Welding materials for butt welding of transition layers of titanium clad steel plate and welding method of welding materials

A technology of welding materials and composite plates, which is applied in the directions of welding/welding/cutting objects, welding/cutting media/materials, welding media, etc., can solve the bottleneck of welding application of titanium steel composite plates, and it is difficult to directly and widely use it on offshore platforms field and other issues, achieve high strength and toughness, and solve the effect of application bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

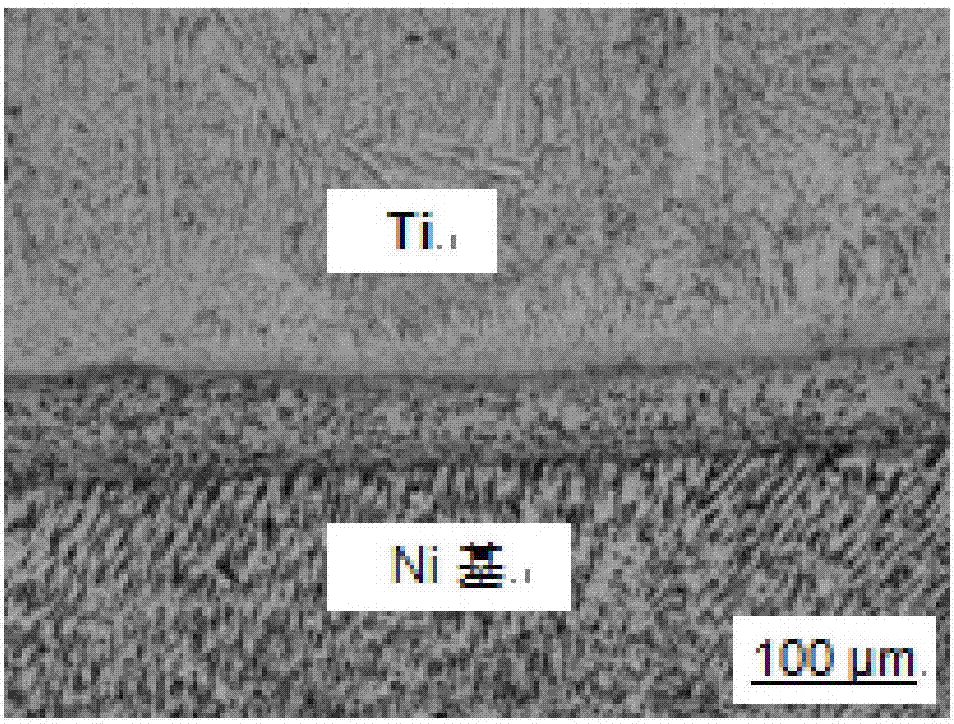

[0013] The invention relates to a welding material for fusion-welding butt joint transition layers of titanium-steel composite plates. Including the surfacing layer, the near-titanium layer, the welding material for the underlying layer, a component of the welding material for the surfacing layer and the near-titanium layer includes the following components by weight percentage: C: 0.011%, Si: 0.32%, Mn: 4.0 %, P: 0.01%, S: 0.01%, Cr: 17.0%, Mo: 16.0%, Cu: 2.0%, Fe: 5.0%, the balance is Ni, the bottom layer welding material is Ni≥99.9%, the above components The sum of weight percentages is 100%.

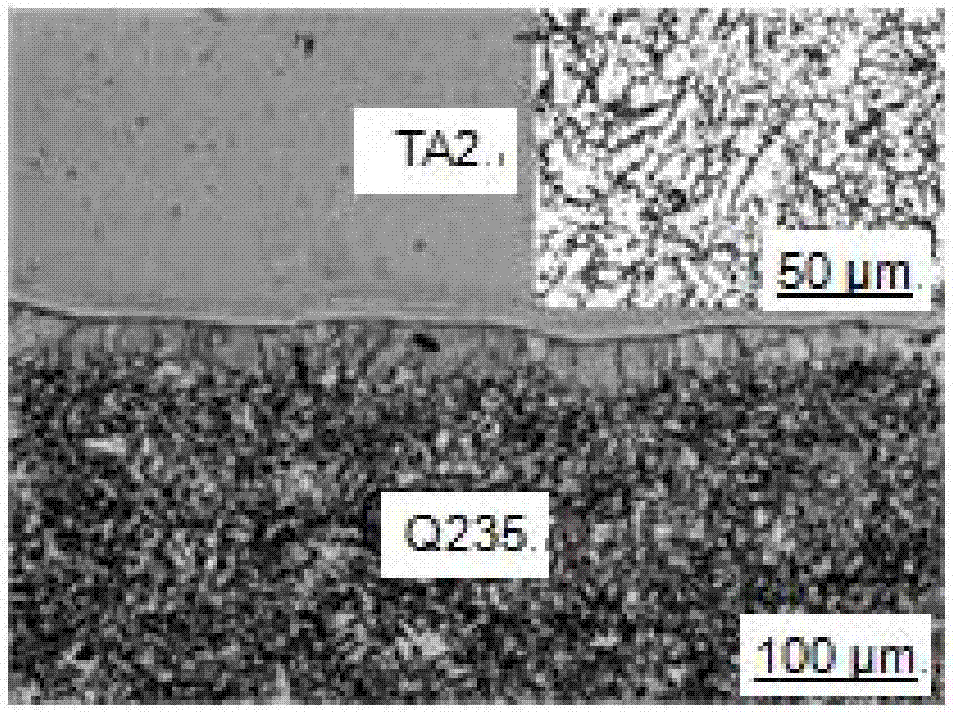

[0014] The parent material that the present invention adopts is TA2 / Q235 titanium-steel clad plate, and the concrete steps of welding method are as follows:

[0015] Step 1, groove design and cleaning

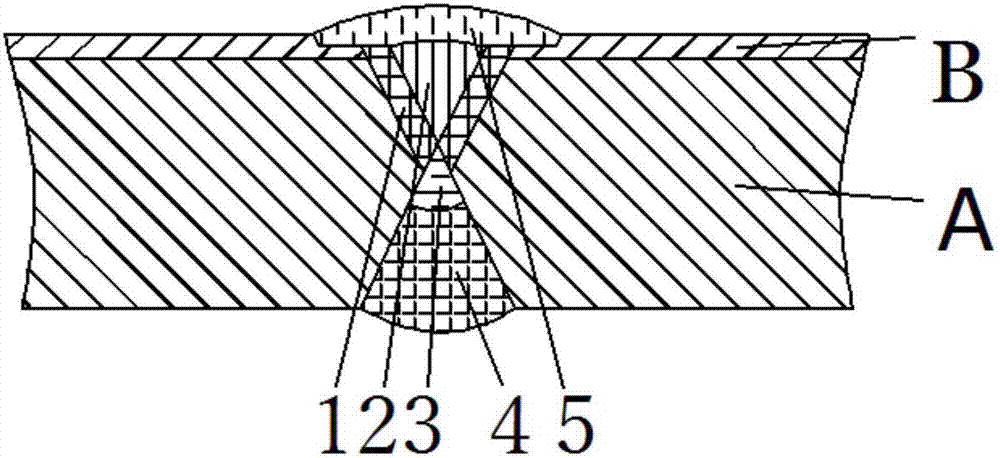

[0016] The design of the groove form of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com