Preparation method for praseodymium yellow pigment

一种镨黄色料、电熔氧化锆的技术,应用在化学仪器和方法、染色冲洗、纤维状填料等方向,能够解决耐温性差、易褪色、耐温性能变差等问题,达到降低生产成本、克服应用瓶颈、不易褪色的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

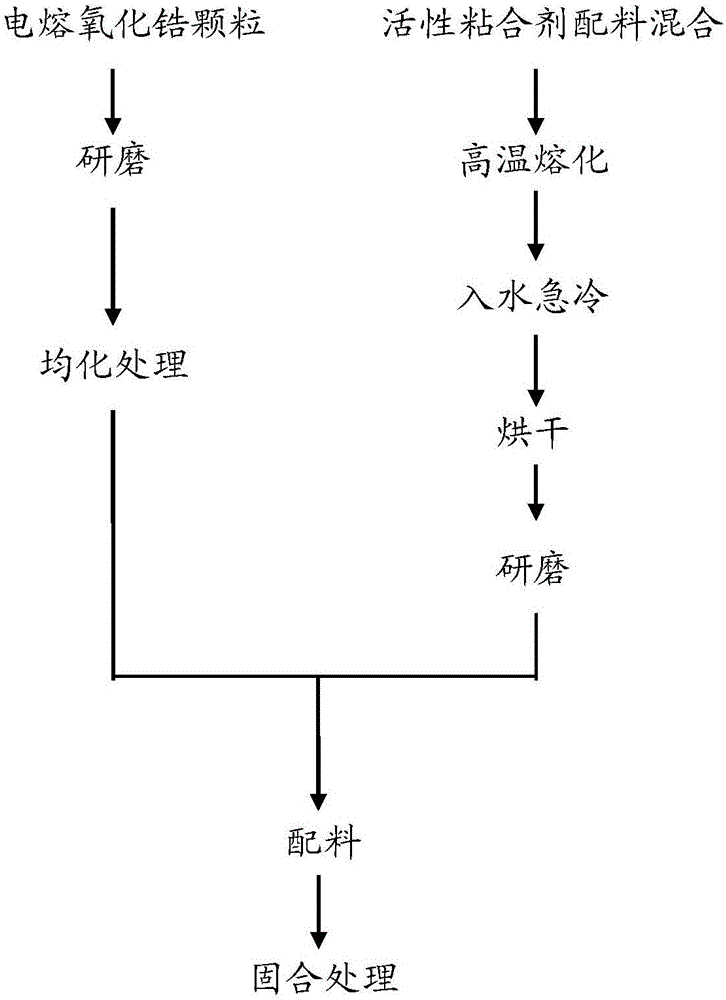

[0017] Specifically, please refer to figure 1 As shown, the preparation method of the modified fused zirconia in the embodiment of the present invention includes:

[0018] Grinding the fused zirconia particles into zirconia powder with a particle size of 3-5 μm and then homogenizing;

[0019] The lithium-sodium mixture and the magnesium-calcium mixture are mixed according to the weight ratio of 7:4, followed by high-temperature melting, water quenching treatment, water washing to neutrality, drying, and grinding to obtain an active adhesive with a particle diameter of 1-1.5 μm. The high-temperature melting temperature is 1300°C;

[0020] Mix the zirconia powder and the active binder, the amount of the active binder is 0.05wt% of the total amount of the mixture, and treat it at 200°C and 2MPa for 10h, so that the zirconia powder and the active binder are completely bonded. Together, they increase the reactivity of fused zirconia to obtain modified fused zirconia.

[0021] In...

specific Embodiment

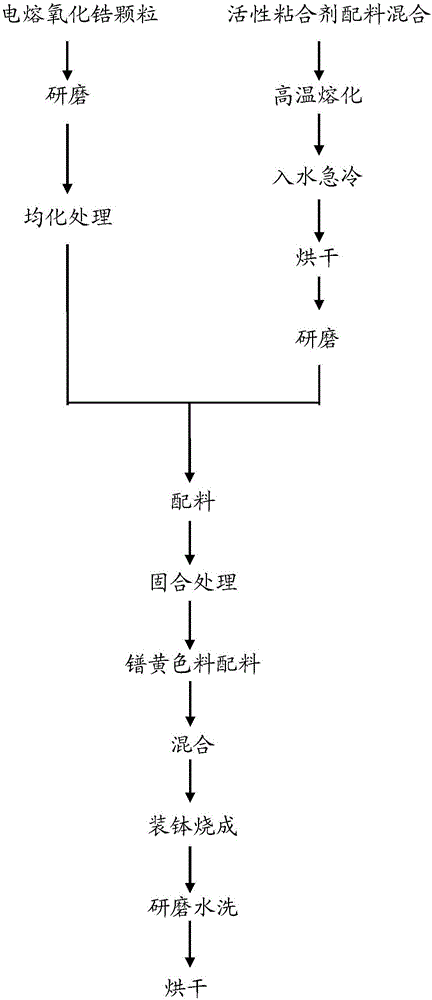

[0031] Grinding the fused zirconia particles into zirconia powder with a particle size of 3-5 μm and then homogenizing;

[0032] The lithium-sodium mixture and the magnesium-calcium mixture are mixed according to the weight ratio of 7:4, followed by high-temperature melting, water quenching treatment, water washing to neutrality, drying, and grinding to obtain an active adhesive with a particle diameter of 1-1.5 μm. The high-temperature melting temperature is 1300°C;

[0033] Mix the zirconia powder and the active binder, the amount of the active binder is 0.05wt% of the total amount of the mixture, and treat it at 200°C and 2MPa for 10h, so that the zirconia powder and the active binder are completely bonded. Together, improve the reactivity of fused zirconia to obtain modified fused zirconia;

[0034] Fully mix the modified fused zirconia and other auxiliary raw materials of the praseodymium yellow material, put them in a bowl and heat them at a heating rate of 160°C / h for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com