Preparation method of up-conversion resin by taking polydimethylsiloxane as matrix

A polydimethylsiloxane and dimethylsiloxane technology, which is applied in the field of solid-state up-conversion two-component systems, can solve the problem of low conversion efficiency, triplet states of photosensitizers and luminescent agents that are easily quenched by oxygen, and inability to Meet practical application and other issues, achieve good compatibility and improve conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

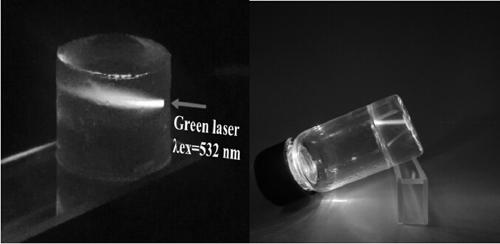

[0040] Example 1 Preparation of up-conversion resin (PdTPP / DPA / PDMS) based on polydimethylsiloxane

[0041] (1) In a nitrogen atmosphere, mix phenyltributanoximinosilane (crosslinking agent) and dimethylsiloxane monomer (DMS) at a ratio of 1:20 (mass ratio), vacuumize, and keep for 30 min. Then keep it at 100 °C for 2 h, take it out and cool it naturally to form a transparent polymer body (PDMS);

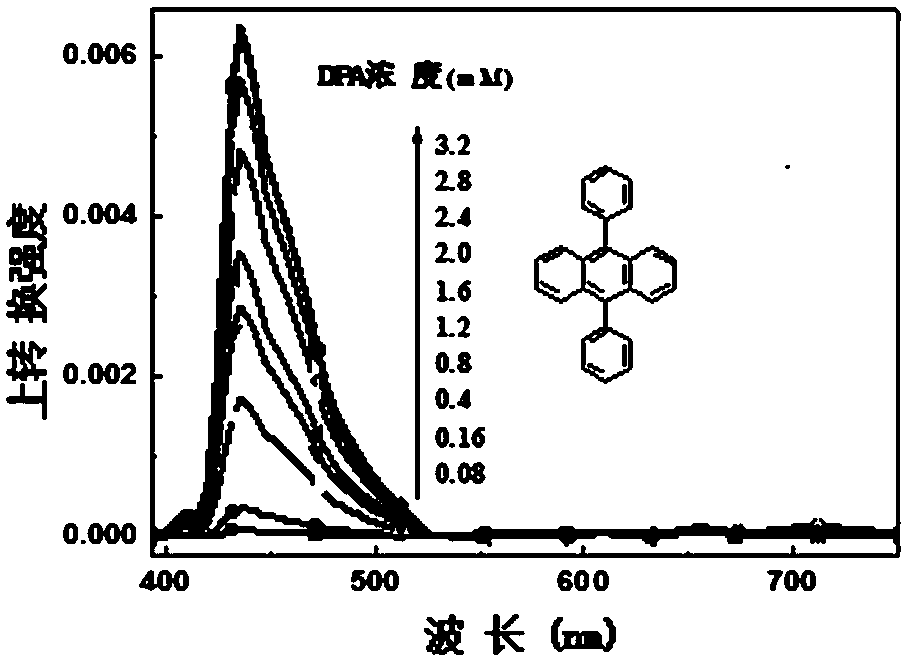

[0042] (2) First prepare photosensitizer (PdTPP) mother solution (concentration is 4×10 -5 mol / L), luminescent agent (DPA) mother solution (concentration is 1×10 -2 mol / L); then a certain amount of photosensitizer (PdTPP) solution and luminescent agent (DPA) solution were mixed and degassed to obtain a two-component up-conversion solution, and the solvent was spectrally pure toluene;

[0043] (3) Mix the PDMS polymer with the upconversion solution at a ratio of 1:1, place it under nitrogen protection for 24 h, take it out and dry it to form a transparent upconversion resin based...

Embodiment 2

[0048] Example 2 The application of the up-conversion resin based on polydimethylsiloxane in the synthesis of 7-hydroxycoumarin from coumarin

[0049] Coumarin solution configuration: in deionized water, add coumarin (concentration 2×10 -5 mol / L) and Pt / WO 3 Catalyst (concentration 10 mg / L), prepare 6 copies of the same solution (A~F) for standby.

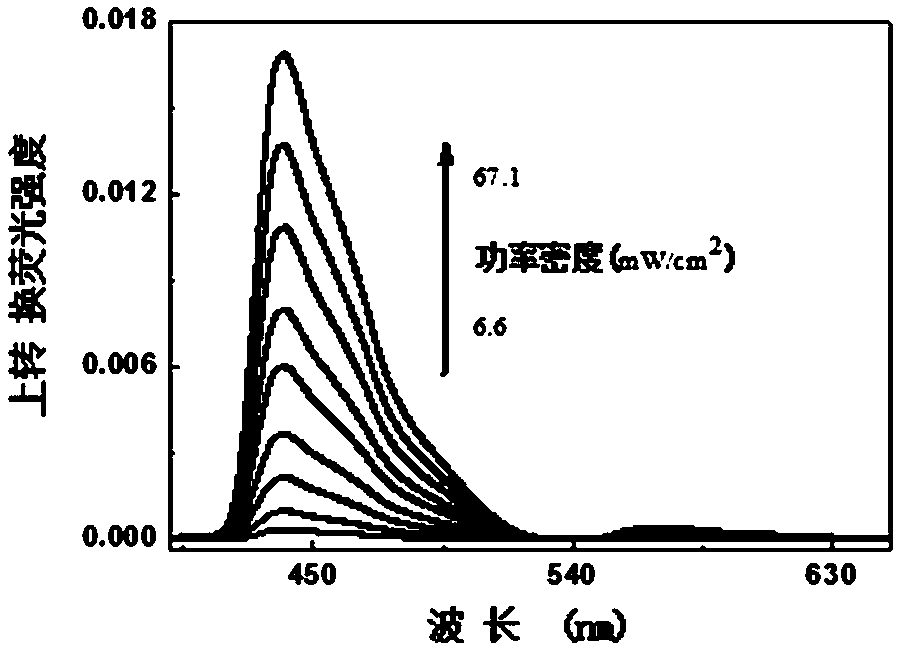

[0050] Up-conversion blue light irradiation: use 532 nm (power density 70 mW / cm 2 ) semiconductor laser, irradiate the solid up-conversion two-component system based on polysiloxane in Example 1 to produce blue up-conversion fluorescence, and use this up-conversion blue light to directly irradiate the above-mentioned coumarin solution (A~F) respectively, and irradiate The time is: Group A (0 min), Group B (20 min), Group C (40 min), Group D (60 min), Group E (80 min), Group F (100 min).

[0051] Fluorescence spectrum test of solution: such as Figure 5 , the coumarin solution is colorless, and the fluorescence peak of the solu...

Embodiment 3

[0052] Example 3 Application of up-conversion resin based on polydimethylsiloxane in photolysis of water for hydrogen production

[0053] according to Image 6 As shown in the device, ZnCdS nanoparticles were deposited on FTO glass as photoanode, platinum wire electrode as counter electrode, Ag / AgCl (0.1 M) as reference electrode to form a standard three-electrode cell (1.0 M of H 2 SO 4 As electrolyte, the solvent is deionized water). Under the excitation of a solid-state laser (excitation wavelength of 532 nm, power density of 60 mW cm -2 ), ZnCdS photoanode (E g = 2.35 eV) to absorb the blue light generated by the polysiloxane-based solid up-conversion two-component system in Example 1. The current is detectable by the electrochemical workstation, confirming that solid-state upconversion of blue light can drive photoelectrochemical reactions, such as Figure 7 As shown, the up-conversion resin based on polydimethylsiloxane can generate a photocurrent value of 0.9 μA, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com