Composite fiber material as well as preparation method and application thereof

A composite fiber and organic fiber technology, applied in the field of fiber materials, can solve problems such as difficult to recycle, easy to agglomerate, and organic carriers are easy to be corroded by light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

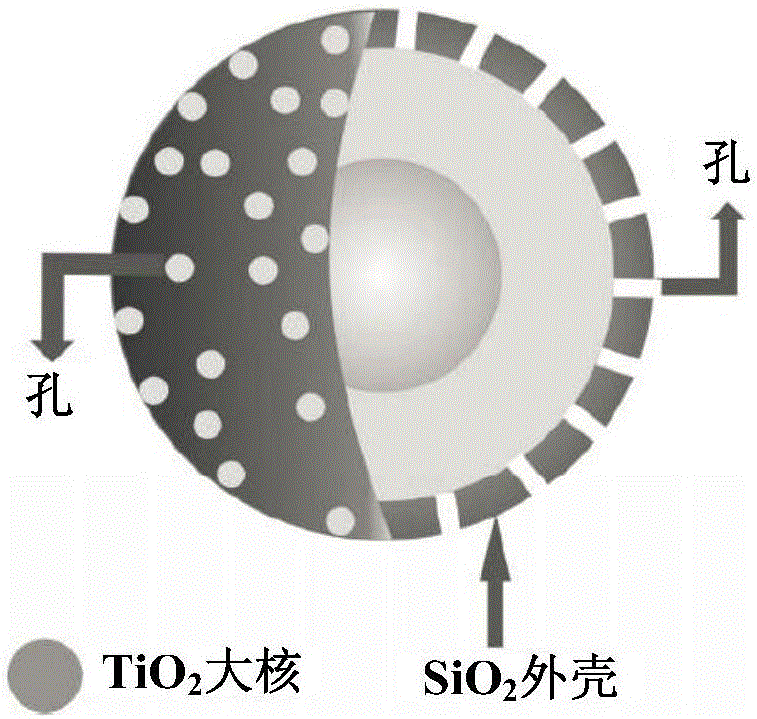

[0059] The present embodiment provides a kind of preparation method of titanium dioxide polyester composite fiber material, comprises the following steps:

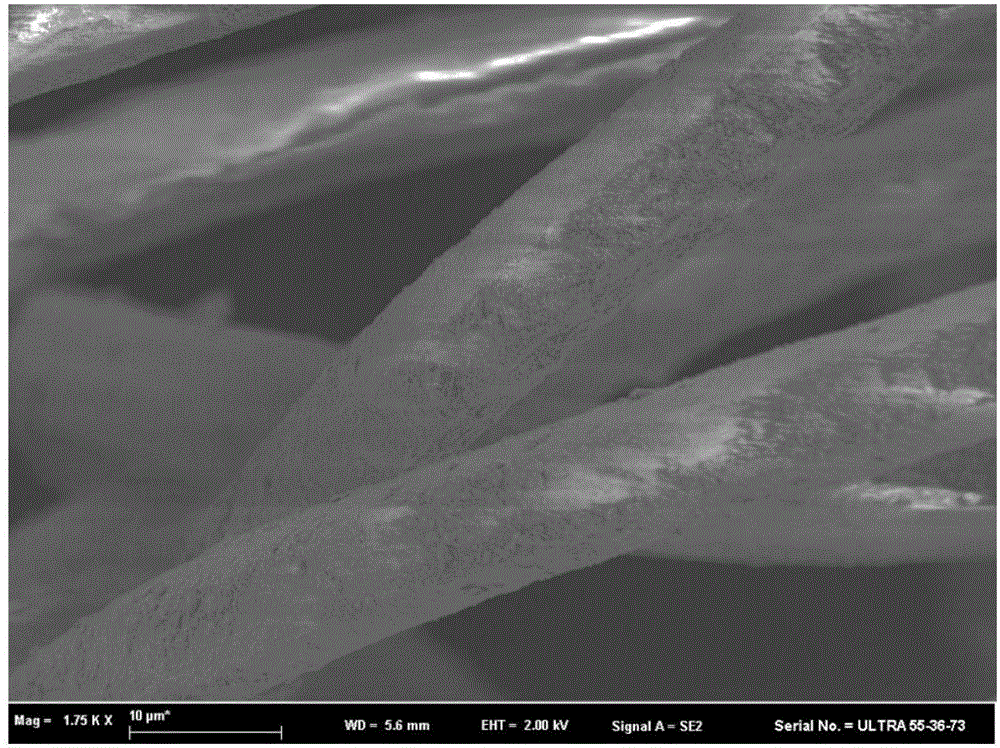

[0060] 15g of titanium dioxide particles with a particle diameter of about 50nm are heated to 100 degrees to obtain high-temperature nano-titanium dioxide particles; 85g of polyester fiber material is placed in a container, and the container is placed in an oven at 70 degrees; Titanium dioxide particles are sprayed into the container with the hot air flow at a spray speed of 0.5m / s, and after circulating in the container for 5 hours, solidify and cool to obtain a titanium dioxide polyester composite fiber material, nano titanium dioxide particles are embedded in polyester fibrous materials such as figure 1 shown.

[0061] After measurement, in the titanium dioxide polyester composite fiber material, the loading capacity of nano titanium dioxide particles is 10% of the polyester fiber material mass; the specific surface ar...

Embodiment 2

[0063] The present embodiment provides a kind of preparation method of titanium dioxide polyamide composite fiber material, comprises the following steps:

[0064] 8g of titanium dioxide particles with a particle diameter of about 100nm were heated to 120 degrees to obtain high-temperature nano-titanium dioxide particles; 92g of polyamide fiber membranes were placed in a container, and the container was placed in an oven at 80 degrees; Titanium dioxide particles are sprayed into the container with the hot air flow at a spray speed of 0.4m / s, and after circulating in the container for 2 hours, solidify and cool to obtain a two-dimensional titanium dioxide polyamide composite fiber material, in which nano titanium dioxide particles are embedded in polyamide fiber membrane.

[0065] After measurement, in the titanium dioxide polyamide composite fiber membrane, the loading capacity of the nanometer titanium dioxide particles is 4.5% of the mass of the polyamide fiber membrane; the...

Embodiment 3

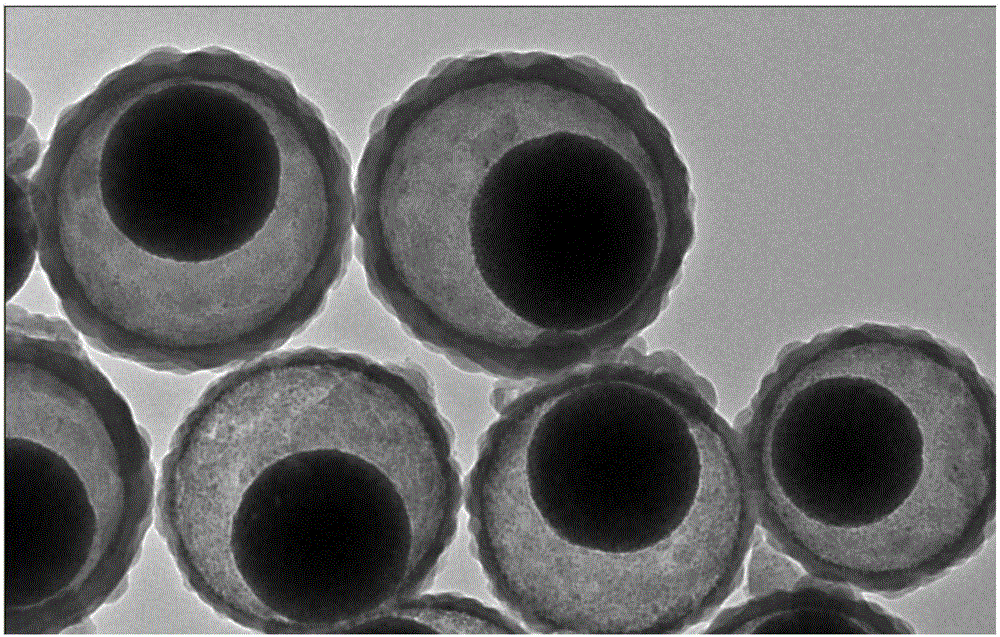

[0067] This embodiment provides a method for preparing a silica-polyacrylonitrile composite fiber material, comprising the following steps:

[0068] 10g of silicon dioxide particles with a particle size of about 120nm are heated to 150 degrees to obtain high-temperature nano-silica particles; 90g of polyacrylonitrile fibers are placed in a container, and the container is placed in an oven at 80 degrees; The high-temperature nano-silica particles are sprayed into the container with the hot air flow at a spray speed of 0.3m / s, and after circulating in the container for 3 hours, they are solidified and cooled to prepare a one-dimensional silica-polyamide composite. In the fiber material, the nano silicon dioxide particles are embedded in the polyacrylonitrile fiber material, and the one-dimensional silicon dioxide polyacrylonitrile composite fiber material is woven into a three-dimensional silicon dioxide polyacrylonitrile composite fiber net.

[0069]After measurement, in the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com