Preparation method of high-temperature-resistant modified fused zirconia and praseodymium yellow pigment

A technology of fused zirconia and praseodymium yellow materials, which is applied in the field of inorganic materials, can solve the problems of easy fading, poor temperature resistance, and poor temperature resistance performance, and achieve the effects of overcoming application bottlenecks, reducing production costs, and meeting use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

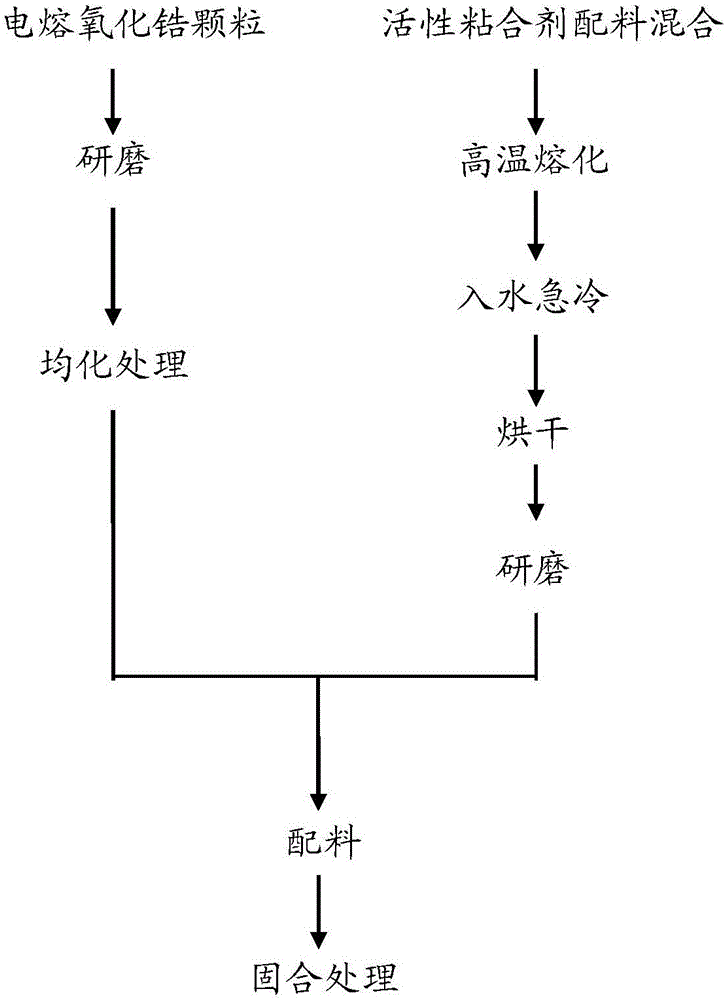

[0023] Specifically, please refer to figure 1 As shown, the preparation method of the high temperature resistant modified fused zirconia of the embodiment of the present invention includes:

[0024] Grinding the fused zirconia particles into zirconia powder with a particle size of 3-5 μm;

[0025] The alkali metal and alkaline earth metal are mixed according to the weight ratio of 6~7:4~5, and then melted at high temperature, quenched in water, washed to neutrality, dried, and ground to obtain an active adhesive with a particle diameter of 1-1.5 μm , the high-temperature melting temperature is 1200-1400°C, the alkali metal is lithium, sodium or a lithium-sodium mixture, and the alkaline earth metal is beryllium, magnesium or a magnesium-calcium mixture;

[0026] Mix the zirconia powder and the active binder, the amount of the active binder is 0.05-0.3wt% of the total amount of the mixture, and then treat it at 150-300°C and 1-3MPa for 10-20h to obtain a durable High temperat...

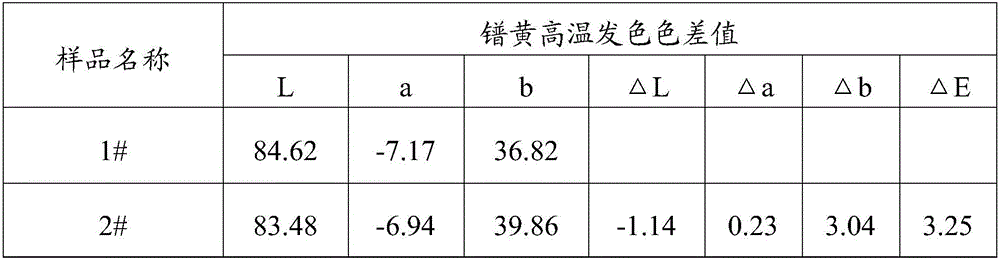

Embodiment 1

[0042] Grinding the fused zirconia particles into zirconia powder with a particle size of 3-5 μm;

[0043] Lithium and magnesium are mixed according to the weight ratio of 3:2, followed by high-temperature melting, rapid cooling in water, washing to neutrality, drying, and grinding to obtain an active adhesive with a particle diameter of 1-1.5 μm. The high-temperature melting temperature is 1200°C;

[0044] The zirconia powder and the active binder are mixed, and the amount of the active binder is 0.3wt% of the total amount of the mixture, and then treated at 150°C and 1MPa for 10h to make the zirconia powder and the active binder completely bonded together to increase the reactivity of fused zirconia to obtain modified fused zirconia;

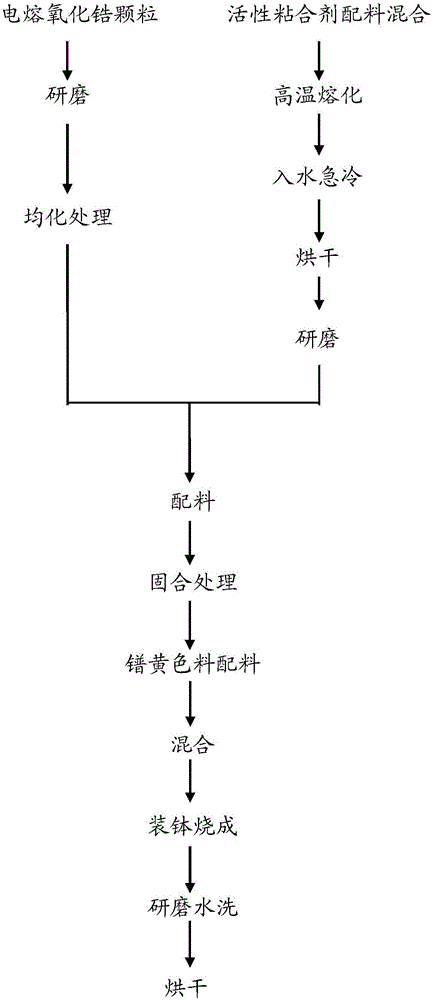

[0045]Fully mix the modified fused zirconia and other auxiliary raw materials of the praseodymium yellow material, put them in a bowl and heat them at a heating rate of 150°C / h for calcination, when the calcination temperature reaches 950°C, ...

Embodiment 2

[0047] Grinding the fused zirconia particles into zirconia powder with a particle size of 3-5 μm;

[0048] Sodium and beryllium are mixed according to the weight ratio of 6:5, followed by high-temperature melting, rapid cooling in water, washing to neutrality, drying, and grinding to obtain an active adhesive with a particle diameter of 1-1.5 μm. The high-temperature melting temperature is 1400°C;

[0049] The zirconia powder and the active binder are mixed, and the amount of the active binder is 0.2wt% of the total amount of the mixture, and treated at 300°C and 3MPa for 20h, so that the zirconia powder and the active binder are completely bonded. Together, improve the reactivity of fused zirconia to obtain modified fused zirconia;

[0050] Fully mix the modified fused zirconia and other auxiliary raw materials of the praseodymium yellow material, put them in a bowl and heat them at a heating rate of 180°C / h for calcination, when the calcination temperature reaches 1050°C, k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com