Low-reflection and high-absorption electromagnetic shielding polymer composite material with gradient electric conduction-uniform heat conduction dual-functional network

An electromagnetic shielding and composite material technology, applied in shielding materials, magnetic field/electric field shielding, carbon compounds, etc., can solve the problems affecting the thermal conductivity of materials, low thermal conductivity, heat accumulation, etc., and achieve low reflection and high absorption while optimizing and thermally conducting. The effect of simultaneous optimization of performance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

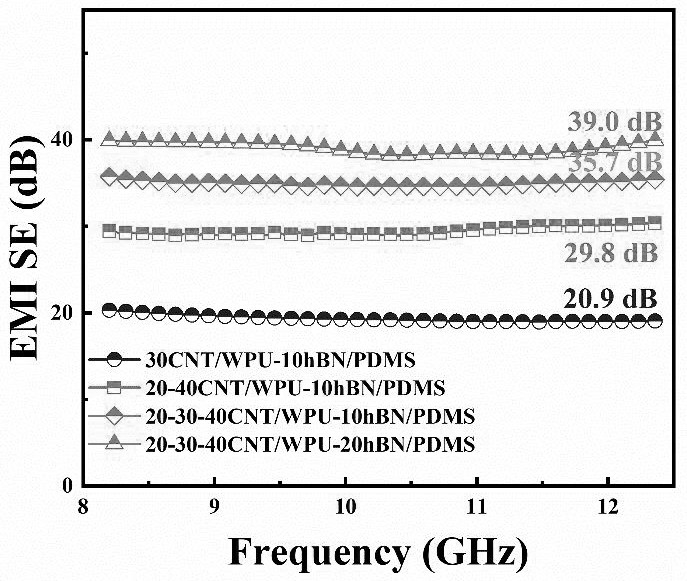

[0030] A method for preparing a carbon nanotube-based electromagnetic shielding polymer composite material with a double-layer gradient conduction-uniform heat conduction dual-functional network, comprising the following steps:

[0031] Step 1, preparation of double-layer gradient conductive carbon nanotube foam, including:

[0032] Weigh 60mg of carbon nanotubes, and blend them with 0.69g of water-based polyurethane (solid content is 35wt%) in 15ml of deionized water, and ultrasonically disperse for 30min to prepare a CNT-20 dispersion; weigh 120mg of carbon nanotubes, mix with 0.51g of water-based Polyurethane was blended in 15ml of deionized water and ultrasonically dispersed for 30 minutes to prepare a CNT-40 dispersion; the two dispersions were poured into the mold in sequence, frozen and shaped in liquid nitrogen, and the interface was assisted by heat flow to make the cells connected , a double-layer gradient conductive carbon nanotube foam with a thickness of 4mm was o...

Embodiment 2

[0040] A method for preparing a carbon nanotube-based electromagnetic shielding polymer composite material with a three-layer gradient conduction-uniform heat conduction dual-functional network, comprising the following steps:

[0041] Step 1, preparation of three-layer gradient conductive carbon nanotube foam, including:

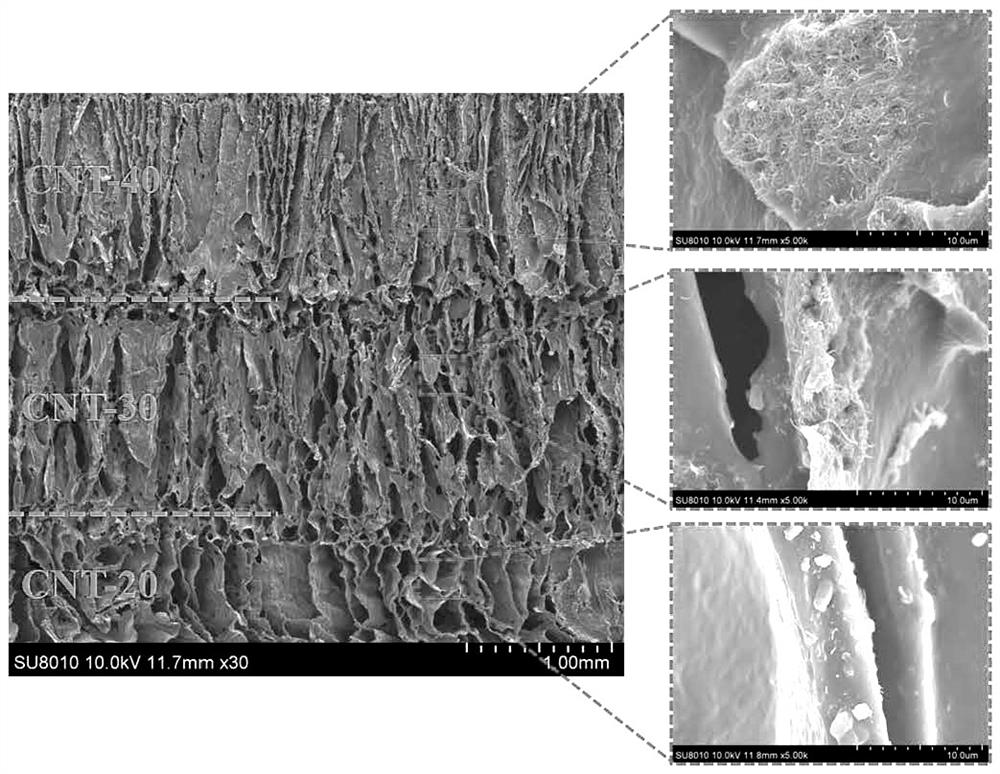

[0042] Weigh 40mg of carbon nanotubes, and blend them with 0.46g of water-based polyurethane (solid content is 35wt.%) in 10ml of deionized water, and ultrasonically disperse for 30min to prepare a CNT-20 mixed solution; weigh 60mg of carbon nanotubes, and mix with 0.4g Water-based polyurethane was blended in 10ml of deionized water, ultrasonically dispersed for 30min to prepare CNT-30 dispersion liquid; 80mg of carbon nanotubes were weighed, blended with 0.34g of aqueous polyurethane in 10ml of deionized water, and ultrasonically dispersed for 30min to prepare CNT-30 40 dispersion liquid; pour the three dispersion liquids into the mold in sequence, freeze ...

Embodiment 3

[0050] A method for preparing a carbon nanotube-based electromagnetic shielding polymer composite material with a three-layer gradient conduction-uniform heat conduction double network, comprising the following steps:

[0051] Step 1, preparation of three-layer gradient conductive carbon nanotube foam, including:

[0052] Weigh 40mg of carbon nanotubes, and blend them with 0.46g of water-based polyurethane (solid content is 35wt.%) in 10ml of deionized water, and ultrasonically disperse for 30min to prepare a CNT-20 mixed solution; weigh 60mg of carbon nanotubes, and mix with 0.4g Water-based polyurethane was blended in 10ml of deionized water, ultrasonically dispersed for 30min to prepare CNT-30 dispersion liquid; 80mg of carbon nanotubes were weighed, blended with 0.34g of aqueous polyurethane in 10ml of deionized water, and ultrasonically dispersed for 30min to prepare CNT-30 40 dispersion liquid; pour the three dispersion liquids into the mold in sequence, freeze and shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com