Novel efficient and low-resistance compound antibacterial air filtering material

An air filtration material and high-efficiency technology, applied in the direction of filtration and separation, synthetic resin layered products, layered products, etc., can solve the problems of non-sterilization, high air resistance, high breaking strength, low air resistance, small particle size, The effect of high surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

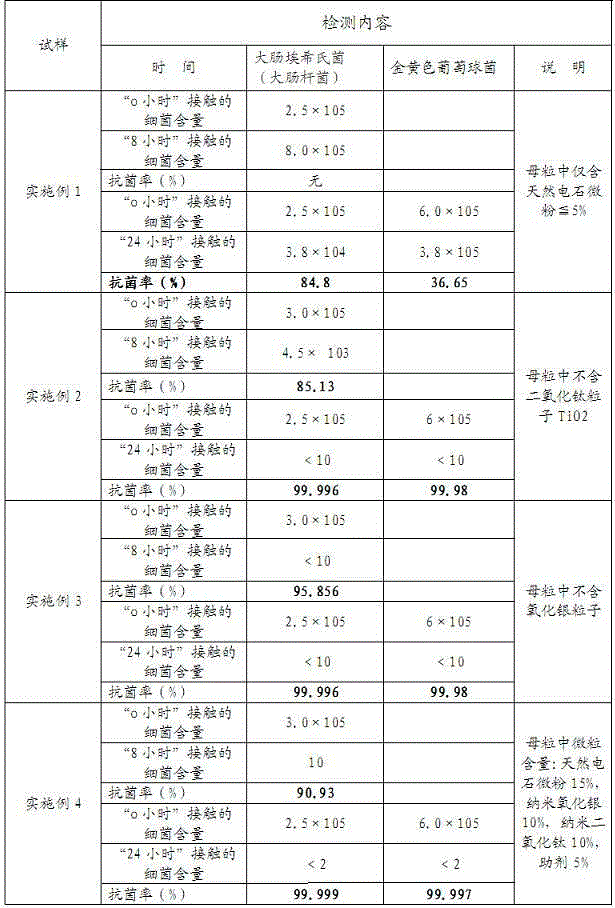

Embodiment 1

[0021] The new high-efficiency and low-resistance composite antibacterial air filter material of the present invention includes a bottom layer of PET\PA two-component filament fiber and an antibacterial masterbatch\PP fiber surface layer, and the two layers are self-adhesively bonded by double nozzles;

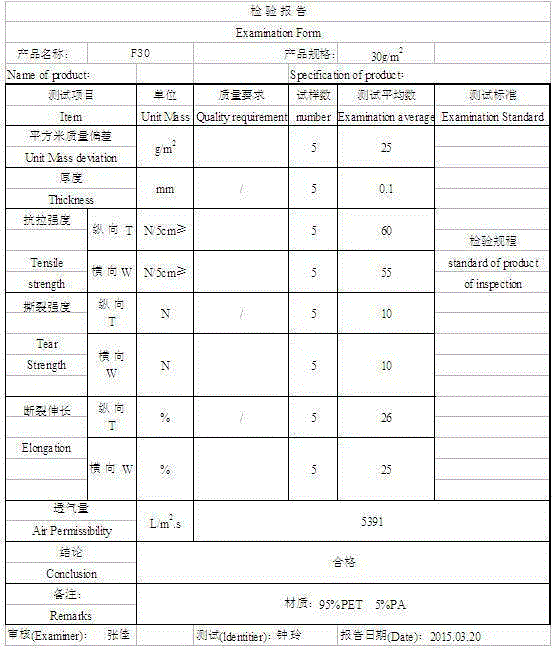

[0022] In the PET\PA two-component filament fiber, PET is 95% and PA is 5%, and the PET / PA two-component filament fiber requires 20-25g / ㎡;

[0023] The antibacterial masterbatch / PP fiber accounts for 2-2.5% of the PP basic raw material, wherein the antibacterial masterbatch includes the following components by weight:

[0024] pp resin chip 90% melt flow rate ≧ 230 ℃, 2.0kg (sin10)

[0025] Natural calcium carbide powder 5% particle size 0.1~0.3 microns

[0026] Auxiliary 5%

Embodiment 2

[0028] Antibacterial masterbatch\PP fiber, antibacterial masterbatch includes the following components by weight:

[0029] pp resin chip 60% melt flow rate ≧ 230 ℃, 2.0kg (sin10)

[0030] Natural calcium carbide powder 15% particle size 0.1~0.3 microns

[0031] Silver oxide particles 20% particle size 20~40nm

[0032] Auxiliary 5%

[0033] All the other as embodiment 1

Embodiment 3

[0035] Antibacterial masterbatch\PP fiber, antibacterial masterbatch includes the following components by weight:

[0036] pp resin chip 60% melt flow rate ≧ 230 ℃, 2.0kg (sin10)

[0037] Natural calcium carbide powder 15% particle size 0.1~0.3 microns

[0038] Titanium dioxide particles 20% particle size 20~40 nanometers

[0039] Auxiliary 5%

[0040] All the other as embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com