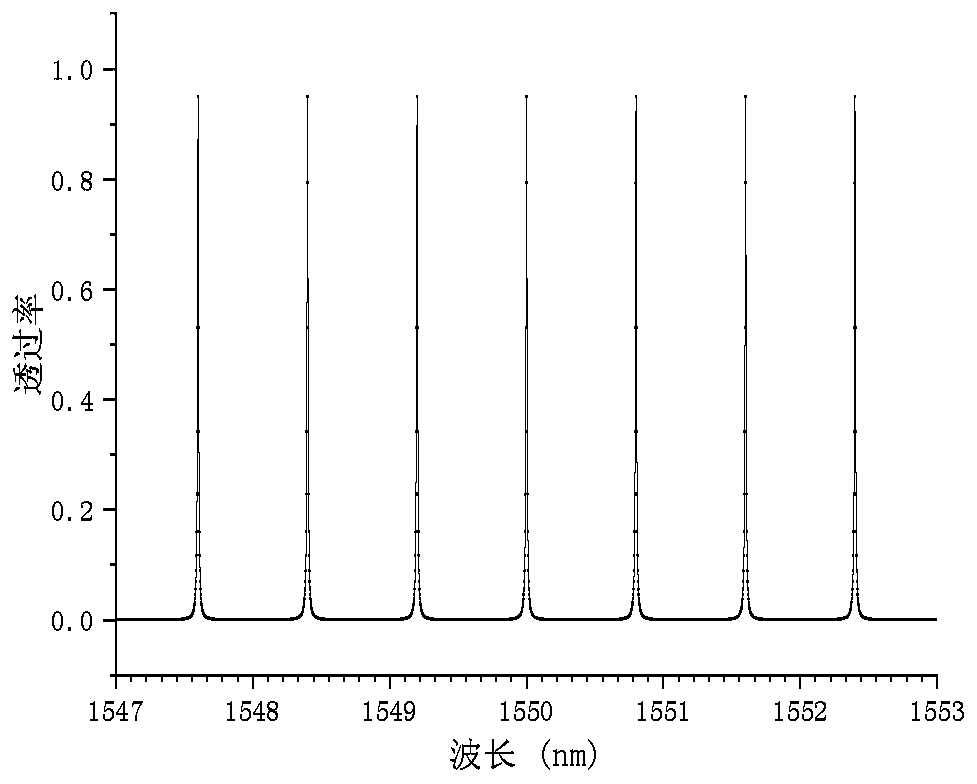

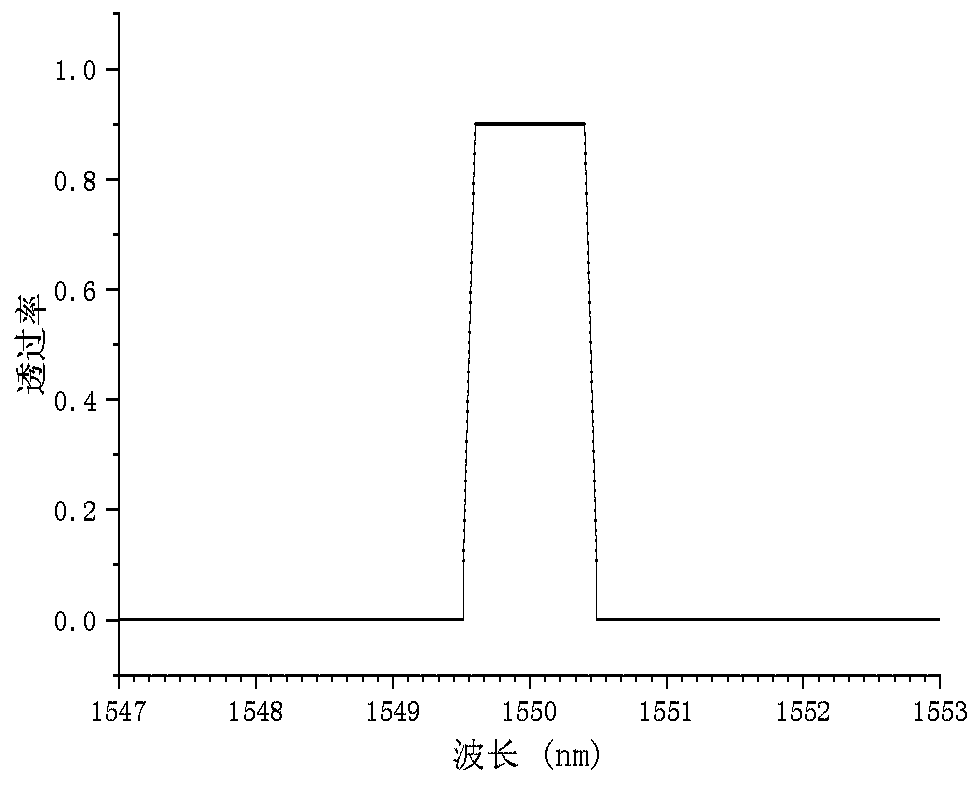

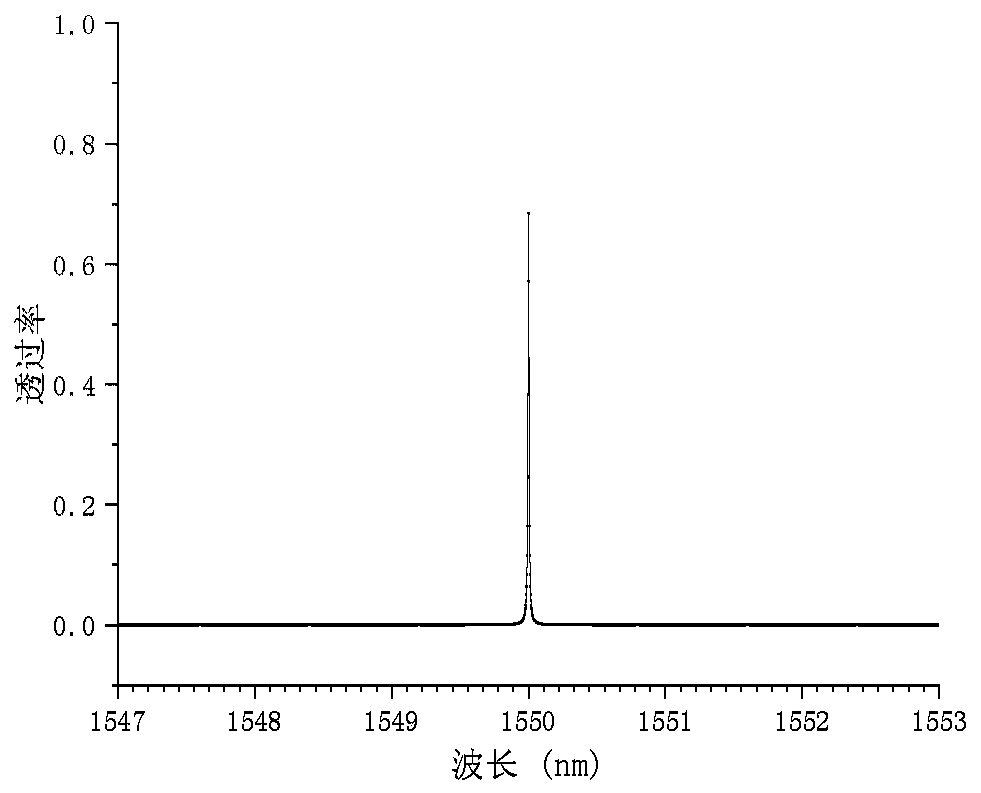

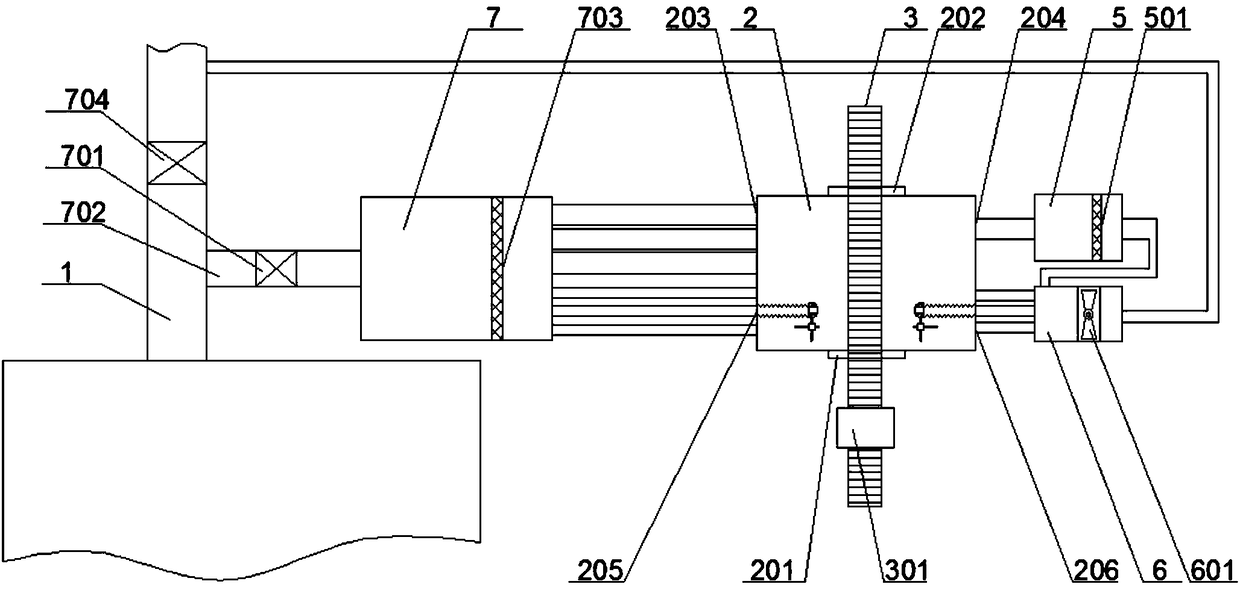

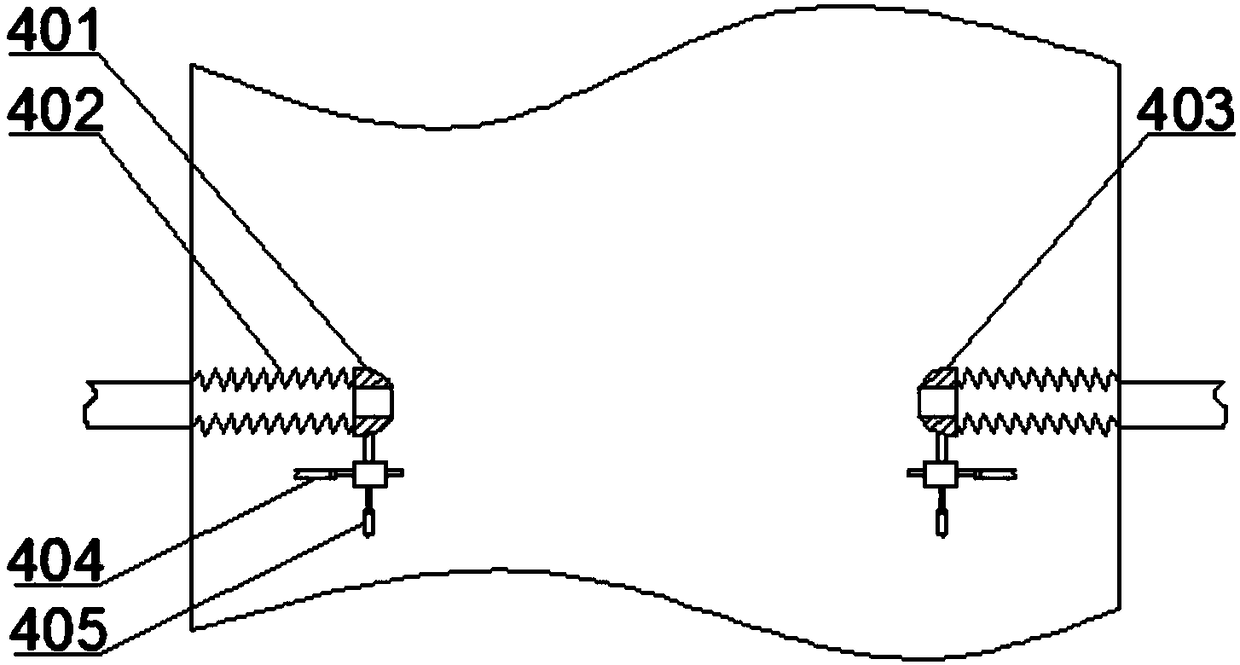

Miniature narrow-band filter for multistage filtering

PendingCN110749959ASolve Application BottlenecksImprove efficiencyOptical light guidesWave shapeEngineering

The invention discloses a miniature narrow-band filter for multistage filtering, comprising an input collimator, a first-stage filter, an FP (Fabry-Perot) cavity and an output collimator, wherein theinput collimator is used for performing beam expansion on an input optical signal and then transmitting the optical signal into the first-stage filter through a free space; the first-stage filter is used for performing first-stage filtering on the optical signal transmitted by the input collimator and then transmitting the optical signal into the FP cavity through the free space; the FP cavity isused for performing narrow-band filtering on the optical signal filtered by the first-stage filter and then transmitting the optical signal to the output collimator through the free space; and the output collimator is used for receiving the optical signal which is transmitted by the FP cavity after being subjected to narrow-band filtering, and performing coupling and output on the optical signal.According to the miniature narrow-band filter of the invention, the first-stage filter is combined with the FP cavity, so that an application bottleneck of evenly spaced comb-shaped waveforms of an FPcavity filter can be solved, and narrow-band filtering in a large spectral range can be achieved; at the same time, control on a working temperature is achieved based on a thermistor and a semiconductor cooler TEC, thereby improving reliability of the filter.

Owner:UNIV OF SCI & TECH OF CHINA

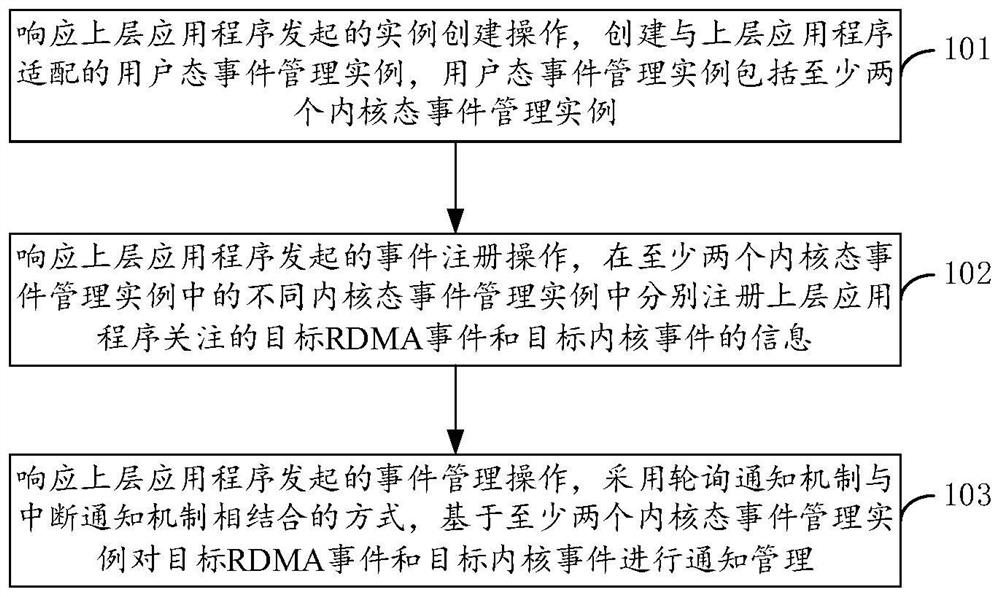

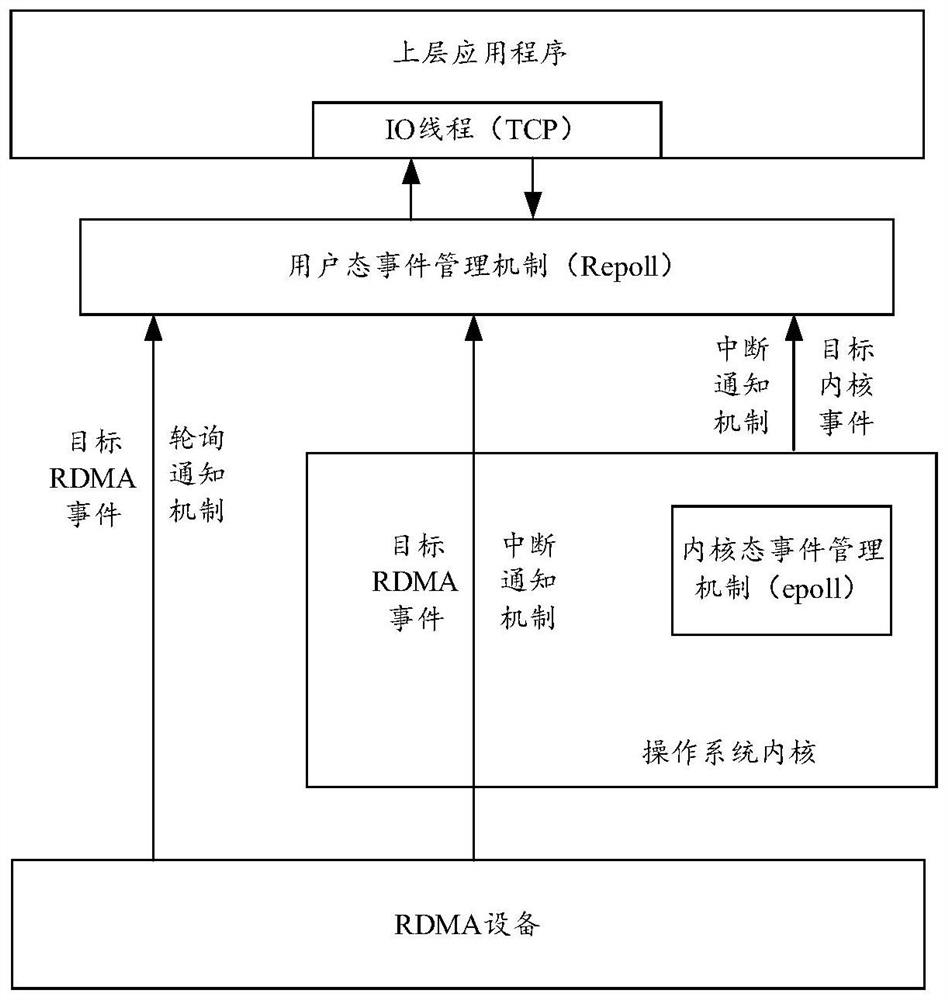

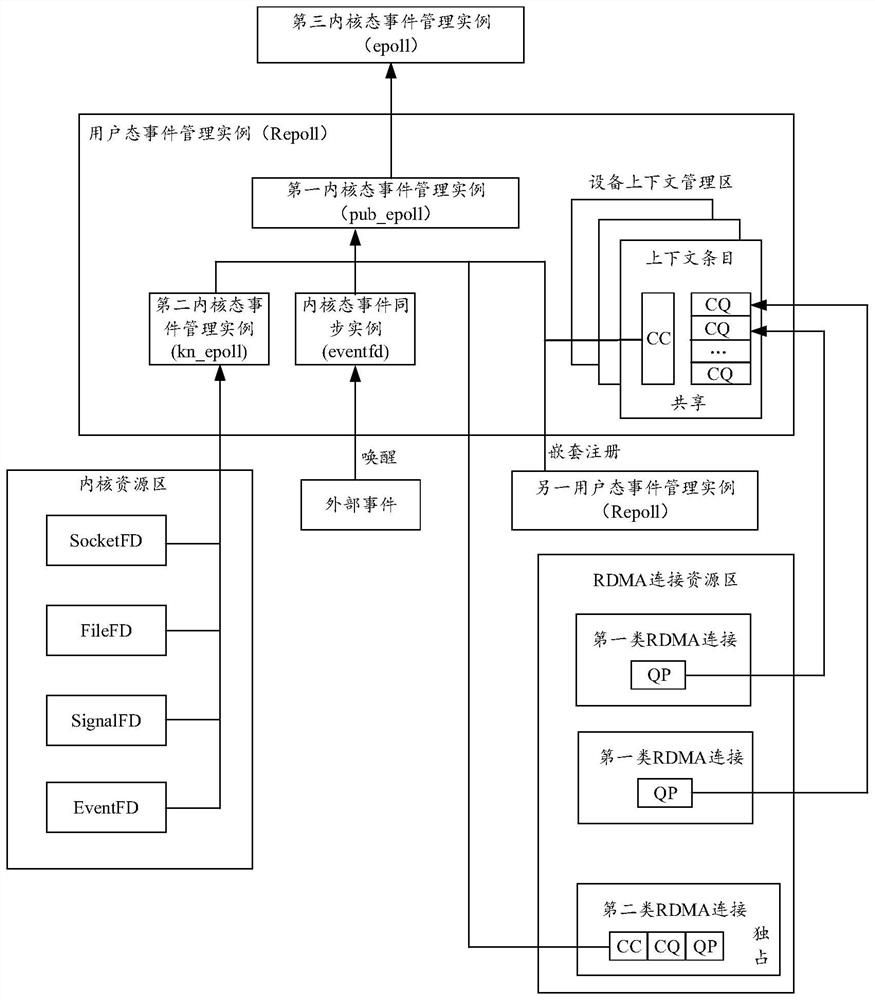

RDMA event management method and device, computer equipment and storage medium

PendingCN114265713ABroaden application scenariosSolve application bottlenecksInterprogram communicationUser stateEvent planning

The embodiment of the invention provides an RDMA event management method and device, computer equipment and a storage medium. In the embodiment of the invention, a new user state event management mechanism is additionally arranged between an upper-layer application program and an operating system kernel, and the user state event management mechanism is used for packaging a plurality of kernel state event management instances to obtain a user state event management instance facing the upper-layer application program; the user state event management instance controls different kernel state event management instances contained in the user state event management instance to at least simultaneously perform notification management on the RDMA event and the kernel event, so that the problem of event notification compatibility in a mixed running scene of two protocols is solved, the application scene of the RDMA technology can be further expanded, and the application bottleneck problem faced by the RDMA technology is solved.

Owner:ALIBABA (CHINA) CO LTD

Preparation method of high-temperature-resistant modified fused zirconia and praseodymium yellow pigment

The invention relates to a preparation method of high-temperature-resistant modified fused zirconia and praseodymium yellow pigment. Grain composition of fused zirconia is controlled within a reasonable range through grinding and homogenizing treatment firstly, the specific surface area of fused zirconia is increased, then a proper reactive adhesive is added to be fixedly combined with fused zirconia, the reaction activity of fused zirconia is increased, so that modified fused zirconia with the specific surface area and the reaction activity close to those of chemical zirconium is obtained, the temperature resistance of ceramic pigment prepared from high-temperature-resistant modified fused zirconia is close to that of high-temperature-resistant ceramic pigment prepared from the chemical zirconium, the ceramic pigment can completely replace the high-temperature-resistant ceramic pigment prepared from the chemical zirconium, the application bottleneck of fused zirconia in the field of high-end ceramic pigment is broken through, and the production cost of the high-temperature-resistant ceramic pigment is reduced.

Owner:SANXIANG ADVANCED MATERIALS

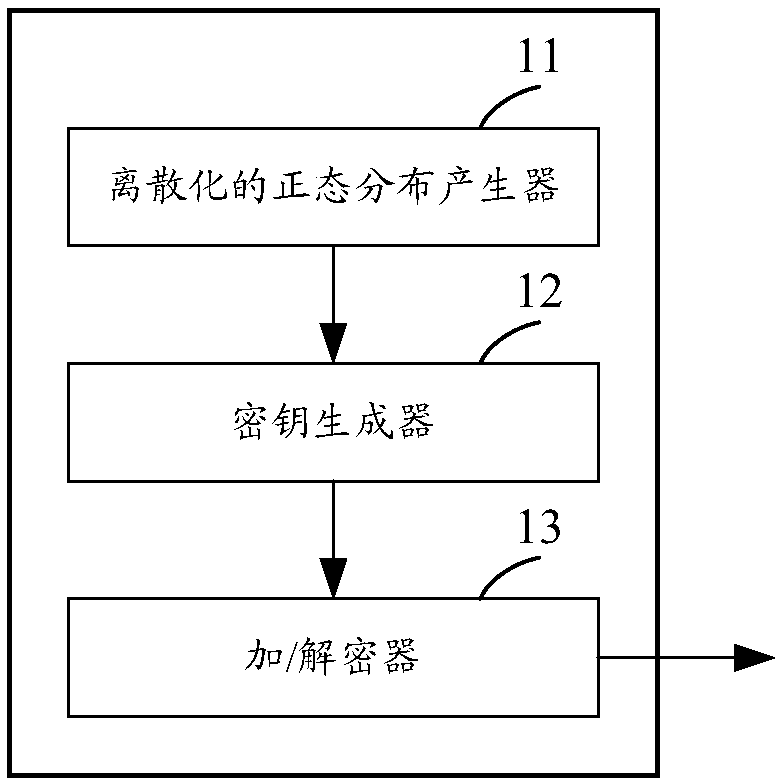

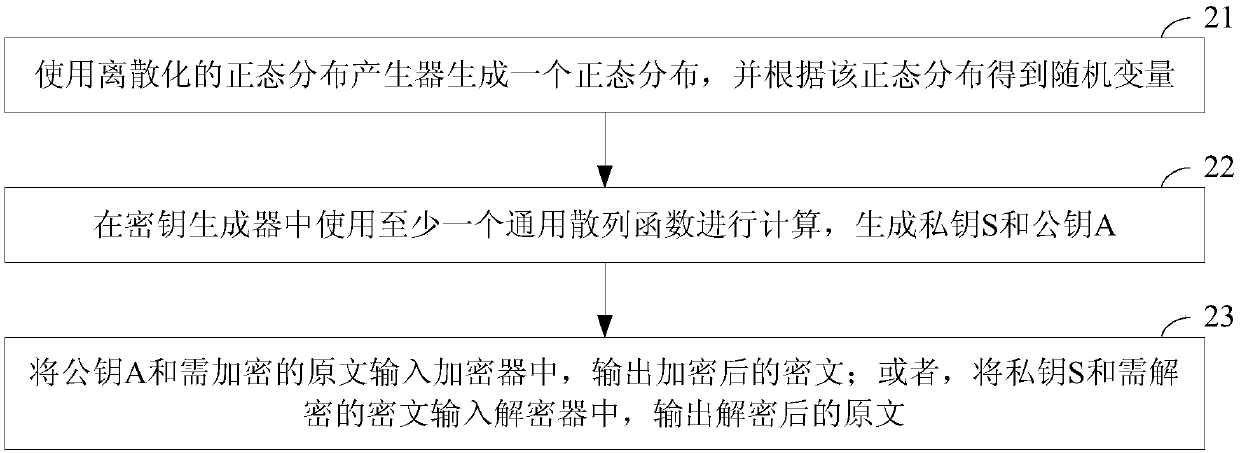

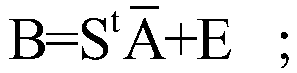

Encryption and decryption device and encryption and decryption method based on universal hash functions

ActiveCN108777614AReduce storageSolve Application BottlenecksKey distribution for secure communicationEncryption apparatus with shift registers/memoriesComputer hardwareComputation complexity

The invention provides an encryption and decryption device and an encryption and decryption method based on universal hash functions. The encryption and decryption device comprises a discretized normal distribution generator, a key generator and an encryption / decryption device body, wherein the discretized normal distribution generator is used for generating a normal distribution and obtaining a random variable according to the normal distribution, the key generator is used for generating a private key S and a public key A by using at least one universal hash function, and the encryption / decryption device body is used for outputting encrypted ciphertext according to the public key A and the original text required to be encrypted or is used for outputting the decrypted original text according to the private key S and the ciphertext required to be decrypted. According to the encryption and decryption device and the encryption and decryption method, the storage and calculation complexitycan be greatly lowered.

Owner:TSINGHUA UNIV

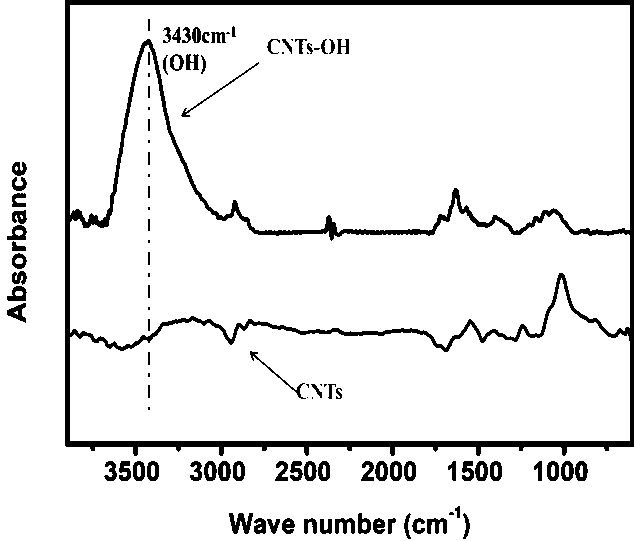

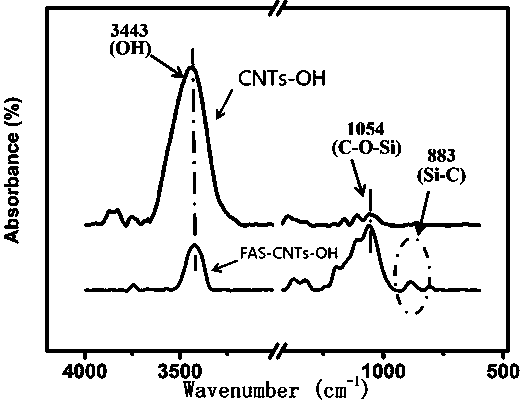

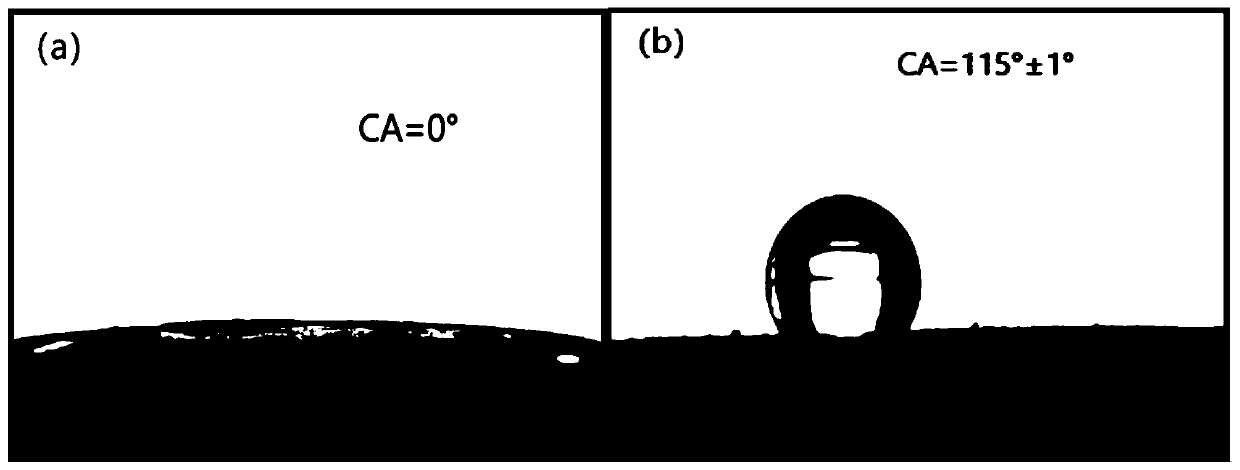

Method for functional modification of carbon nanotubes (CNTs) applicable to composite rubber system

InactiveCN111187449AEasy to operateNo reduction in lengthPigment treatment with organosilicon compoundsRubber materialPolymer science

The invention provides a method for functional modification of CNTs applicable to a composite rubber system. The method comprises the following steps: treating CNTs by using a covalent bond modification method, i.e., a hydrogen peroxide (H2O2) oxidation method so as to form hydroxyl functional groups on the surfaces of CNTs through oxidation; and then subjecting a silane coupling agent, i.e., (heptadecafluoro-1,1,2,2-tetradecyl)trimethoxysilane (CF3(CF2)7CH2CH2Si(OC2H5)3) (AC-FAS) and the hydroxyl groups on the surface of the CNTs to a dehydration condensation reaction so as to successfully introduce the silane coupling agent to the surfaces of the CNTs. A contact angle test result shows that the surfaces of the CNTs functionalized by the method are changed from hydrophilicity to hydrophobicity, so the compatibility of the CNTs with a rubber matrix is effectively improved. A carbon black / carbon nanotube composite rubber material prepared from 5 phr of the functionalized carbon nanotubes has excellent mechanical properties, and the heat-conducting property of the carbon black / carbon nanotube composite rubber material can be improved by 11.9%. The dispersibility of the CNTs and the compatibility between the CNTs and the matrix are well improved; the dispersion of the CNTs effectively promotes the dispersion of the carbon black; and the two fillers, namely the CNTs and the carbonblack, construct a good filler network in the rubber matrix. The functional modification method provided by the invention effectively solves problems in application of the carbon nanotubes to rubber.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method for praseodymium yellow pigment

ActiveCN105859325ANot easy to fadeHigh tinting strengthPigment flushingPigment physical treatmentPigmentPraseodymium

The invention relates to a preparation method for praseodymium yellow pigment. The preparation method comprises the following steps: controlling the grain composition of fused zirconia in a reasonable range through grinding and homogenizing so as to improve the specific surface area of the fused zirconia; and then adding an appropriate active binder and allowing the binder and the fused zirconia to be fixedly bonded so as to improve reaction activity of the fused zirconia. Thus, modified fused zirconia with a specific surface area and reaction activity close to those of chemical zirconium is obtained. Ceramic pigment produced from the high-temperature-resistant modified fused zirconia has temperature tolerance close to that of high-temperature-resistant ceramic pigment prepared from chemical zirconium. The modified fused zirconia can totally replace chemical zirconium for production of high-temperature-resistant ceramic pigment; so bottlenecks in bottleneck of the fused zirconia in the fields of high-class ceramic pigment are overcome, and production cost for the high-temperature-resistant ceramic pigment is reduced.

Owner:SANXIANG ADVANCED MATERIALS

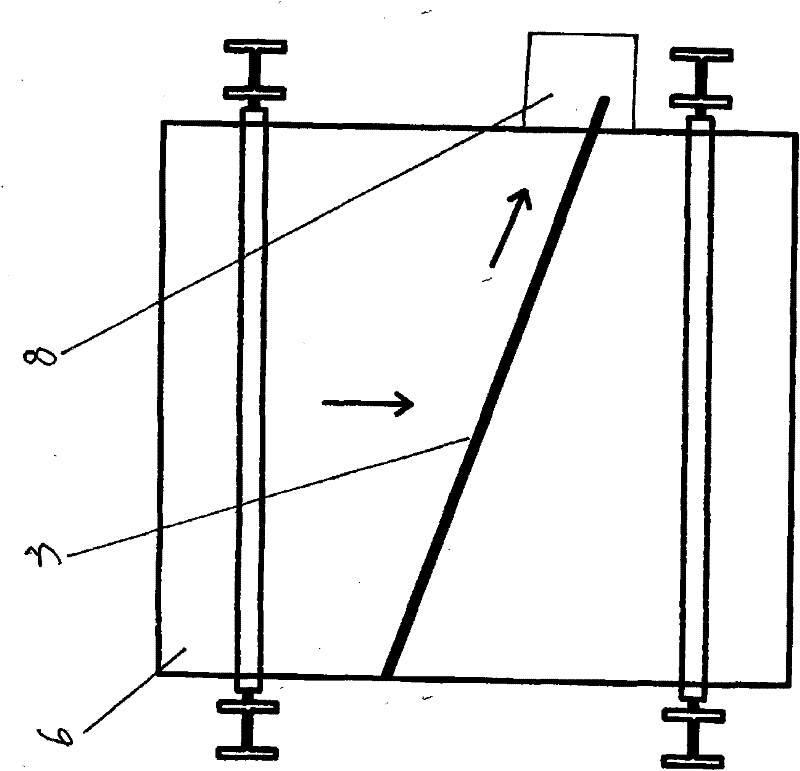

A system for coupling and drying slurry thermal insulation materials by using waste heat of flue gas

ActiveCN106091661BSolve Application BottlenecksQuickly drive application implementationIncreasing energy efficiencyDrying solid materialsFlue gasSlurry

The invention relates to a system for utilizing flue gas residual heat for carrying out coupled drying on a slurry heat preservation material, and belongs to the technical field of energy utilization. The drying system comprises a drying unit connected to the rear end of a flue gas conveying mechanism, a dust removal unit and an air returning unit; the drying unit utilizes flue gas heat for drying the slurry heat preservation material on thermal equipment, a pipeline interior through-flow heating system is further arranged in the drying unit and is used for introducing high-temperature flue gas into the thermal equipment or a pipeline, and therefore drying of the slurry heat preservation material is strengthened; and the drying system can recycle heat of flue gas of a thermal power plant, waste of heat is avoided, the aim that the flue gas heat is used for drying the slurry heat preservation material of the thermal equipment and the pipeline of the equipment can be achieved, the bottleneck problem in the application and popularization process of the slurry heat preservation material is solved, the improvement of the heat preservation effect of the thermal equipment is promoted, and the emissions of heat of the thermal equipment and heat in the conveying pipeline of the equipment are greatly reduced.

Owner:山东大千热力工程有限责任公司

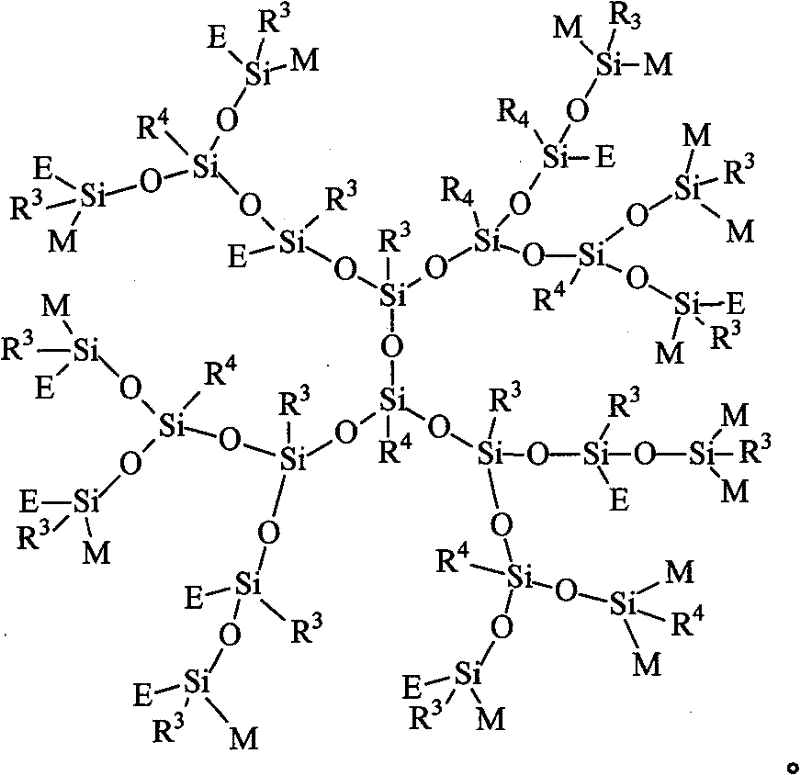

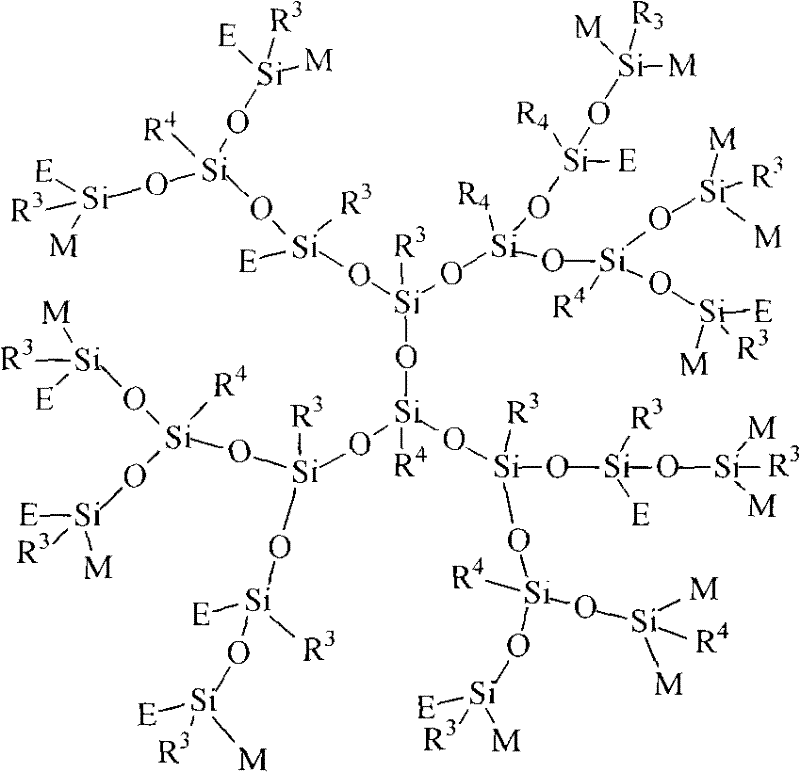

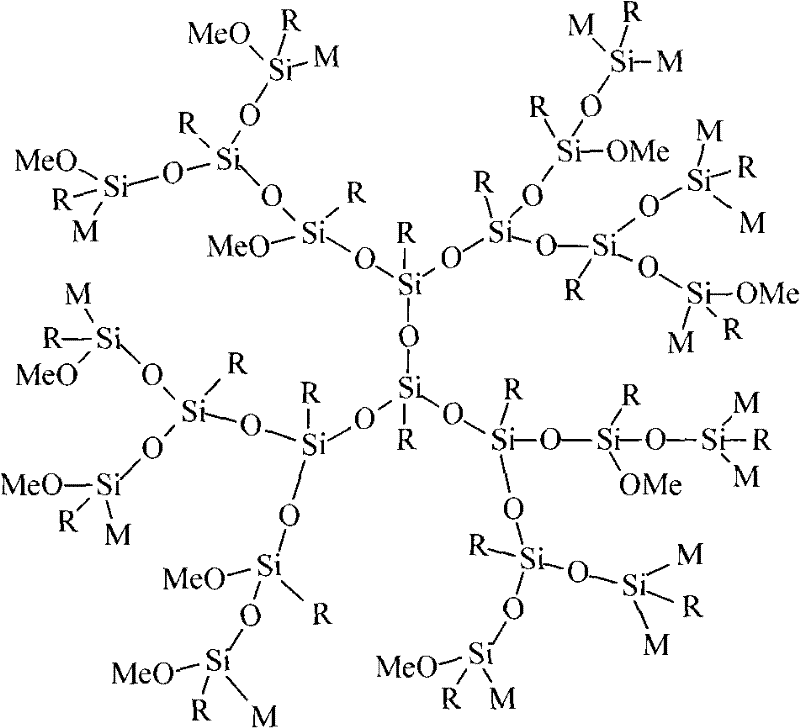

Organosilicon resin composition

Owner:SUZHOU UNIV

Automatic cleaning method of sprinkled coal in belt conveyance

The invention relates to an automatic cleaning method of sprinkled coal in belt conveyance, which comprises the following steps of: firstly installing a coal blocking plate between an upper belt and a lower belt at both sides of the frame of a belt conveyor, installing a sprinkled coal collecting baffle plate in the vertical direction on the frame in front of the tail of the belt conveyor, building a coal falling bin on the ground below the sprinkled coal collecting baffle plate, installing a coal level sensor inside, and connecting a scraper conveyor between the coal falling bin and a coaling hopper; and when the coal level height reaches a set point, starting the scraper conveyor for conveyance, and when a bin level is low, stopping the scraper conveyor, repeatedly circulating, conveying the slipped coal to the upper belt, and entering a coal flow system to finish the whole cleaning process. The method effectively reduces the belt deviation and the equipment abrasion caused by coal sprinkling, saves the maintenance cost, lightens the labor intensity, improves the equipment conveying capacity, greatly reduces the belt replacing investment and solves the difficult problems that cargos with small adhesive force can not be conveyed by a belt and the coal is sprinkled on the belt.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

A kind of nanocomposite fiber material and preparation method thereof

InactiveCN106592005BPayloadAvoid low loadWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsFiberOrganic solvent

The invention provides a method for preparing nanocomposite fiber materials, which includes the following steps: (1) dispersing a plurality of functional nanoparticles in an organic solvent to form a functional nanoparticle suspension; (2) providing a molten state an organic polymer carrier material; (3) spraying the functional nanoparticle suspension onto the molten organic polymer carrier material, so that the plurality of functional nanoparticles are attached to the molten organic polymer The surface of the carrier material; and (4) solidifying the molten organic polymer carrier material obtained in step (3) to obtain the nanocomposite fiber material. The invention also provides a nanocomposite fiber material prepared by the above method. The nanocomposite fiber material realizes effective loading of functional nanoparticles through organic polymer carrier materials, can achieve high loading of functional nanoparticles, and can be used in environmental protection fields such as sewage purification, air purification, antibacterial and anti-virus.

Owner:嘉兴迈之新材料科技有限公司

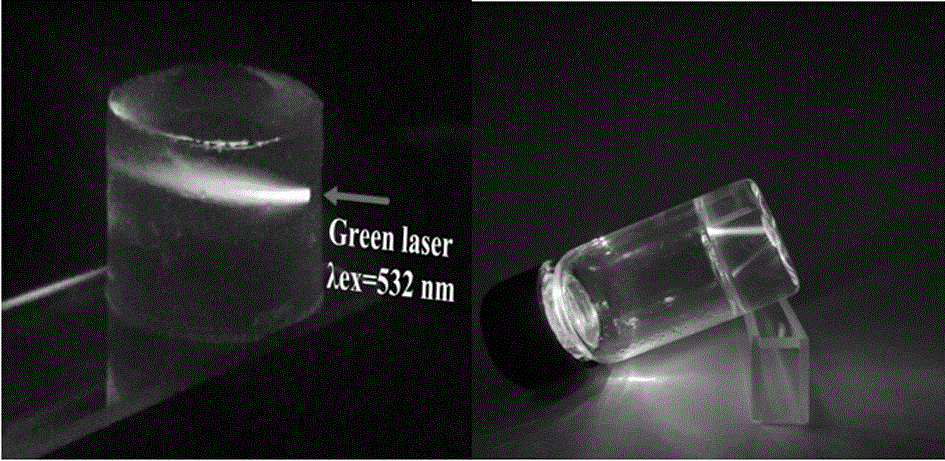

Preparation method of up-conversion resin by taking polydimethylsiloxane as matrix

ActiveCN109880612AImprove conversion efficiencyUp-conversion efficiency reachesElectrolysis componentsOrganic chemistryCross-linkSolution state

The invention discloses a preparation method of up-conversion resin by taking polydimethylsiloxane as a matrix. The preparation method comprises the following steps: in a nitrogen atmosphere, mixing asilane cross-linking agent and a dimethyl siloxane monomer according to a mass ratio of 1:(10-30); performing vacuum treatment, and performing heat preservation at 100 DEG C for 2 hours; and then conducting natural cooling to form polysiloxane; and then, in a nitrogen atmosphere, putting the polysiloxane into an organic solvent containing a photosensitizer and a luminous agent, conducting soakingfor 18-30 hours, and conducting fetching and drying to obtain a polysiloxane-based solid upconversion two-component system. The invention discloses the preparation method of the solid upconversion resin by taking PDMS as the matrix for the first time and green-to-blue light generated by using the solid upconversion resin, a solution-state upconversion system is converted into a solid material, and the solid upconversion resin has high upconversion efficiency and has potential application value in the aspects of hydrogen production by photolysis of water and photosynthesis.

Owner:SUZHOU UNIV OF SCI & TECH

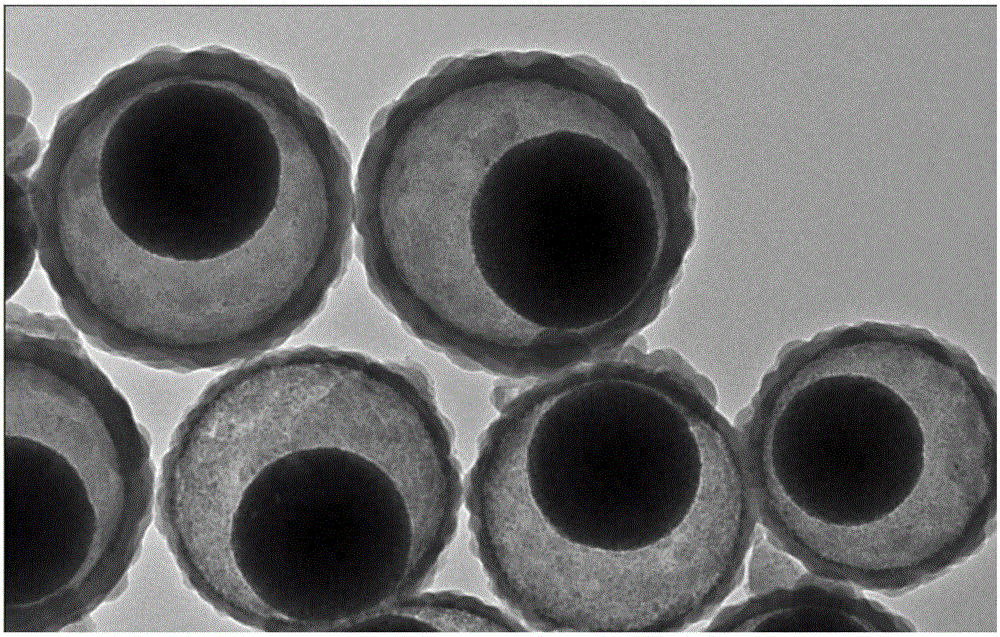

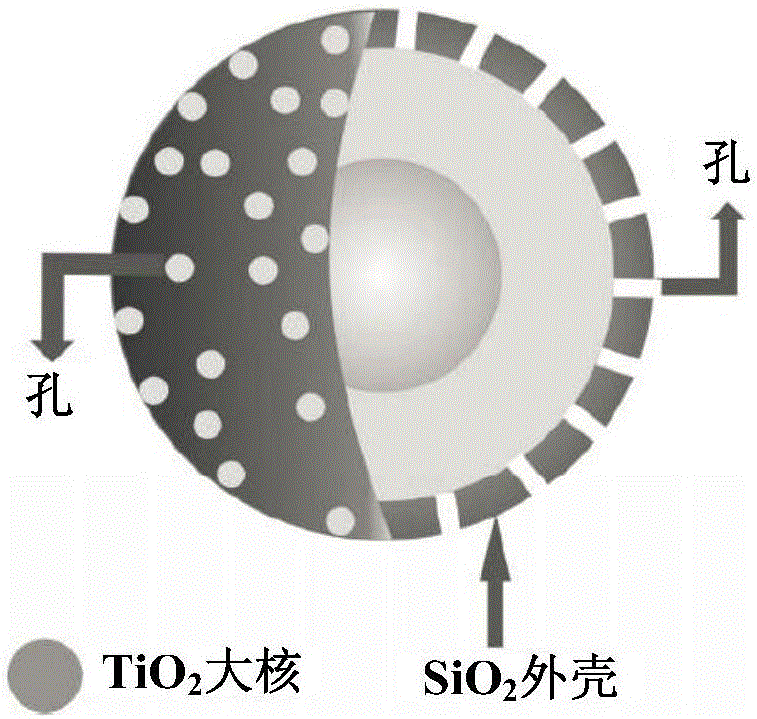

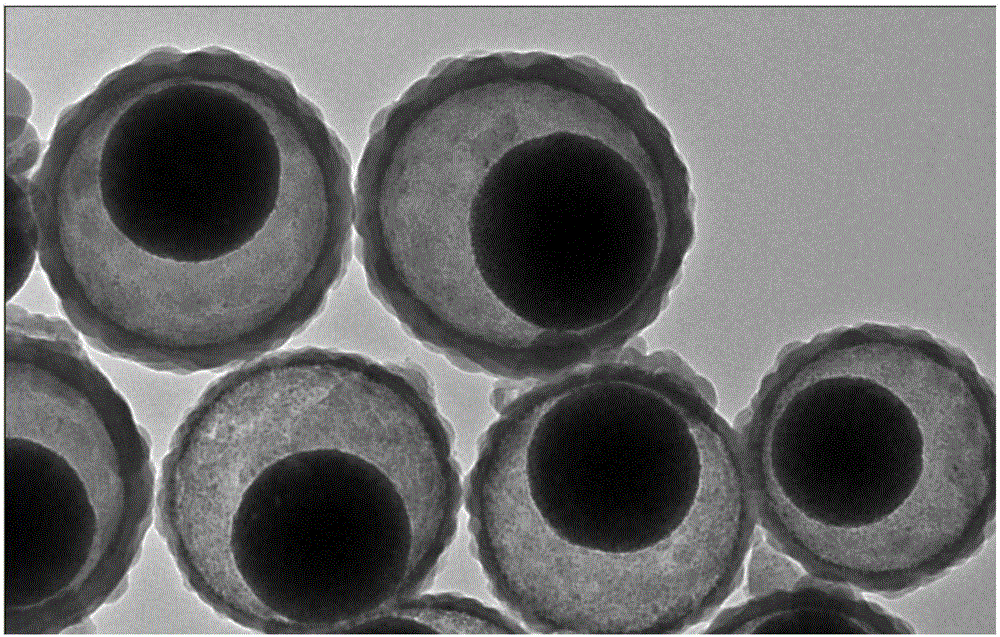

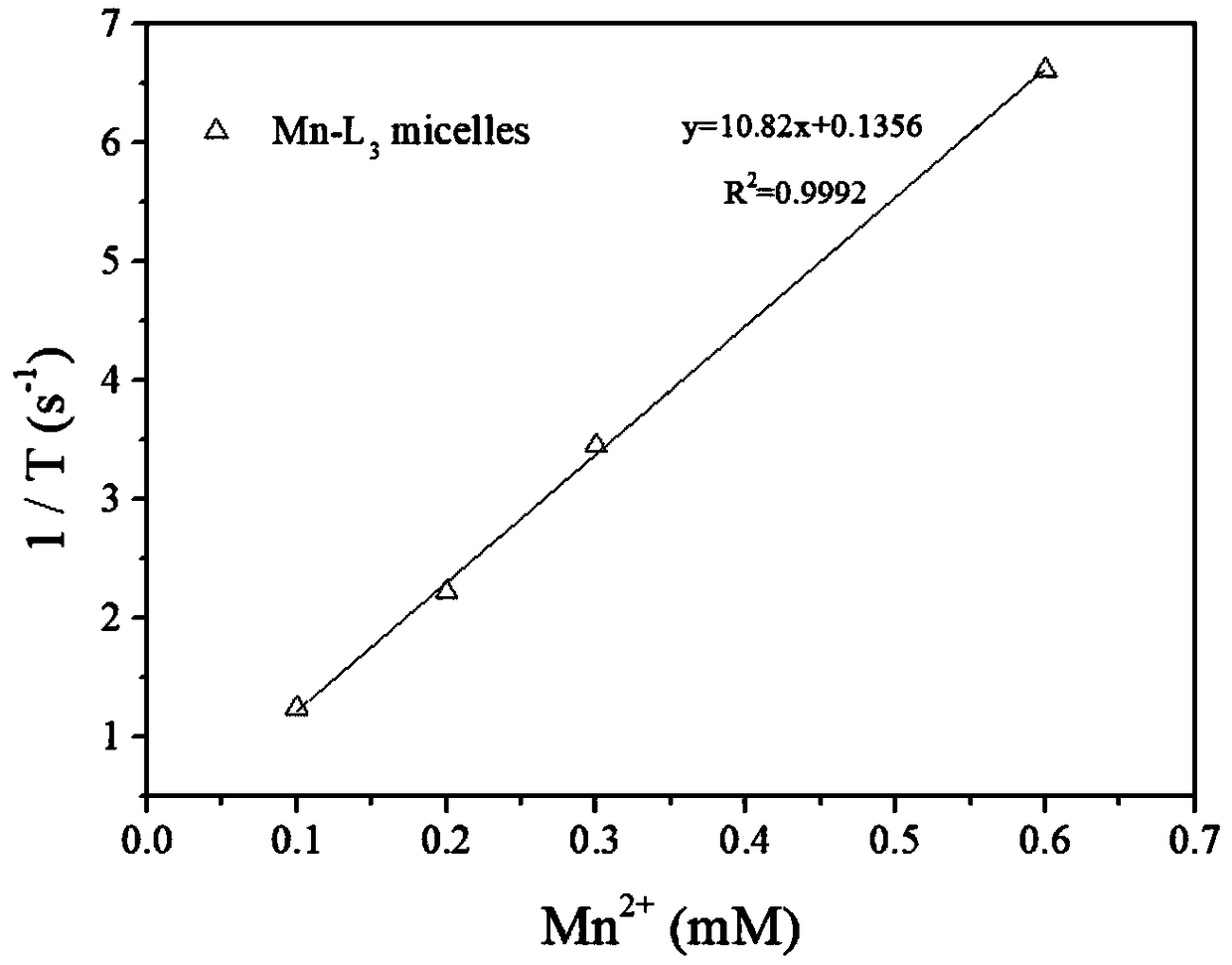

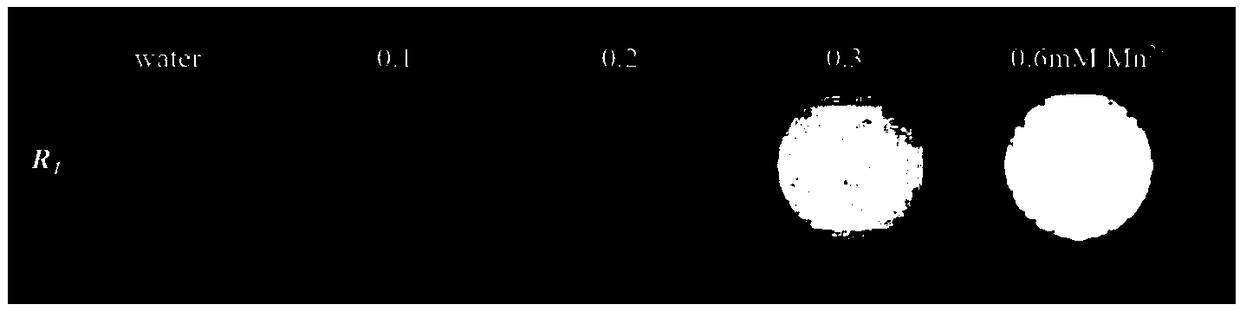

Preparation method of supermolecule polyelectrolyte micelle magnetic resonance imaging contrast agent

ActiveCN108888781ASalt stableSolve Application BottlenecksDispersion deliveryEmulsion deliverySupermoleculeMicelle

The invention relates to a preparation method of a supermolecule polyelectrolyte micelle magnetic resonance imaging contrast agent. A supermolecule with negative electricity is formed by coordinationand self-assembling of a water-soluble tridentate ligand and a paramagnetic transition metal element; and metal type core-shell structure micelle is prepared through electrostatic interaction with a block polymer P2MVP41-b-PEO205 with a positive electricity segment. The tridentate ligand is introduced and the hydrophobicity and the branching degree of a polyelectrolyte micelle core layer are improved, so that the prepared micelle has salt stability, an application bottleneck of traditional polyelectrolyte micelle in the field of biology is overcome and the micelle has an excellent relaxation property. The preparation method is convenient and rapid and easy to control, and has a wide application prospect in the fields of biomedicines and magnetic resonance imaging.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing gate stack of metallic nano crystal memory

InactiveCN101908477BSolve Application BottlenecksGood removal effectSemiconductor/solid-state device manufacturingSemiconductor devicesGate stackPolyimide membrane

The invention belongs to the technical field of semiconductor memories, and particularly relates to a method for preparing a gate stack of a metallic nano crystal memory. The method comprises the following steps of: depositing a tunneling layer on a single crystal silicon substrate; spinning a layer of polyimide film on the tunneling layer; putting an anodic aluminum oxide template on the polyimide film serving as an etching mask; performing reactive ion etching on the polyimide film to form a polyimide mask; removing the anodic aluminum oxide template; depositing a layer of ultra-thin metal in the polyimide mask; removing the polyimide mask by adopting lift-off technology; depositing a barrier layer; and depositing a gate electrode. Because anodic aluminum oxide is used as a non-photolithographic mask plate, the formed nano crystal array has high density and uniform size distribution.

Owner:FUDAN UNIV

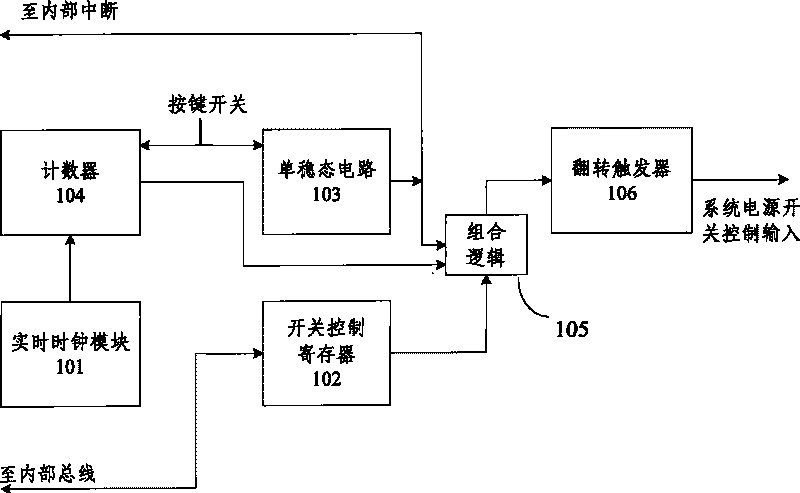

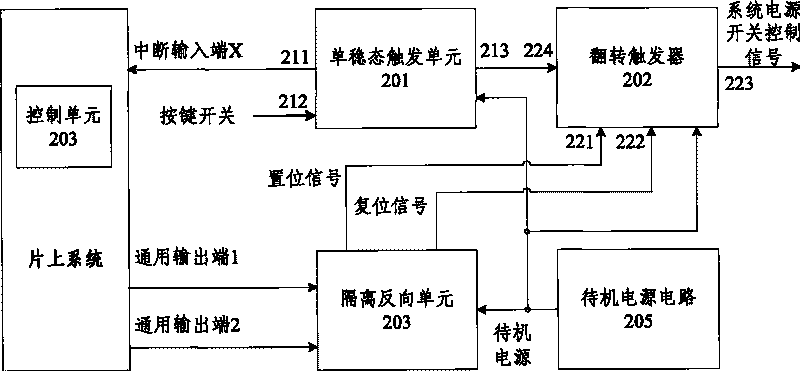

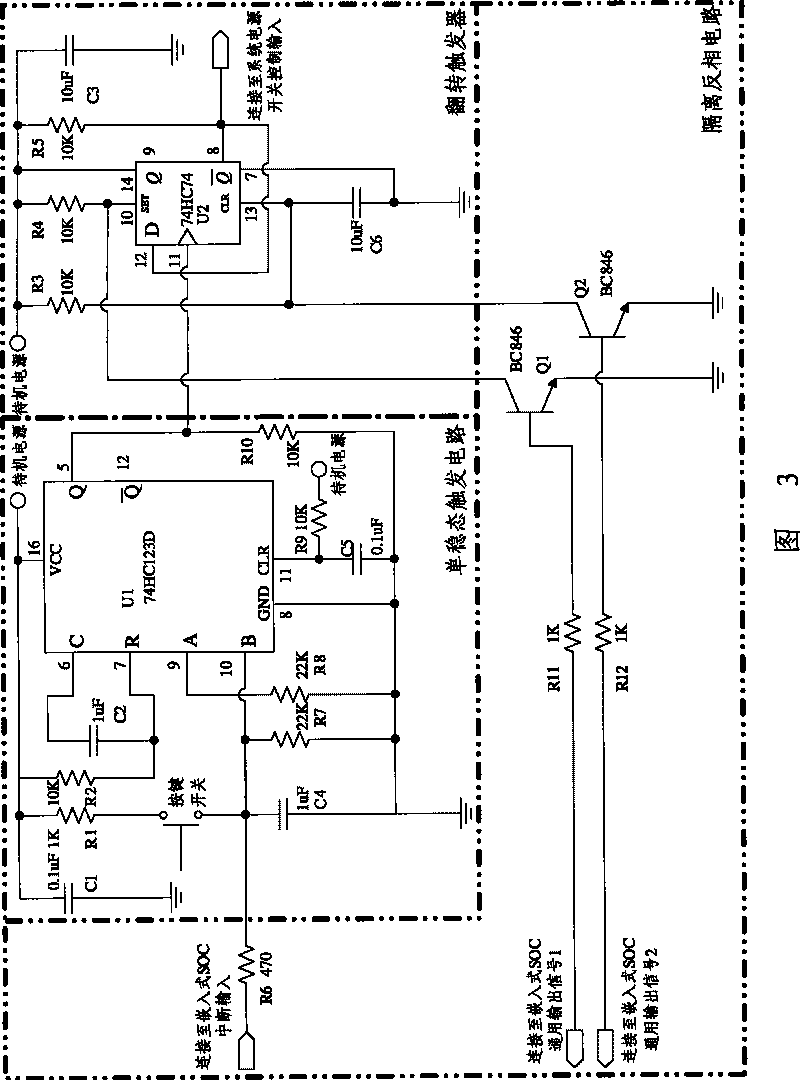

Safe switching apparatus and switching method for system on chip

ActiveCN101335514BNot lostAvoid technical issues that corrupt the hard disk file systemElectronic switchingStandby powerEngineering

Owner:北京神州龙芯集成电路设计有限公司

A preparation method of high temperature resistant modified fused zirconia and praseodymium yellow material

The invention relates to a preparation method of high-temperature-resistant modified fused zirconia and praseodymium yellow pigment. Grain composition of fused zirconia is controlled within a reasonable range through grinding and homogenizing treatment firstly, the specific surface area of fused zirconia is increased, then a proper reactive adhesive is added to be fixedly combined with fused zirconia, the reaction activity of fused zirconia is increased, so that modified fused zirconia with the specific surface area and the reaction activity close to those of chemical zirconium is obtained, the temperature resistance of ceramic pigment prepared from high-temperature-resistant modified fused zirconia is close to that of high-temperature-resistant ceramic pigment prepared from the chemical zirconium, the ceramic pigment can completely replace the high-temperature-resistant ceramic pigment prepared from the chemical zirconium, the application bottleneck of fused zirconia in the field of high-end ceramic pigment is broken through, and the production cost of the high-temperature-resistant ceramic pigment is reduced.

Owner:SANXIANG ADVANCED MATERIALS

Up-conversion resin based on polydimethylsiloxane and its preparation method and application

ActiveCN105647519BImprove conversion efficiencyUp-conversion efficiency reachesElectrolysis componentsOrganic chemistryMass ratioSilanes

The invention discloses an up-conversion resin based on polydimethylsiloxane and its preparation method and application; in a nitrogen atmosphere, a silane crosslinking agent and a dimethylsiloxane monomer are mixed at a ratio of 1:10 to Mixed at a mass ratio of 30; then vacuum treated and kept at 100°C for 2 h; then naturally cooled to form polysiloxane; then, under a nitrogen atmosphere, polysiloxane was placed in an organic solvent containing a photosensitizer and a luminescent agent , soaked for 18 to 30 hours, taken out and dried to obtain a solid up-conversion two-component system based on polysiloxane. The present invention discloses for the first time the preparation method of a solid-state up-conversion resin using PDMS as a matrix, and uses the green-to-blue light generated by the solid-state up-conversion resin to convert the solution-state up-conversion system into a solid-state material, which has high up-conversion efficiency and can be used in photolysis It has potential application value in hydrogen production and photosynthesis.

Owner:SUZHOU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com