Automatic cleaning method of sprinkled coal in belt conveyance

An automatic cleaning and belt transportation technology, which is applied in cleaning devices, underground transportation, transportation and packaging, etc., can solve problems such as equipment damage and belt roadway pollution, and achieve the effects of reducing equipment wear, ensuring civilized hygiene, and saving labor resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

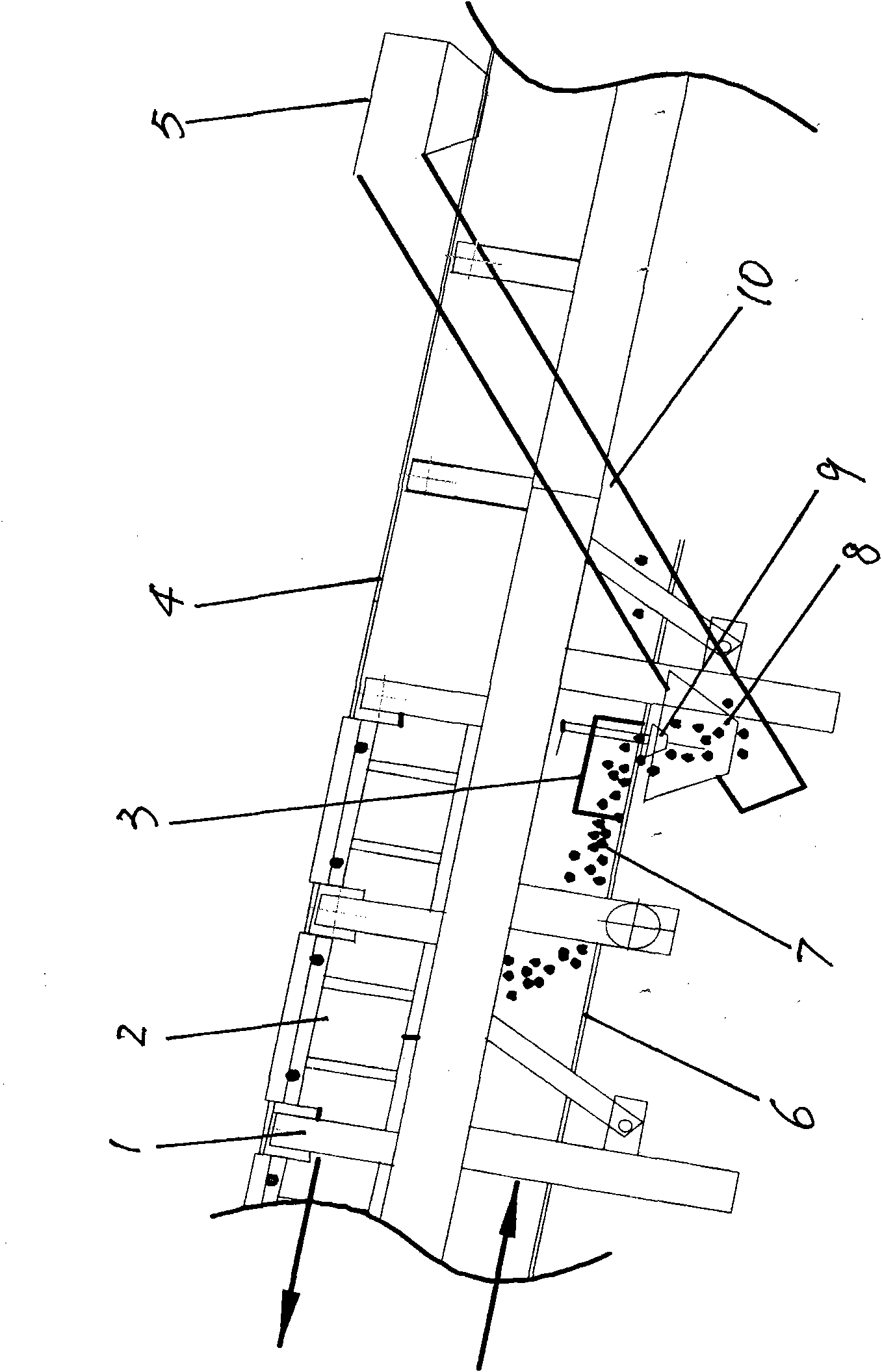

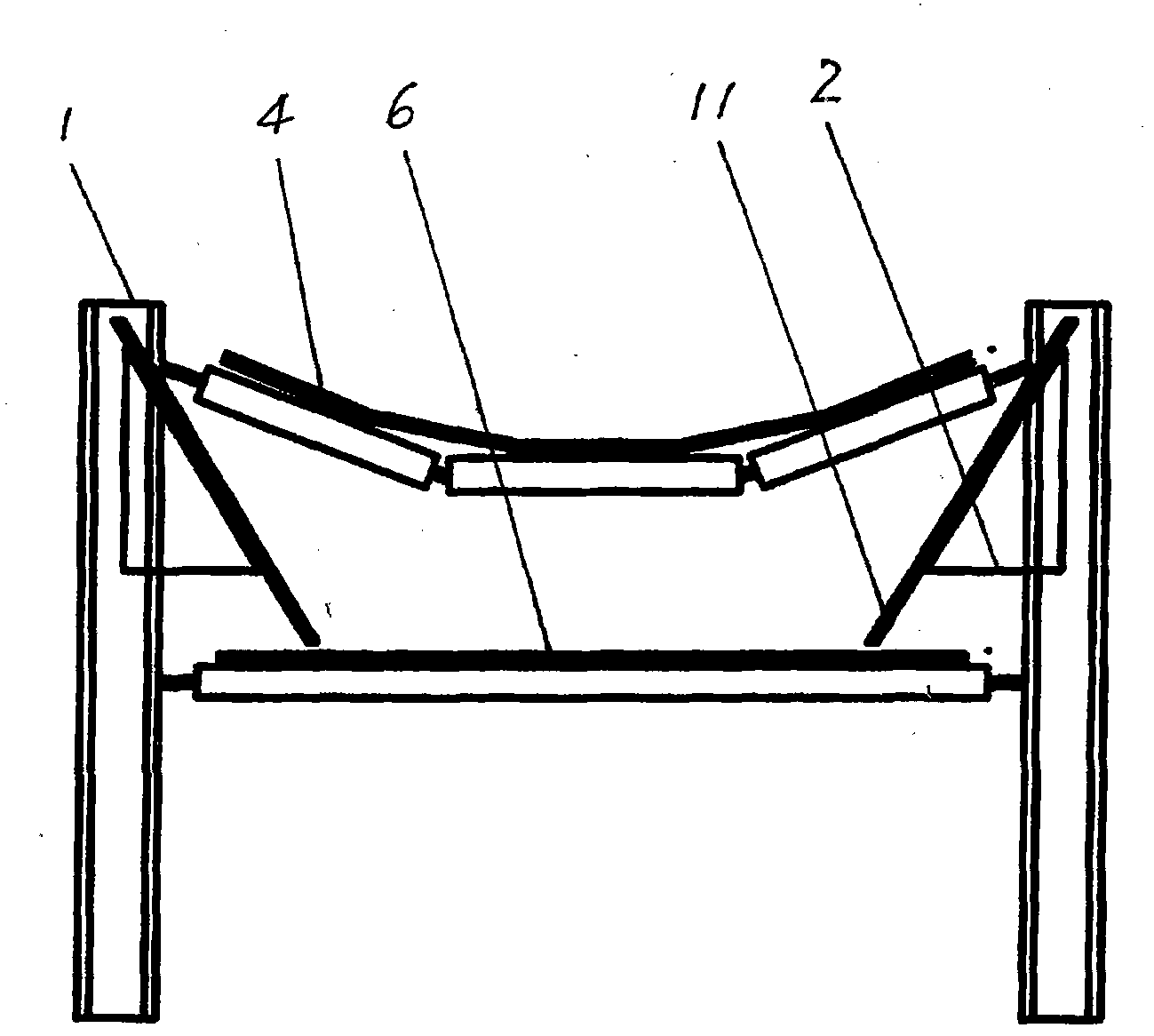

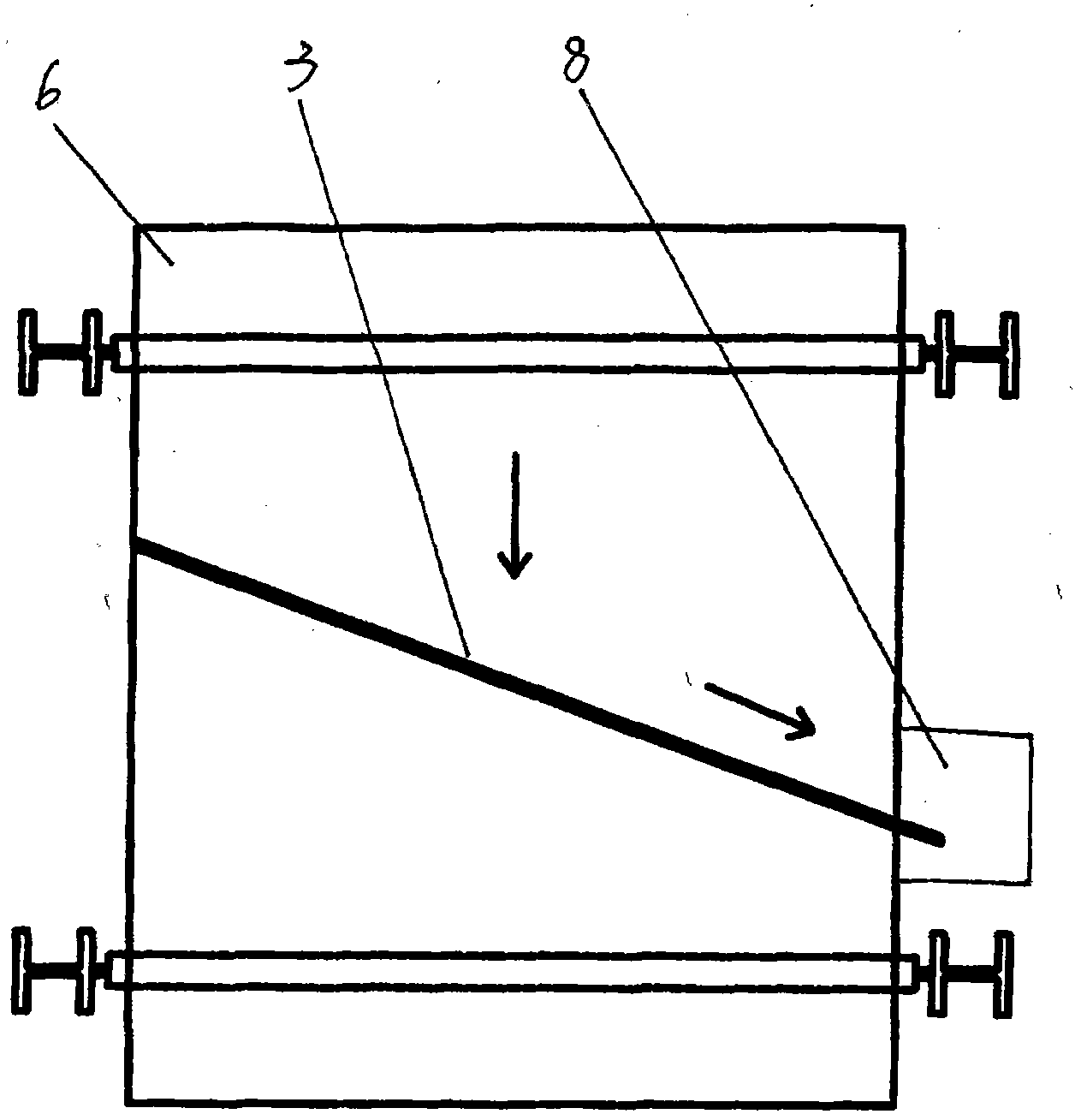

[0011] as attached figure 1 , 2 As shown, first install the coal retaining plate 2 on both sides of the belt conveyor frame 1 and between the upper and lower belts 4 and 6, the lower end of the coal retaining plate 2 is slightly inclined inwardly, and the upper end of the coal retaining plate 2 is about 200mm higher than the upper belt 4. About 10mm away from the edge of the upper belt 4, the lower end of the coal retaining plate 2 does not touch the upper surface of the lower belt 6, each coal retaining plate 2 is connected with a flexible rubber plate 11, the flexible rubber plate 11 is in contact with the upper surface of the lower belt 6, and rests on the lower belt 6; on the frame at the front 30 meters of the tail, below the upper belt 4, a coal sprinkling collection baffle 3 is installed in the vertical direction, and the lower edge of the coal sprinkling collection baffle 3 is slightly away from the lower belt 6 surface, and the coal sprinkling is collected The instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com