A system for coupling and drying slurry thermal insulation materials by using waste heat of flue gas

A technology for thermal insulation materials and flue gas waste heat, which is applied in the direction of static material dryers, solid material drying, local agitation dryers, etc. It can solve the problems of poor thermal insulation effect, little use value, and huge heat loss, etc. , to achieve the effect of improving heat conversion efficiency, rapid and convenient application, and solving application bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

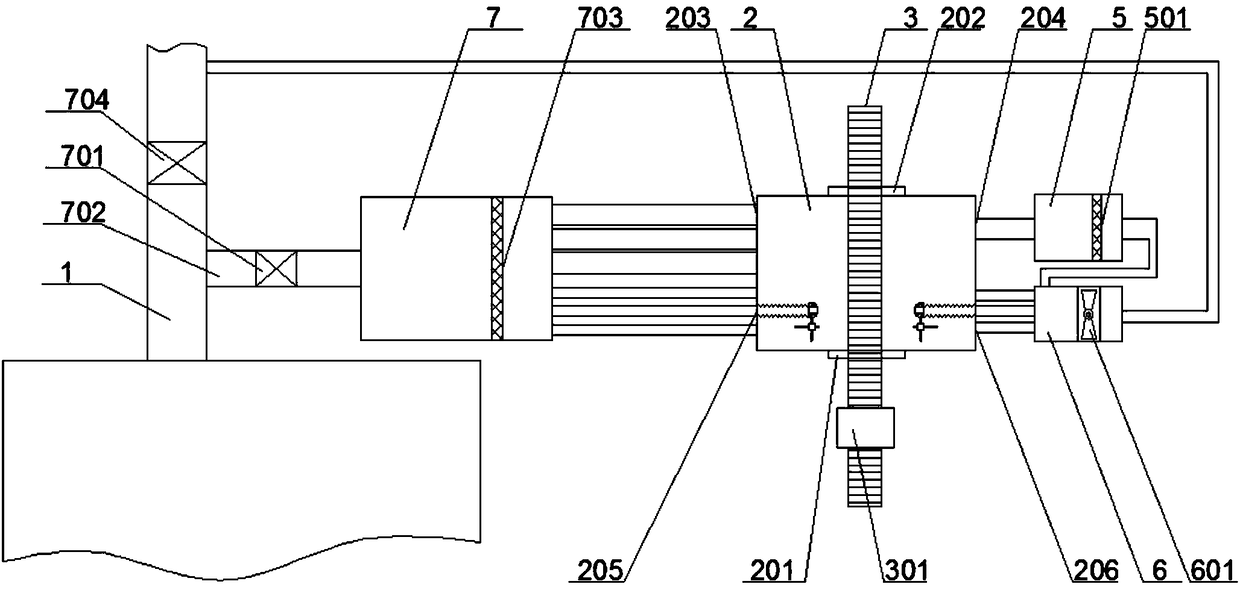

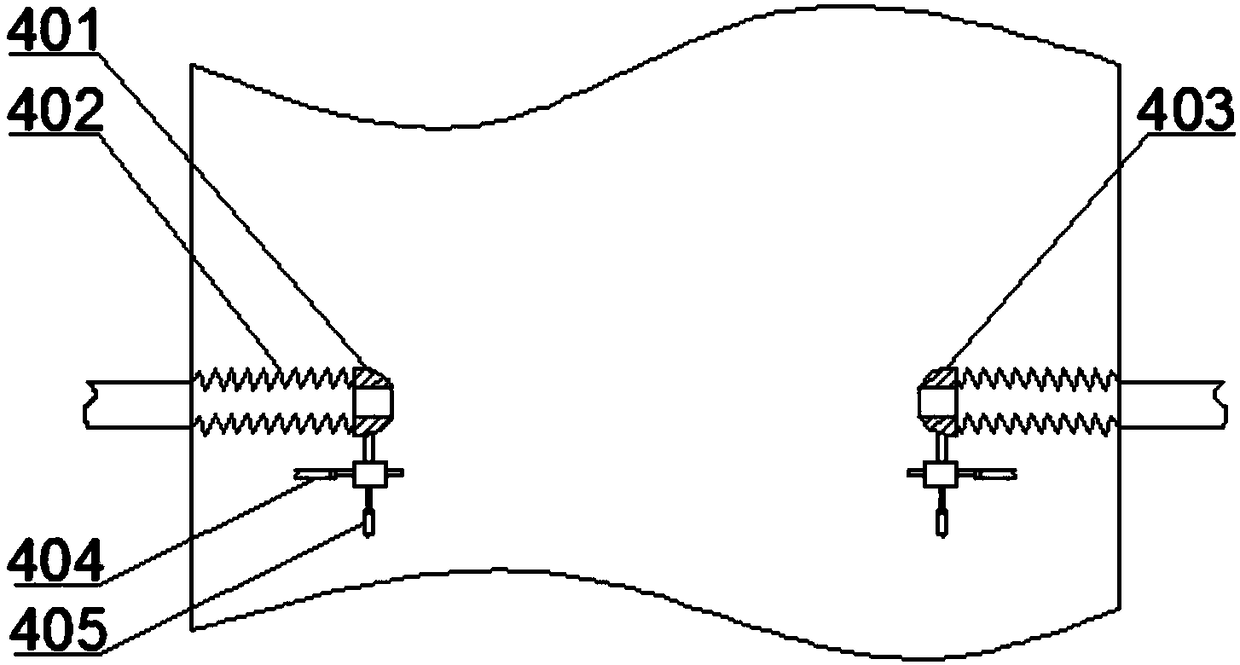

[0020] The invention relates to a system for coupling and drying slurry-like thermal insulation materials by using waste heat of flue gas, which includes a flue gas conveying mechanism and a heat recovery mechanism that communicate with a flue 1 and are sequentially connected front and rear, and the heat recovery mechanism includes a drying unit , a dust removal unit and a return air unit, the drying unit includes a drying cavity 2 with an inlet door 201 and an outlet door 202 on both sides, and a first air inlet 203 and a second air inlet 205 are provided at the front end of the drying unit Connected with the flue gas conveying mechanism, the rear end is provided with a first air outlet 204 and a second air outlet 206 connected with the dust removal unit and the return air unit, and a pipeline internal heating system is arranged between the second air inlet 205 and the second air outlet 206 , the drying unit is provided with a conveying track 3 with a carrying trolley 301 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com