Ink-jet machine achieving remote real-time code ink jetting based on GPRS

An inkjet printer and inkjet technology, applied in the field of inkjet printers, can solve the problems of unsafe hidden dangers, harmful respiratory system and other body organs, regular maintenance and maintenance, etc., to reduce labor costs, reduce failure rates, and ensure personal safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

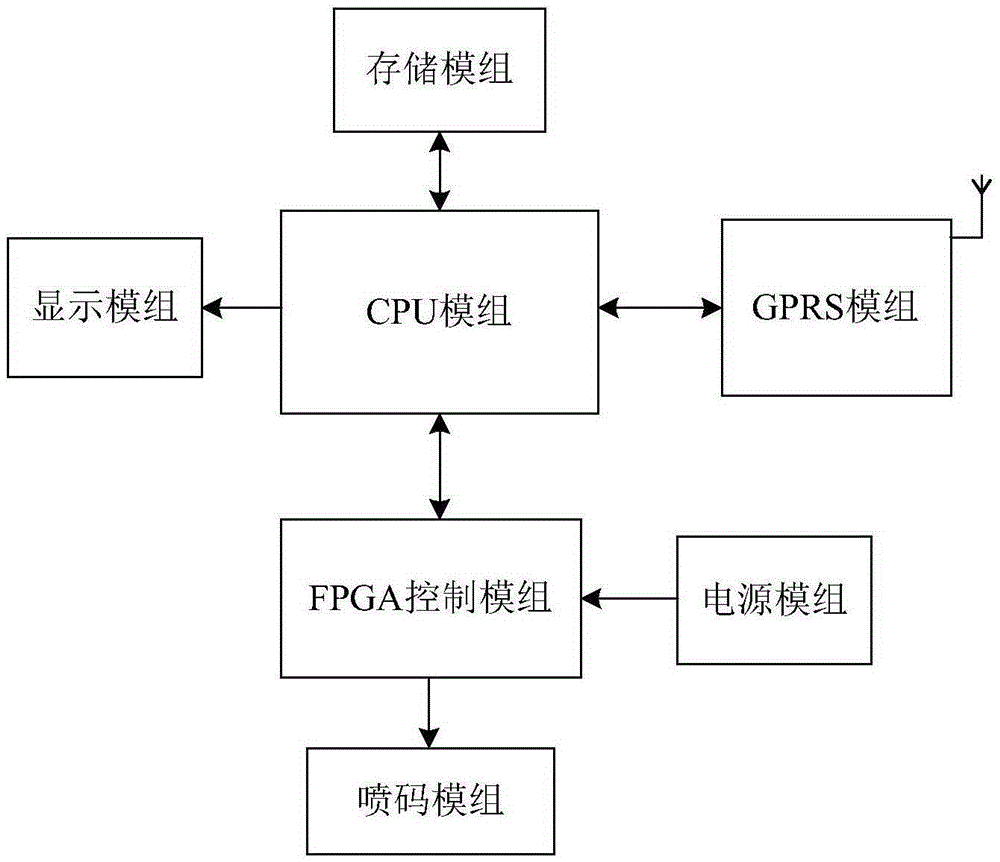

[0028] Such as figure 1 Shown, the hardware part of the present invention is by CPU module, the GPRS module that links to each other with CPU module and FPGA control module, the coding module that links to each other with FPGA control module and power supply module, links to each other with CPU module Composed of storage modules and display modules.

[0029] Among them, the CPU module adopts TIA8AM3358 processor, the CPU module communicates with the GPRS module through the serial port, the CPU module connects with the FPGA control module through the SPI bus, and the function of the CPU module is to send data to the The management terminal at the end receives the control command sent by the management terminal, and then decodes the command and sends it to the FPGA control module to execute the corresponding command.

[0030] The GPRS module adopts SIM300 module, which has triple-frequency GSM (Global Mobile Communication System) and GPRS functions, embedded TCP / IP protocol, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com