Metal-organic framework material, and molding method and application thereof

A metal-organic framework and molding method technology, applied in the field of environmental science and engineering, can solve the problems of difficult recovery, restrict the application of MOFs, easy loss, etc., and achieve the effects of not easy loss, good removal effect, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 0.5g, 5g and 20g of MIL-68(Al) powder into 100mL water respectively, heat the water bath to 90℃ and stir to disperse, then slowly add 1g sodium alginate, keep the temperature at 90℃ until the sodium alginate is completely dissolved, and cool to room temperature , To obtain a colloidal liquid; use a syringe to drop the colloidal liquid into a 4 wt% calcium chloride solution, let stand for 2 hours, filter, wash with water, and dry to obtain metal organic framework material particles. Labeled as particle 1, particle 2, and particle 3 in sequence.

Embodiment 2

[0042] In parallel 2 groups, respectively add 5g of MIL-68(Al) powder into 100mL water, heat the water bath to 90℃ and stir to disperse, then slowly add 0.3g and 20g sodium alginate respectively, keep the temperature at 90℃ until the sodium alginate is completely dissolved, and cool to At room temperature, the gelatinous liquid is obtained; use a syringe to drop the gelatinous liquid into the calcium chloride solution, in which 0.3g sodium alginate group is added dropwise to 1wt% calcium chloride solution, 20g sodium alginate group is added dropwise to 6wt % Calcium chloride solution, let stand for 2 hours, filter, wash with water, and filter dry to obtain metal organic framework material particles. Labeled as particle 4 and particle 5 in sequence.

Embodiment 3

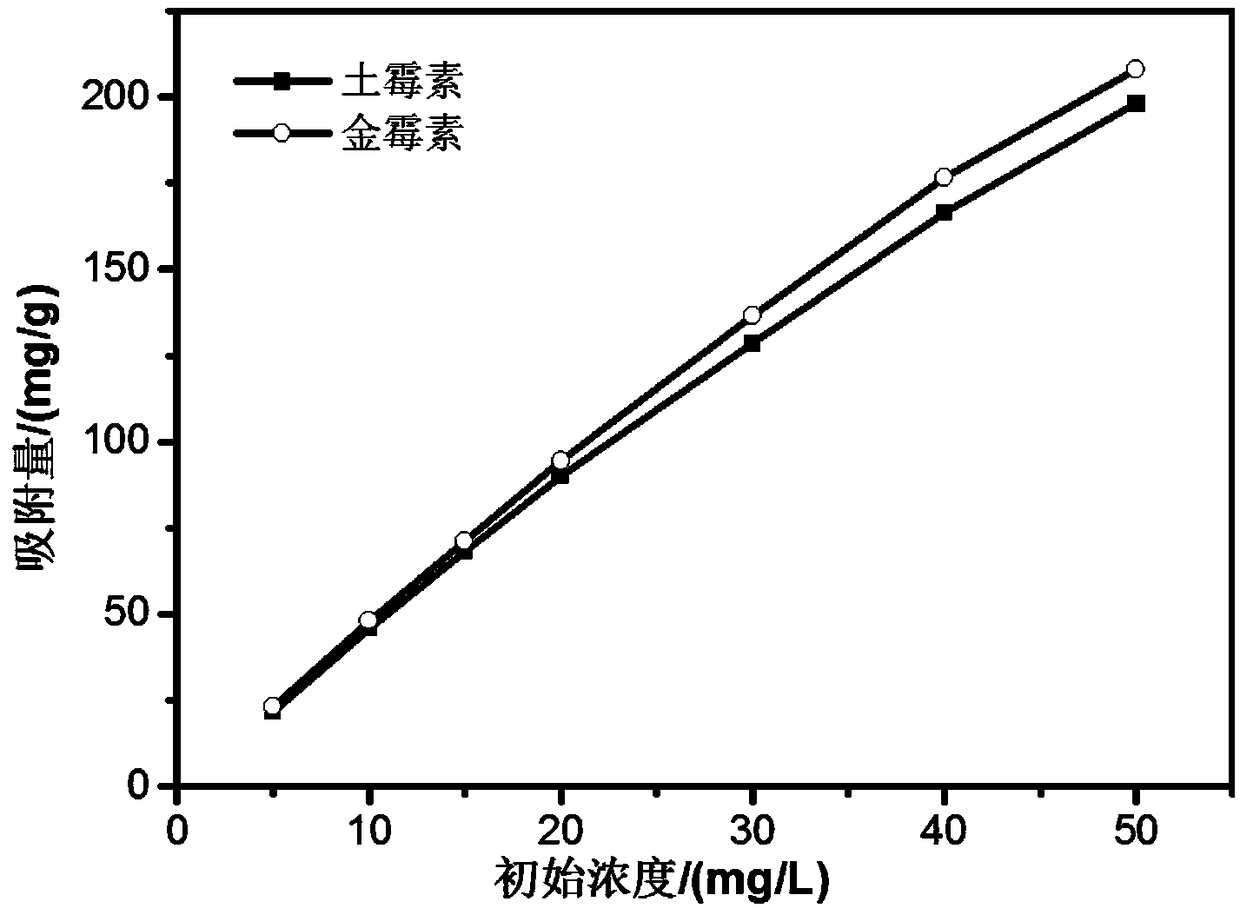

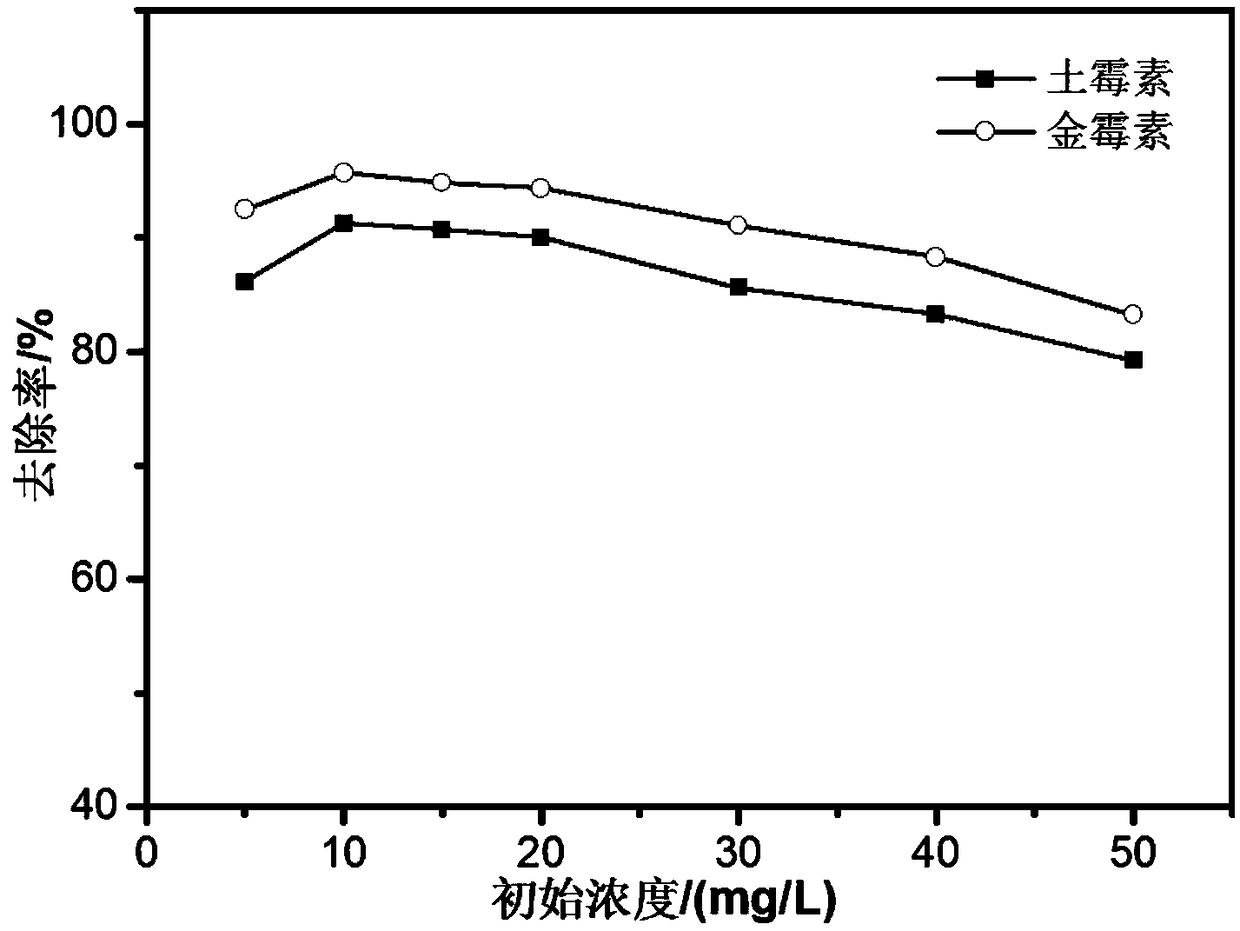

[0043] Example 3: Adsorption test

[0044] Prepare chlortetracycline and oxytetracycline solutions with concentration gradients of 5, 10, 15, 20, 30, 40, and 50 mg / L, each with a volume of 100 mL, and 0.464 g of metal organic framework is added to each solution Material particle 2 (particle moisture content is 90%), shake and adsorb for 6 hours at 25°C.

[0045] Characterization methods and results:

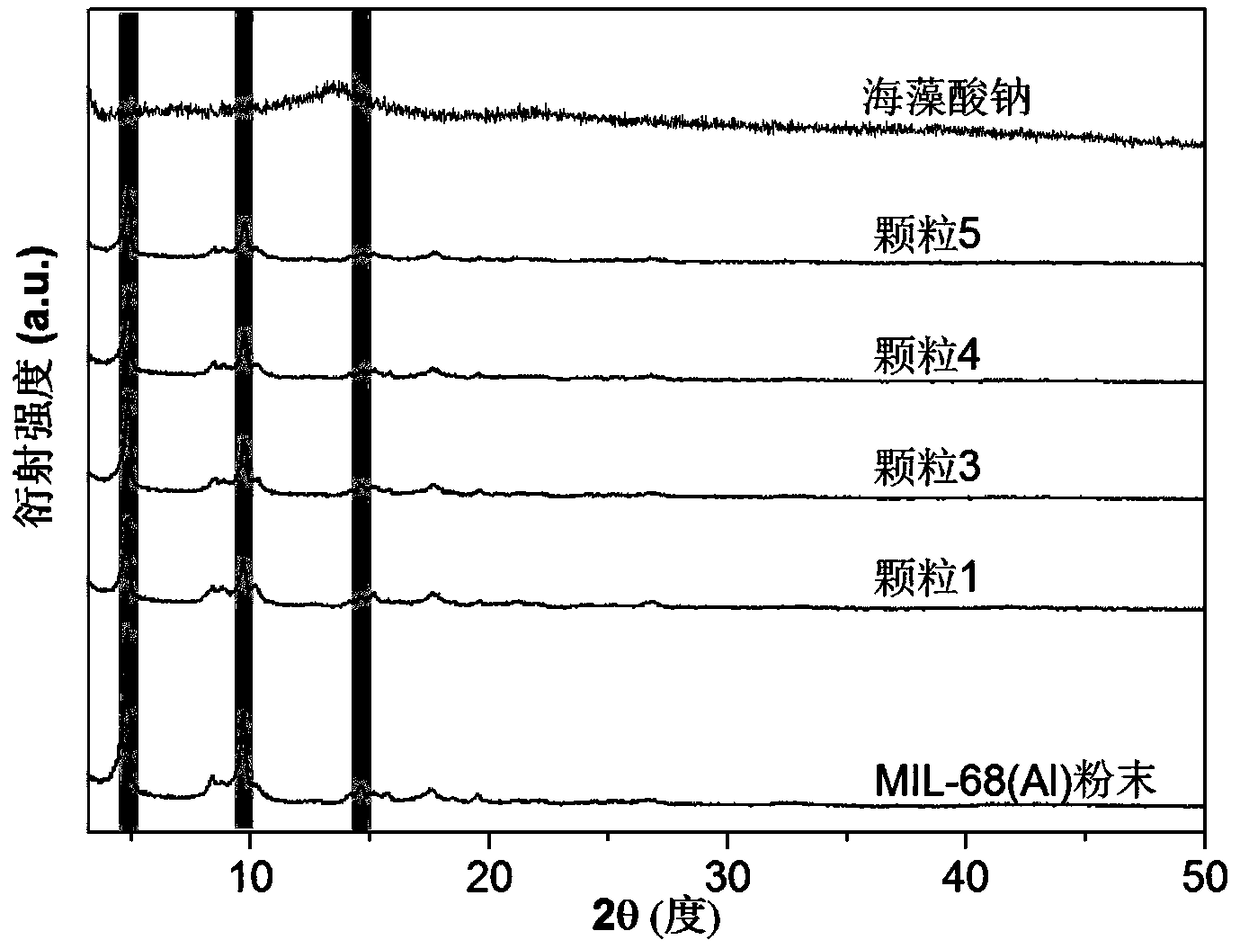

[0046] (1) XRD analysis results

[0047] The materials prepared in Example 1 and Example 2 of the present invention were characterized by the Empyrean X-ray diffractometer produced by PANalytical, the operating conditions were: copper target, 40KV, 40mA, step length 0.02626 degrees, scanning speed 8.109 Seconds / step. The preparation of MIL-68(Al) powder refers to the literature (Synthesis of aluminum-based MOF / graphite oxide composite and enhanced removal of methyl orange[J].Journal of Alloys&Compounds,2017.). The result is figure 1 ,From figure 1 It can be seen that the XRD character...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com