Speed measurement control device for motor

A control device and speed measurement technology, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of increased installation space, no speed measurement device, and increased motor operating noise, and is convenient for packaging and transportation. , The effect of eliminating unsafe hidden dangers and accurate speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

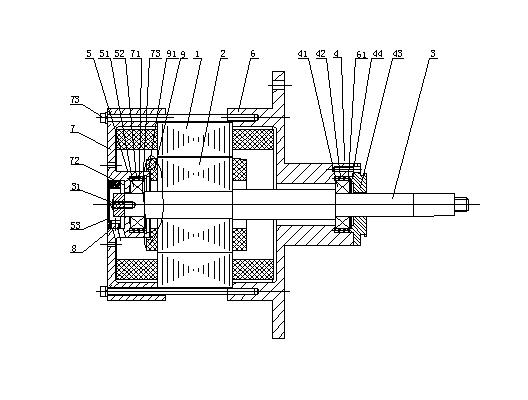

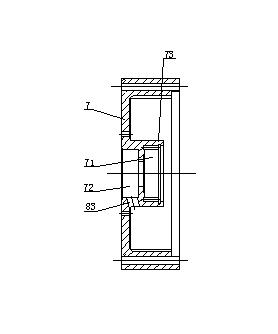

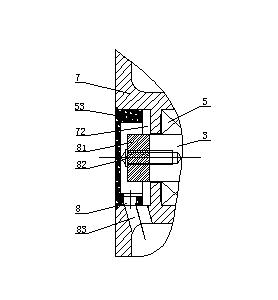

[0029] As shown in the accompanying drawings, a speed measurement control device for a motor includes a motor shaft 3 interspersed in the center of the stator core 1 and the rotor core 2, and the motor shaft 3 is respectively fixed to the motor through an upper bearing device 4 and a lower bearing device 5. Among the upper end cover 6 and the lower end cover 7 of the motor, the upper bearing device 4 includes an upper end cover bearing 41 fixed on the motor main shaft 3, and the upper end cover bearing 41 is arranged in the recessed platform 61 of the upper end cover 6 of the motor, and the upper end cover bearing of the recessed platform 61 41 The upper bearing elastic element 42 is arranged radially, and the upper sealing cover plate 43 is arranged axially of the upper bearing elastic element 42; the lower bearing device 5 includes a lower end cover bearing 51 fixed on the motor main shaft 3, and the lower end cover bearing 51 is arranged on the lower end cover of the motor 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com