Organosilicon resin composition

A technology of resin composition and silicone, which is applied in the field of silicone resin composition, can solve problems such as large curing shrinkage rate and internal stress, high curing temperature, and long curing time, and achieve low curing shrinkage, short curing time, and excellent The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a silicone resin composition, the preparation steps of which are as follows:

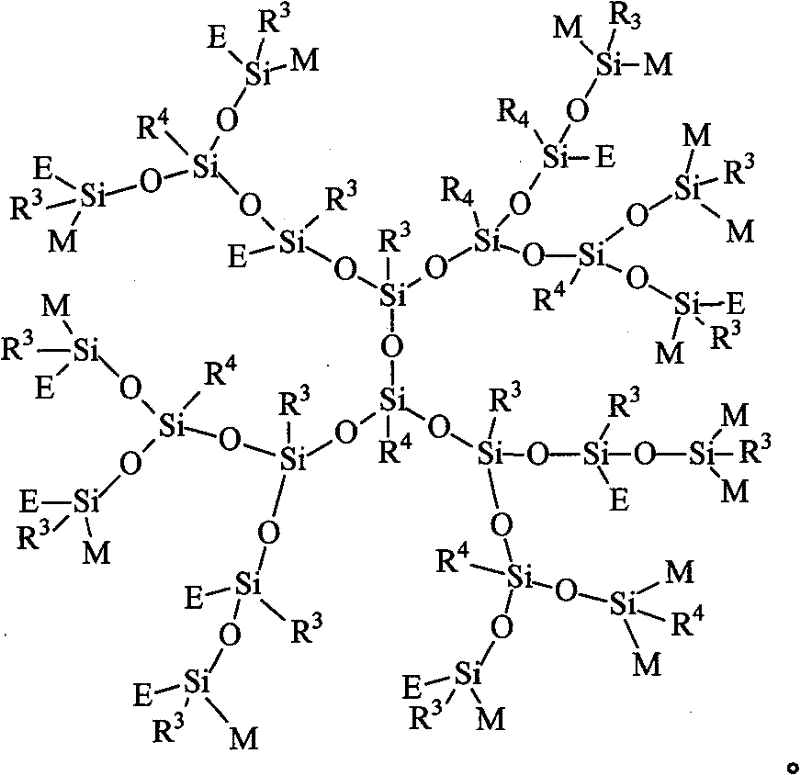

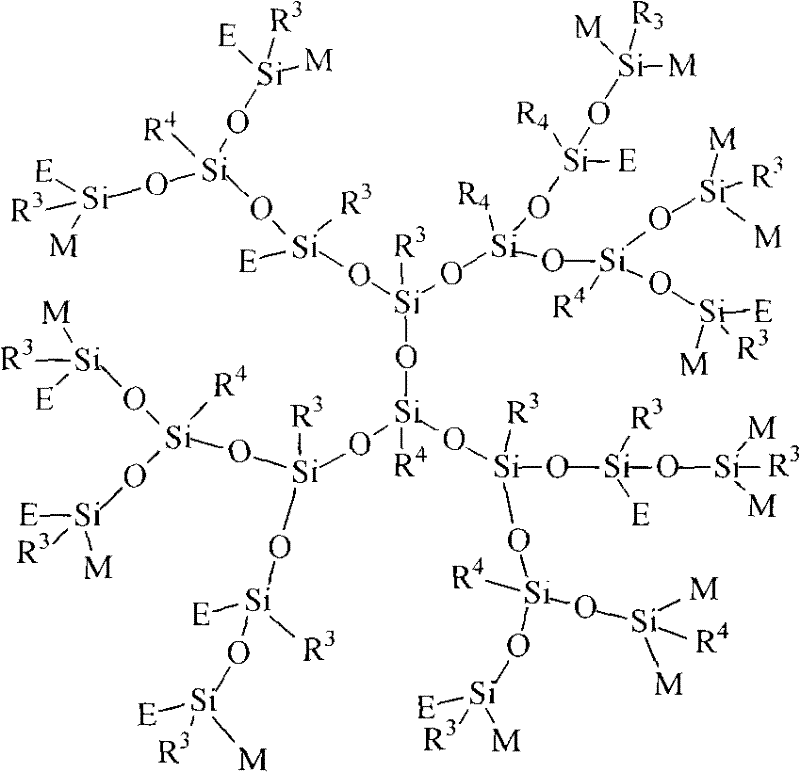

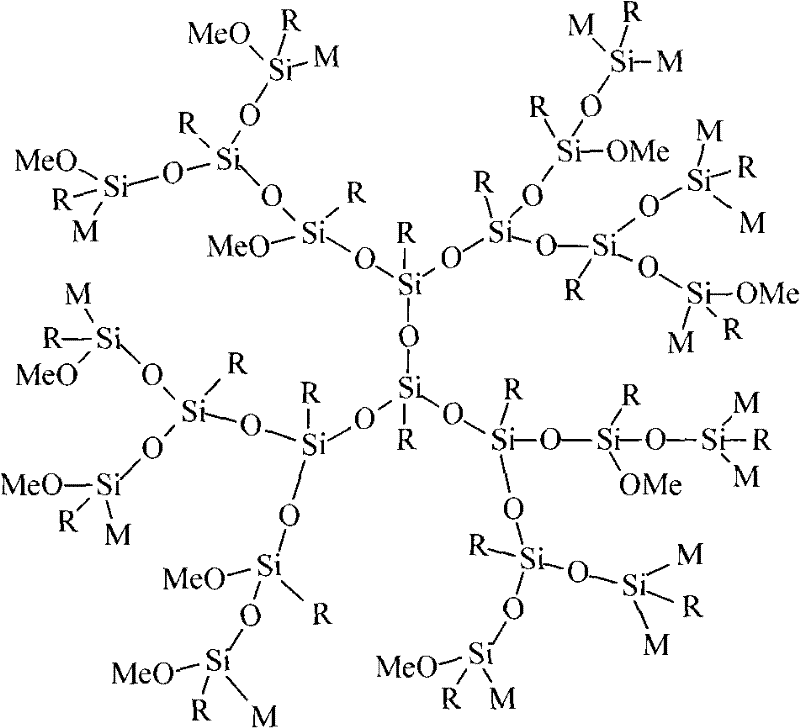

[0031] 1. Preparation of hyperbranched silicone resin containing epoxy functional groups

[0032] 1) Under stirring conditions, after adding 45.00g gamma-glycidoxypropyltrimethoxysilane, 5.15g deionized water and 0.22g tetramethylammonium hydroxide (20% aqueous solution) into the there-necked flask, at 40 Reflux at constant temperature for 2 hours at °C to obtain solution A;

[0033] 2) Under stirring conditions, dissolve 31.07g of trimethylchlorosilane in a mixed solvent of 18.00mL of methanol and 36.00mL of pyridine to obtain solution B;

[0034] 3) Pour solution B into solution A at 60° C. under stirring conditions, and reflux at constant temperature for 6 hours, and obtain a crude product after vacuum distillation;

[0035] 4) After the crude product is dissolved in dichloromethane, the insolubles are filtered off, and after vacuum distillation and vacuum drying...

Embodiment 2

[0041] 1. Preparation of Silicone Base Resin

[0042] Add the mixed solution containing 77g of phenyltrichlorosilane, 60g of methyltrichlorosilane and 100g of toluene dropwise into a mixed solvent of 125g of deionized water and 200g of toluene, and reflux for 6h under heating conditions, then stand to separate layers, Let go of the acidic water in the lower layer; after the hydrolyzate is washed with warm water to neutrality, it is distilled under reduced pressure at 70°C, and part of the solvent is removed until the hydrolyzed solid content is 50%; then, 69g of tetraethyl orthosilicate and 20g of deionized water are added to After reflux for 4 hours under heating conditions, polycondensation at 145°C for 2 hours, and a colorless and transparent solid was obtained after vacuum distillation. Analysis confirmed that the silicone resin consisted of 33% of the formula PhSiO 3 / 2 Unit, 37% molecular formula is MeSiO 3 / 2 unit and 30% of the formula is SiO 4 / 2 A silicone resin with a...

Embodiment 3

[0046] 1. Preparation of hyperbranched silicone resin containing epoxy functional groups

[0047] 1) Under stirring conditions, add 45.00g of γ-glycidoxypropyltriethoxysilane, 2.91g of deionized water and 0.03g of KOH into a three-necked flask, and reflux at 90°C for 8 hours to obtain a solution A;

[0048] 2) Under stirring conditions, dissolve 13.14g of hexamethyldisiloxane in a mixed solvent consisting of 5.00mL of n-butanol and 8.30mL of tetrahydrofuran to obtain solution B;

[0049] 3) Under the conditions of stirring and nitrogen protection, pour solution B into solution A at 90 ° C, and reflux at constant temperature for 7 hours, and obtain the crude product after vacuum distillation;

[0050] 4) After the crude product is dissolved in toluene, the insolubles are filtered off, and after vacuum distillation and vacuum drying, the hyperbranched silicone resin containing epoxy functional groups is obtained,

[0051] 2. Preparation of Silicone Base Resin

[0052] Add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com