Assemble comb-type bridge extension joint

An expansion device and assembled technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problem of unsuitable expansion joint devices, and achieve the effect of eliminating unsafe hidden dangers, low cost and low height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

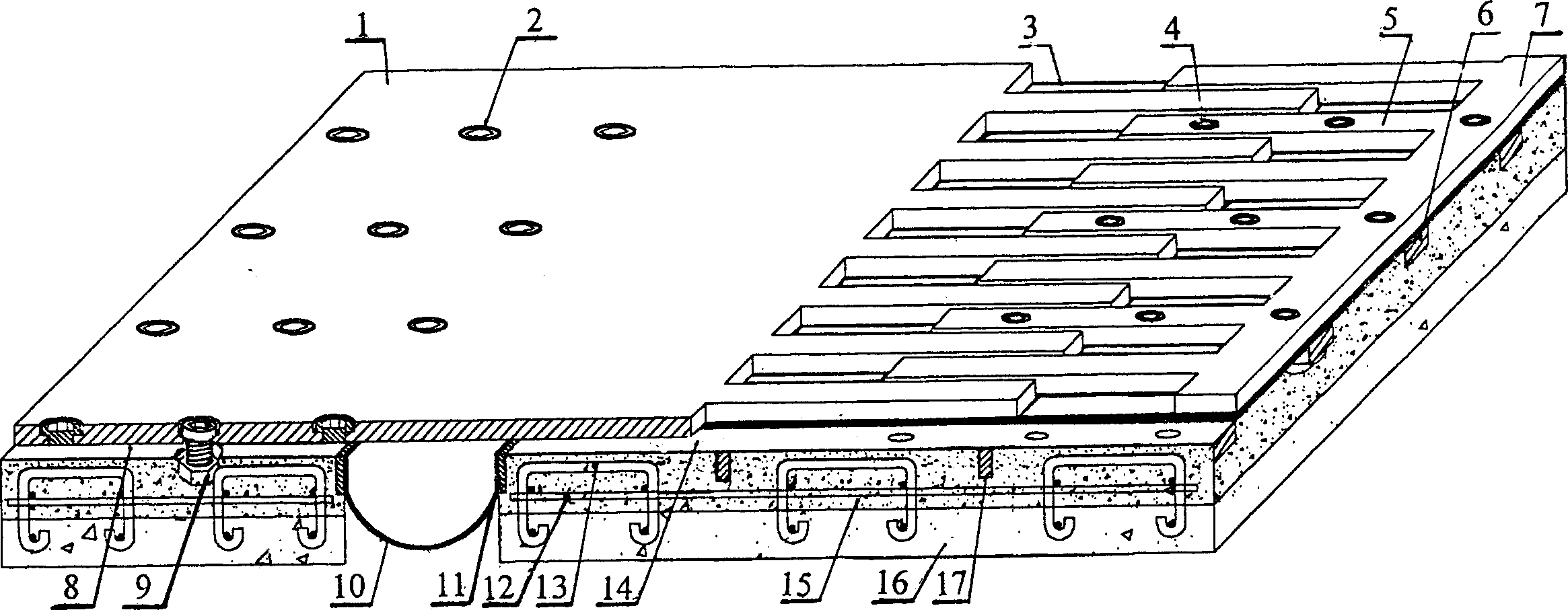

[0022] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

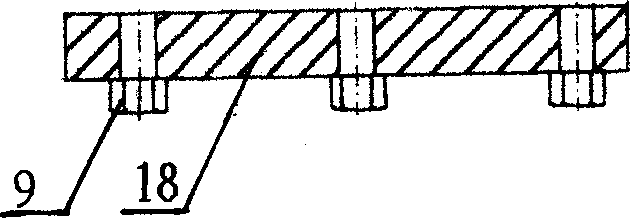

[0023] Horizontal support plate 6,18, for the elongated shape of 1~6 through holes 2 on the upper, lower end surface through hole 2 corresponding place, welding is fixed with nut 9, and through hole 2 number is determined by its length.

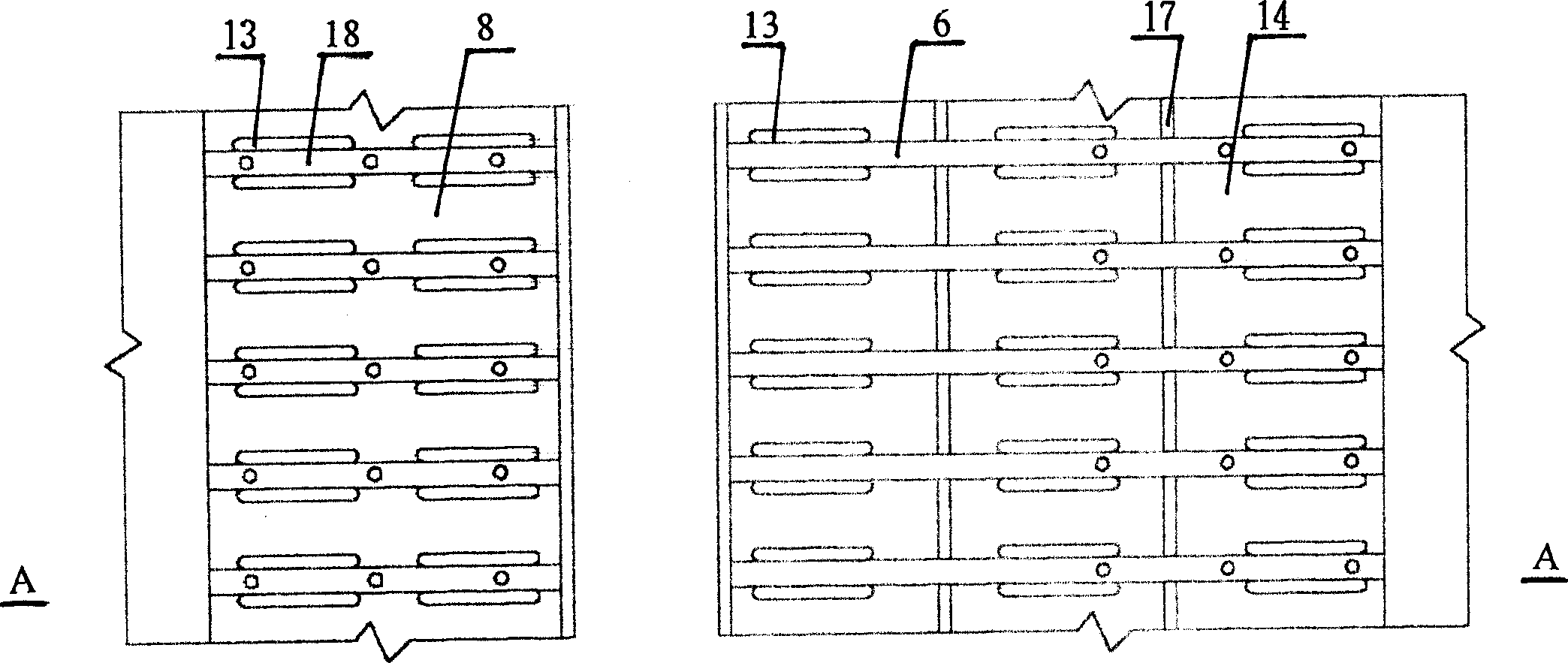

[0024] The vertical support plates 11, 17 are elongated.

[0025] On both sides of the expansion joint, two steel bars 13 with horizontal and crack-proof mesh bars 12 are arranged in parallel in a group, arranged in sequence, embedded in the beam body 16, and a horizontal support plate 6, 18 is clamped therebetween. It is welded and fixed on both sides of steel bar 13. During construction, due to the dislocation caused by the pre-embedded steel bars 13, additional steel bars can be added to weld and fix the transverse support plates 6, 18 and the pre-embedded steel bars 13 into one for remediation.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com