Device for pushing and feeding tail materials in silo

A technology of pushing device and material pushing device, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems that affect the processing quality of subsequent processes, cannot control the state of the tailings of the storage cabinet, and the flow rate of the cabinet is reduced, so as to eliminate unsafe Hidden dangers, solution to tailing instability, ingenious structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

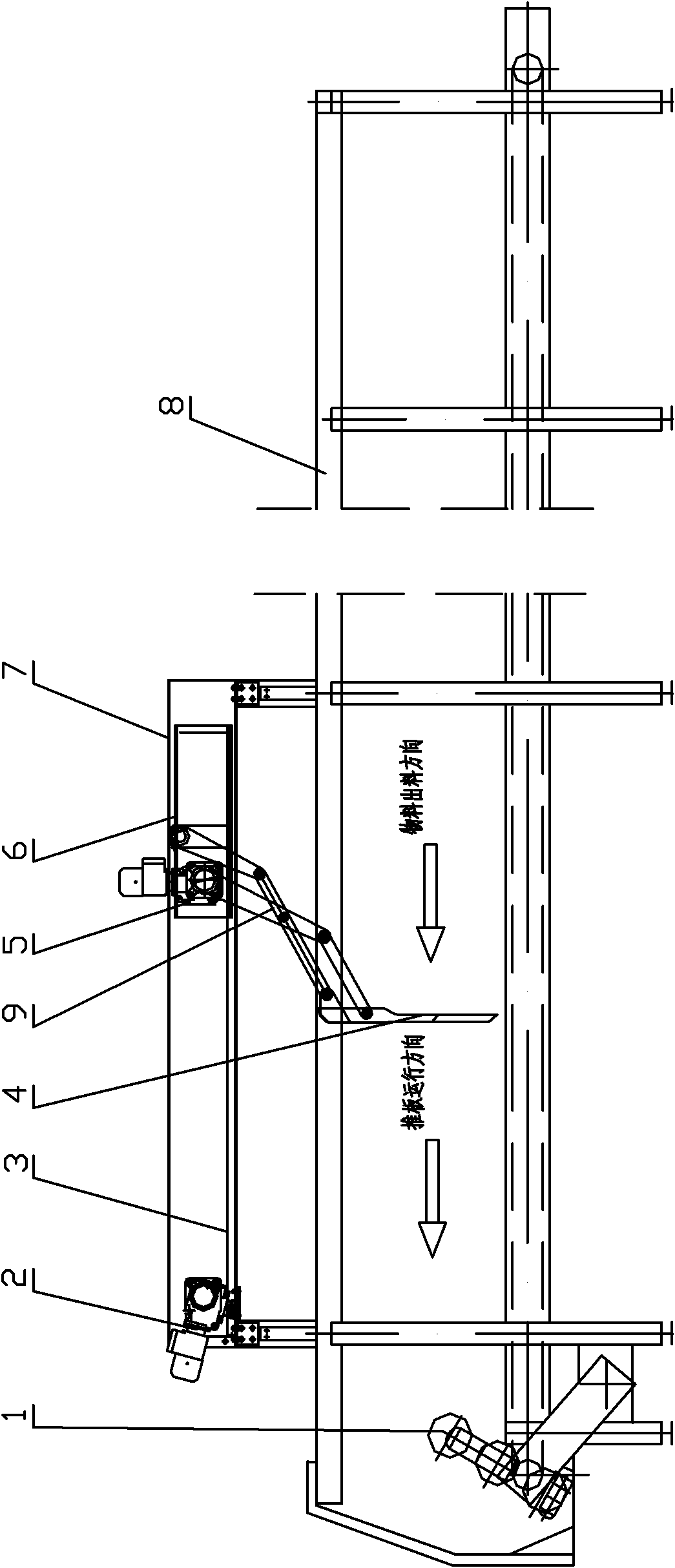

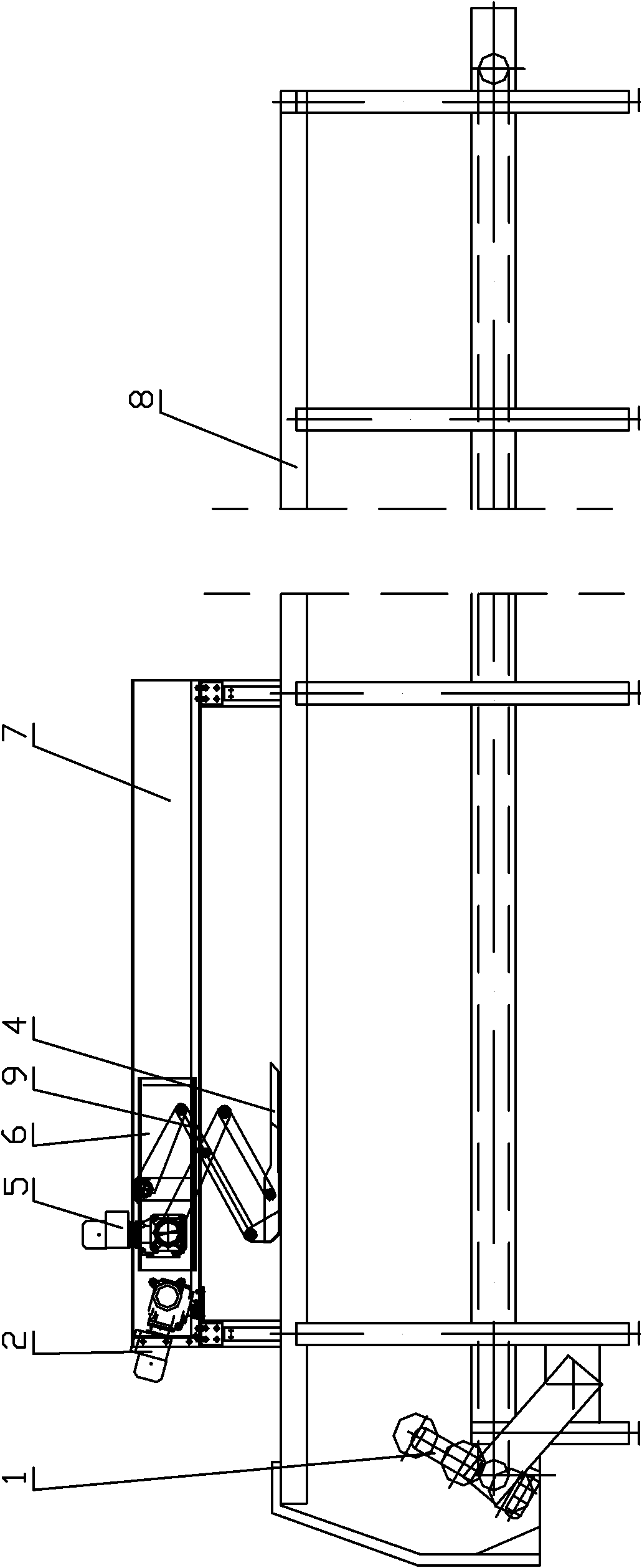

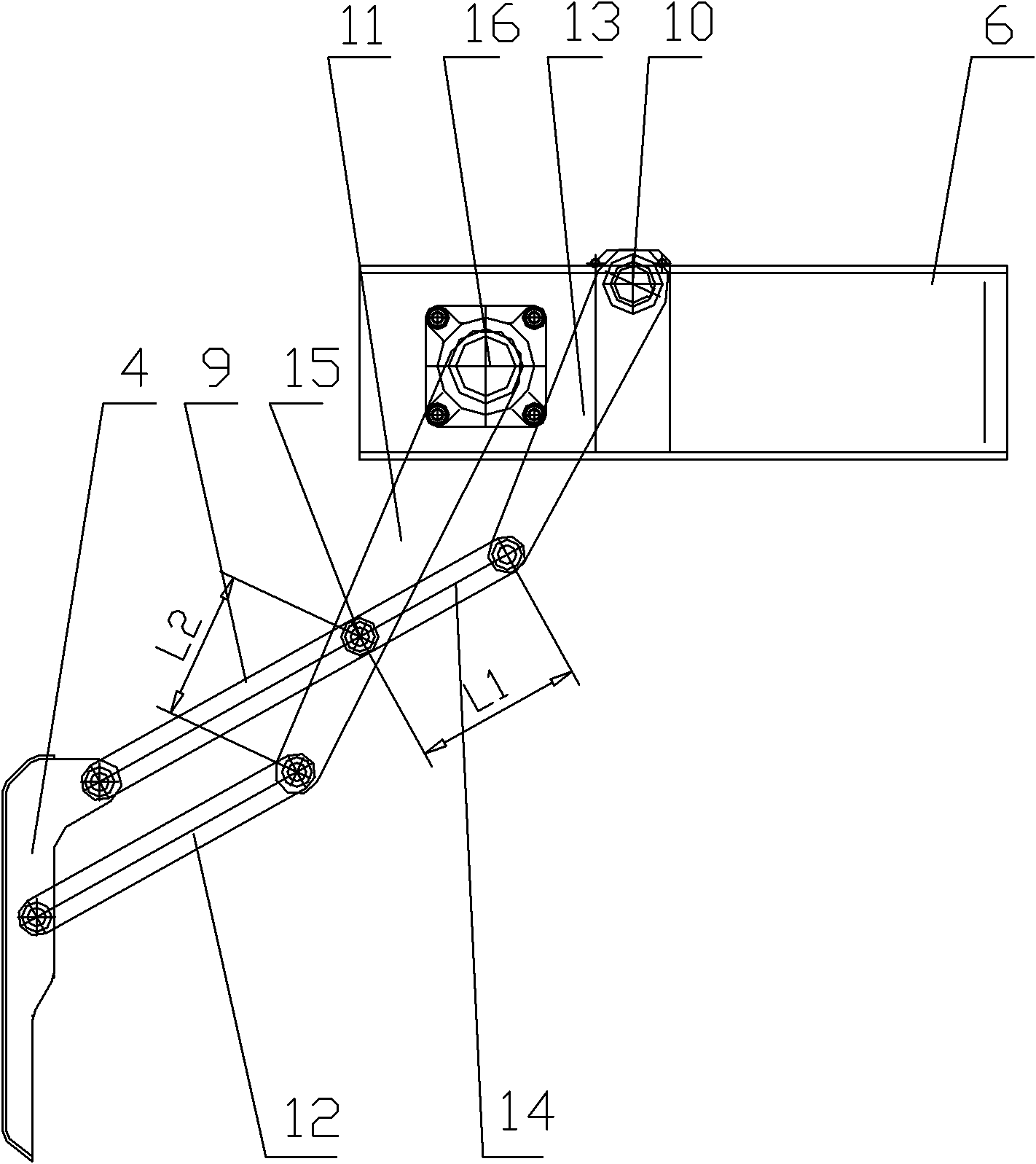

[0011] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. as attached figure 1 As shown, the device is arranged on the top of the storage cabinet 8, the bottom of the frame 7 is provided with a slide rail 3, and the pushing device 6 is arranged on the slide rail 3, and can slide along the The rail 3 moves back and forth, and the reciprocating motor 2 is connected with the pushing device 6 through a toothed transmission chain. As shown in the figure, the pushing device 6 is in the tailing state, and the pushing device 6 runs to the rear of the tailing, and its four-link hinge pushing plate mechanism 9 is in an open state under the action of the turning motor 5, and the pushing plate 4 is put down. To the vertical position, driven by the reciprocating motor 2, driven by the reciprocating motor 2 of the push mechanism, the material is pushed at a speed greater than the bottom belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com