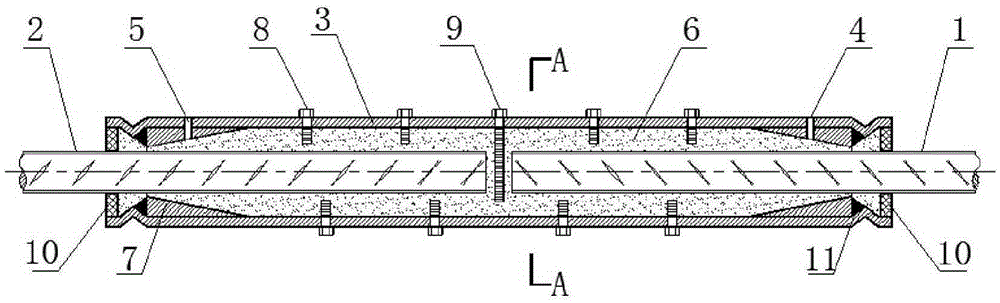

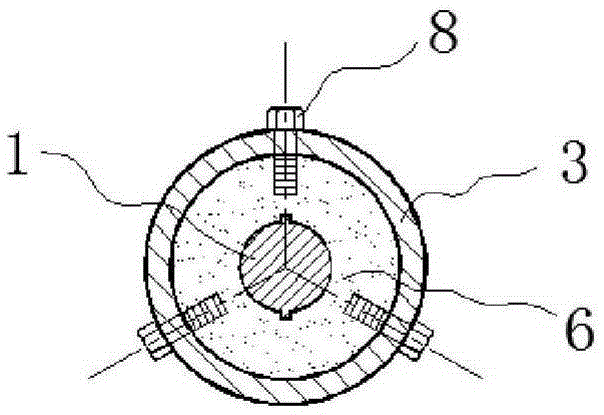

Fully grouted sleeve with built-in cone

A full grouting and sleeve technology, applied in structural elements, building components, building reinforcements, etc., can solve problems such as high technical requirements, difficult processing, and complex processing, achieve broad engineering application prospects, improve restraint ability, reduce The effect of anchoring length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The full-grouting sleeve with a built-in cone is embedded with a cone, so that the inner diameter of the sleeve shrinks along the direction of the hole. When the steel bar is under the action of tension, the cement grout inside the sleeve has an Sliding tendency, the cone inside the casing makes the grouting material in a triaxial stress state, thereby greatly enhancing the bonding force between the high-strength grouting material and the steel bar, and ensuring that the steel bar does not undergo bond-slip damage.

[0025] In order to prevent the embedded cone from being pulled out when the steel bar is stretched, the sleeve corresponding to the outer end of the cone is rolled to reduce the inner diameter of the sleeve, and the cone and sleeve are fixed by welding.

[0026] In order to ensure that the steel bar can be inserted into the sleeve, the minimum inner diameter of the embedded cone should be slightly larger than the diameter of the steel bar.

[0027] By setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com