Preparation method of electromagnetic composite hollow microspheres

An electromagnetic composite, hollow microsphere technology, applied in the preparation of microspheres, microcapsule preparations, magnetic properties of inorganic materials, etc., can solve the problems of easy falling off of magnetic particles, high density, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

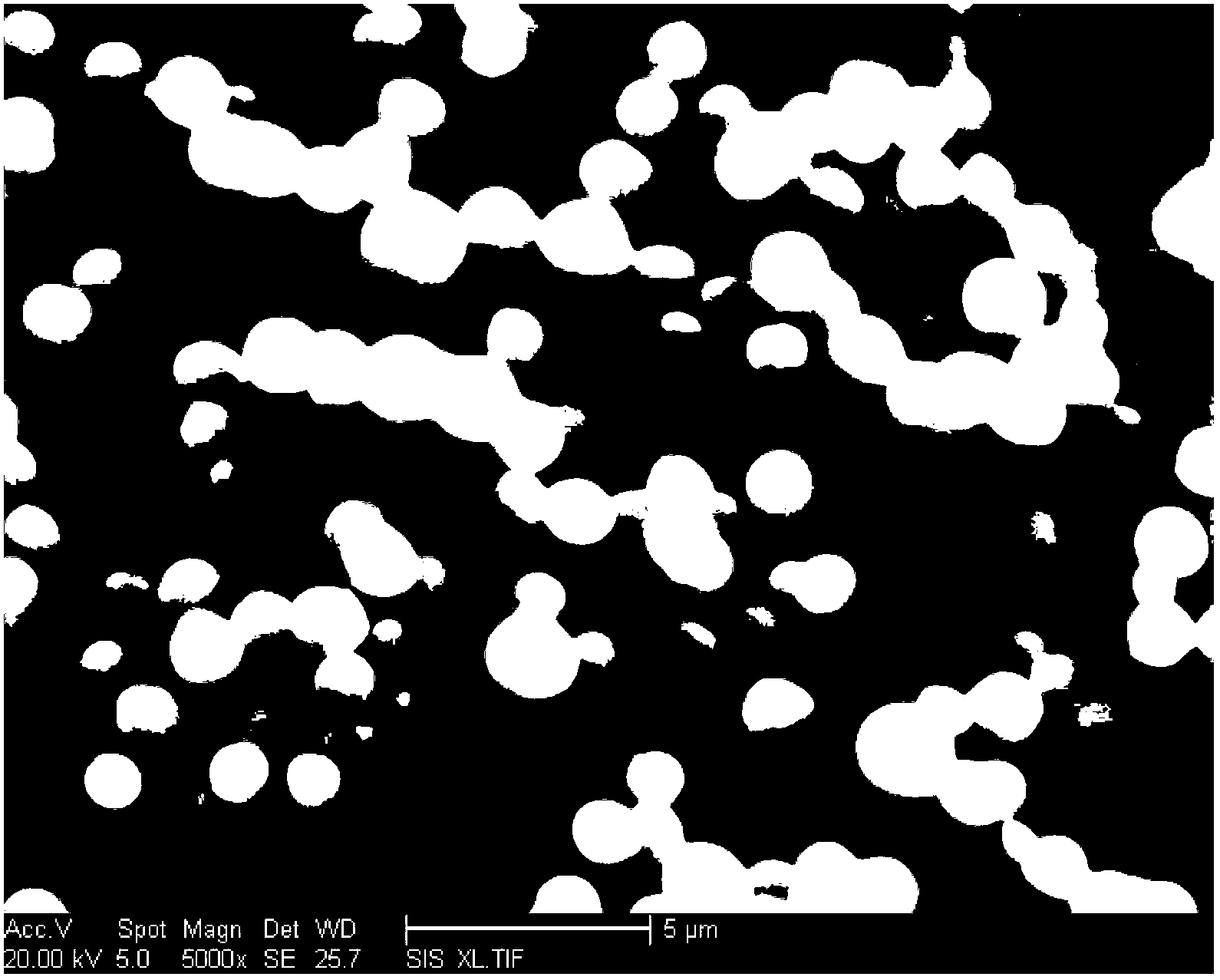

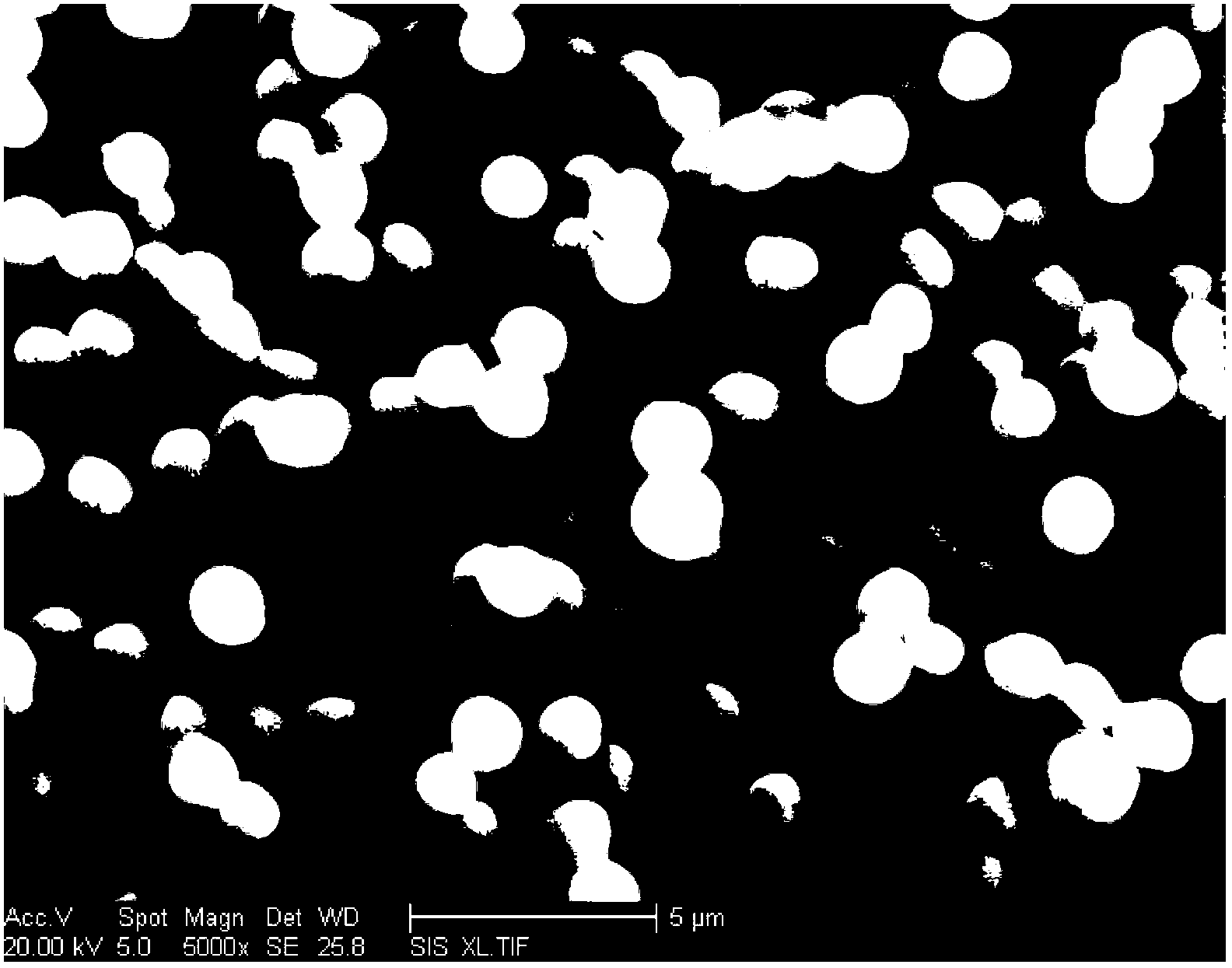

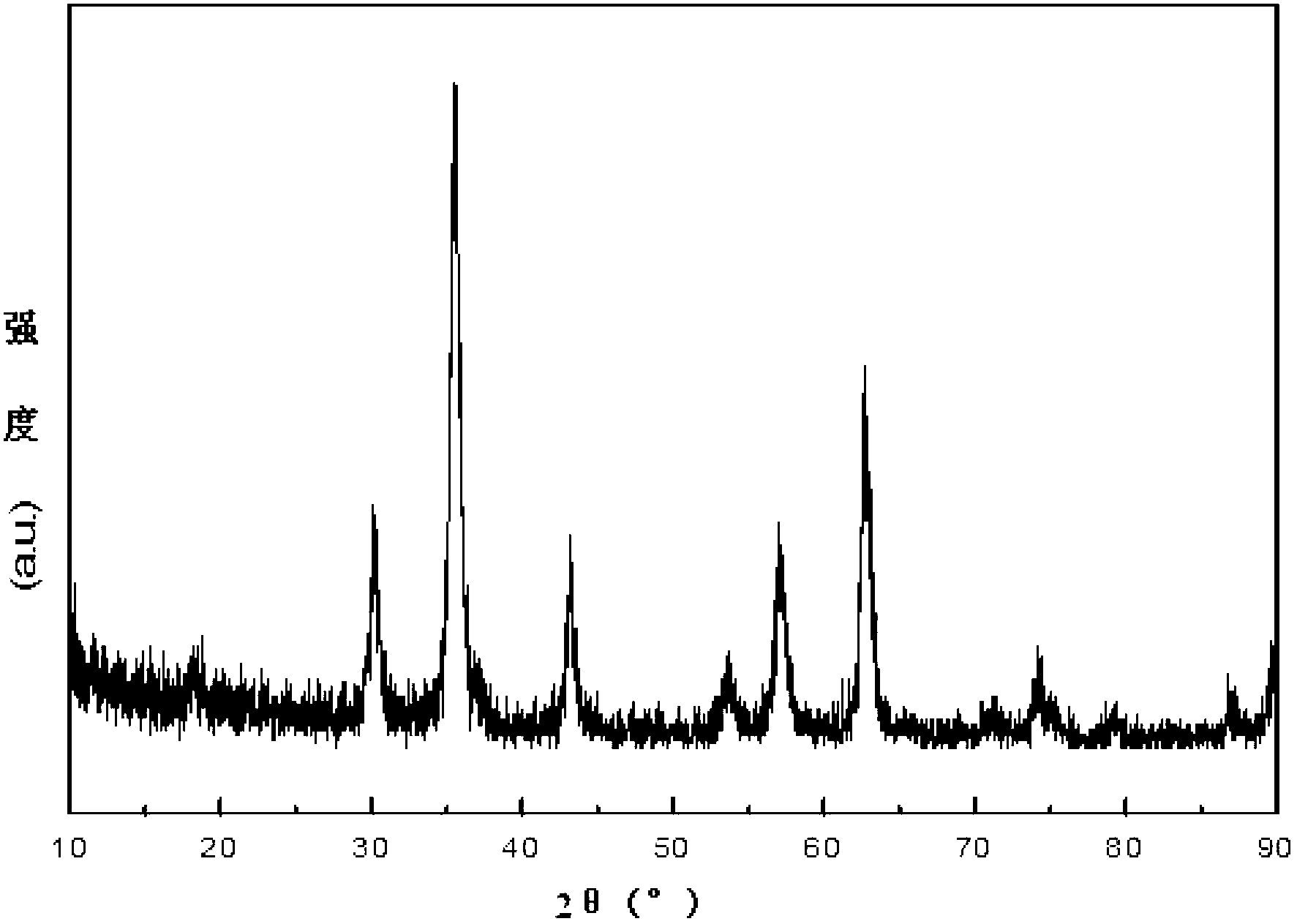

[0019] Specific implementation mode one: the preparation method of the electromagnetic composite hollow microspheres of this embodiment is implemented according to the following steps:

[0020] 1. Add 0.4-0.8g of AIBN (azobisisobutyronitrile), 63-127g of ethanol with a mass concentration of 95%, 3.3-6.7g of distilled water and 1.0-2.0g of PVP (polyvinylpyrrolidone) In the reactor, after stirring evenly, add 13.3-26.7g of St (styrene), disperse evenly, and react at a reaction temperature of 70-75°C, a stirring speed of 90-110r / min, and nitrogen protection for 10-14h. Get PS (polystyrene) microspheres;

[0021] 2. Disperse the PS (polystyrene) microspheres obtained in step 1 in sulfuric acid with a mass concentration of 98%, sulfonate at 35-50°C for 1-4 hours, then wash with ethanol for 2-4 times, and then wash with water After centrifugation, the pH of the supernatant was 6, and freeze-dried to obtain SPS microspheres with sulfonic acid groups on the surface;

[0022] Three, ...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that 2 g of PS (polystyrene) microspheres in Step 2 are dispersed in 40 ml of sulfuric acid with a mass concentration of 98%. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0029]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the molar ratio of step three is 1.5:1 FeCl 3 ·6H 2 O and FeCl 2 4H 2 O was dissolved in distilled water. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation susceptibility | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com