High-strength pretightening force compressible glass fibre reinforced plastic anchor rod

A technology of glass fiber reinforced plastics and pre-tightening force, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problems of poor anchoring effect and low tensile strength of bolts, and achieve the effect of avoiding damage and improving torsional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

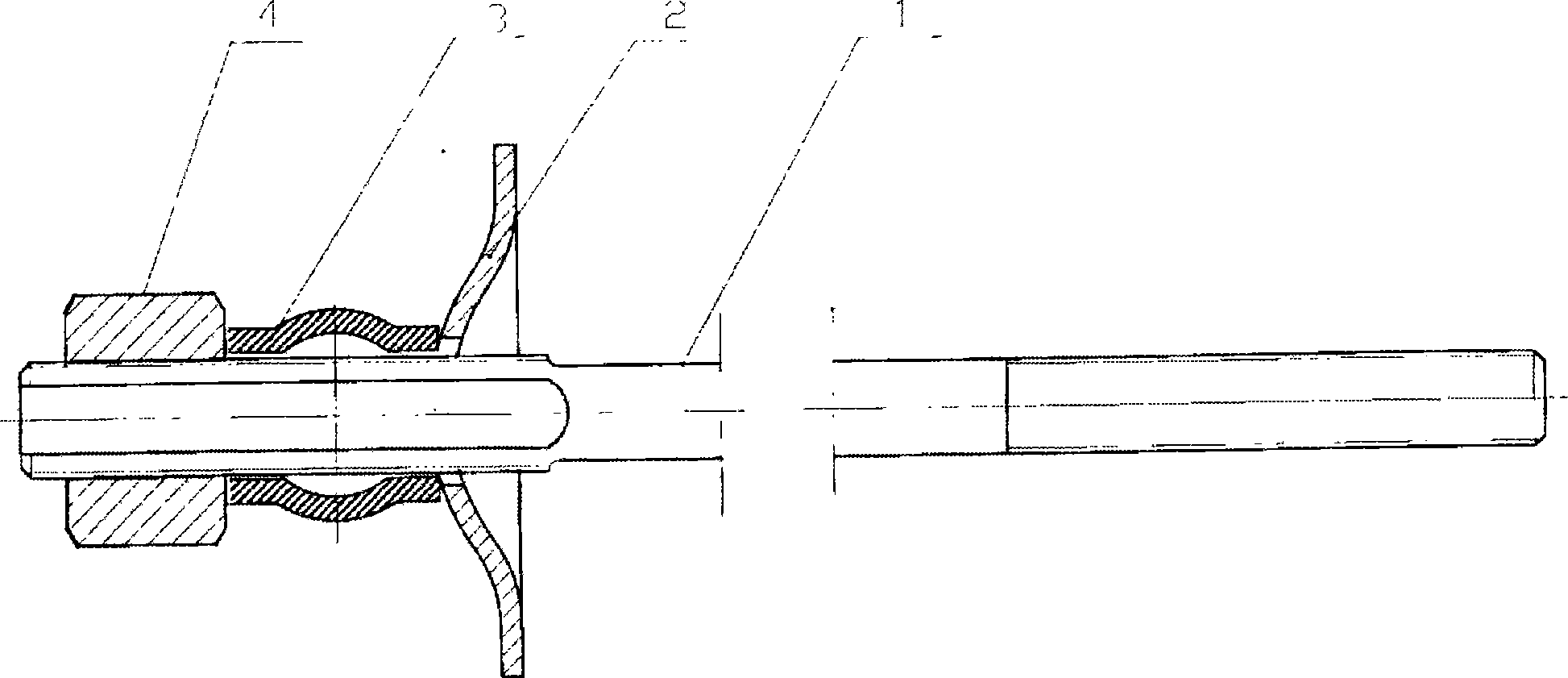

[0009] When in use, first use the anchor drill to drill holes, then put the resin anchoring agent into the hole, and then install the glass fiber reinforced plastic anchor rod, etc. After the resin is cured, install the tray 2, the pressure ring 3, the nut 4, and tighten the nut 4. When the anchor rod is stressed during the support process, let the pressure ring 3 bear the pressure from both ends. When the pressure reaches a certain level, let the pressure ring 3 begin to deform, and the tray 2 moves backward, which also causes a part of the roadway wall to ground. compressive stress, effectively protecting the FRP anchor from breaking due to excessive pressure, the anchor can only slide back and forth in the tray 2, and cannot rotate; Let the pressure ring 3 pass into the tray 2, and then pass through the tray 2 and to the coal wall, thereby avoiding damage to the tail of the rod body due to excessive pre-tightening force applied to the nut 4, and improving the torsional stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com