Anti-skid tunnel structure and construction method thereof

A technology of tunnel structure and construction method, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as large project investment and difficult construction, and achieve the effects of avoiding diseases, improving safety, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

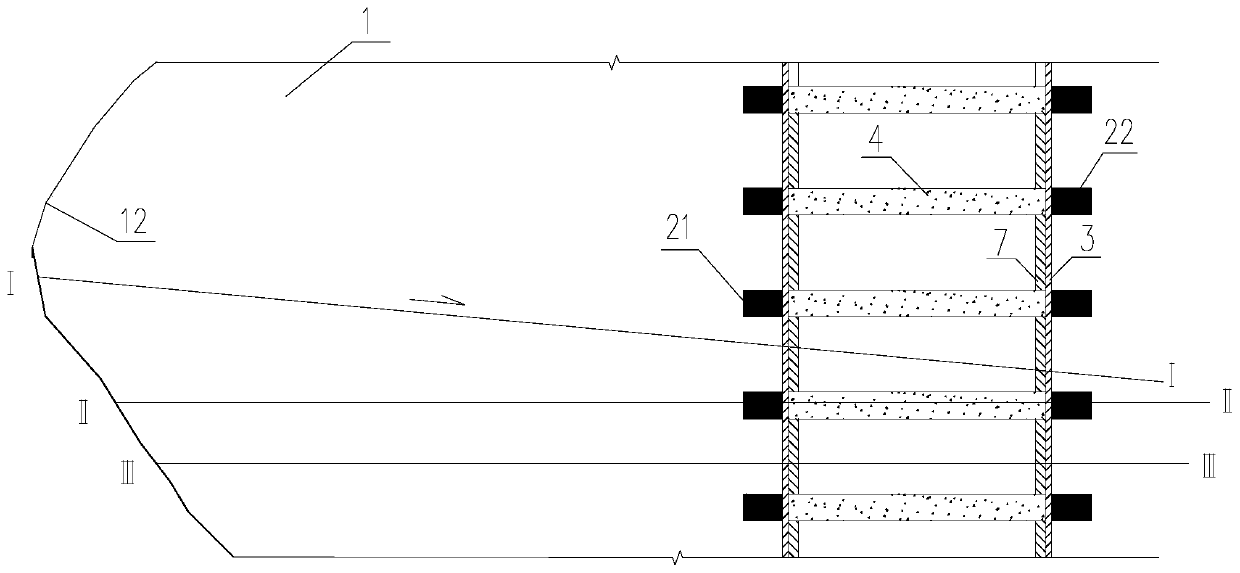

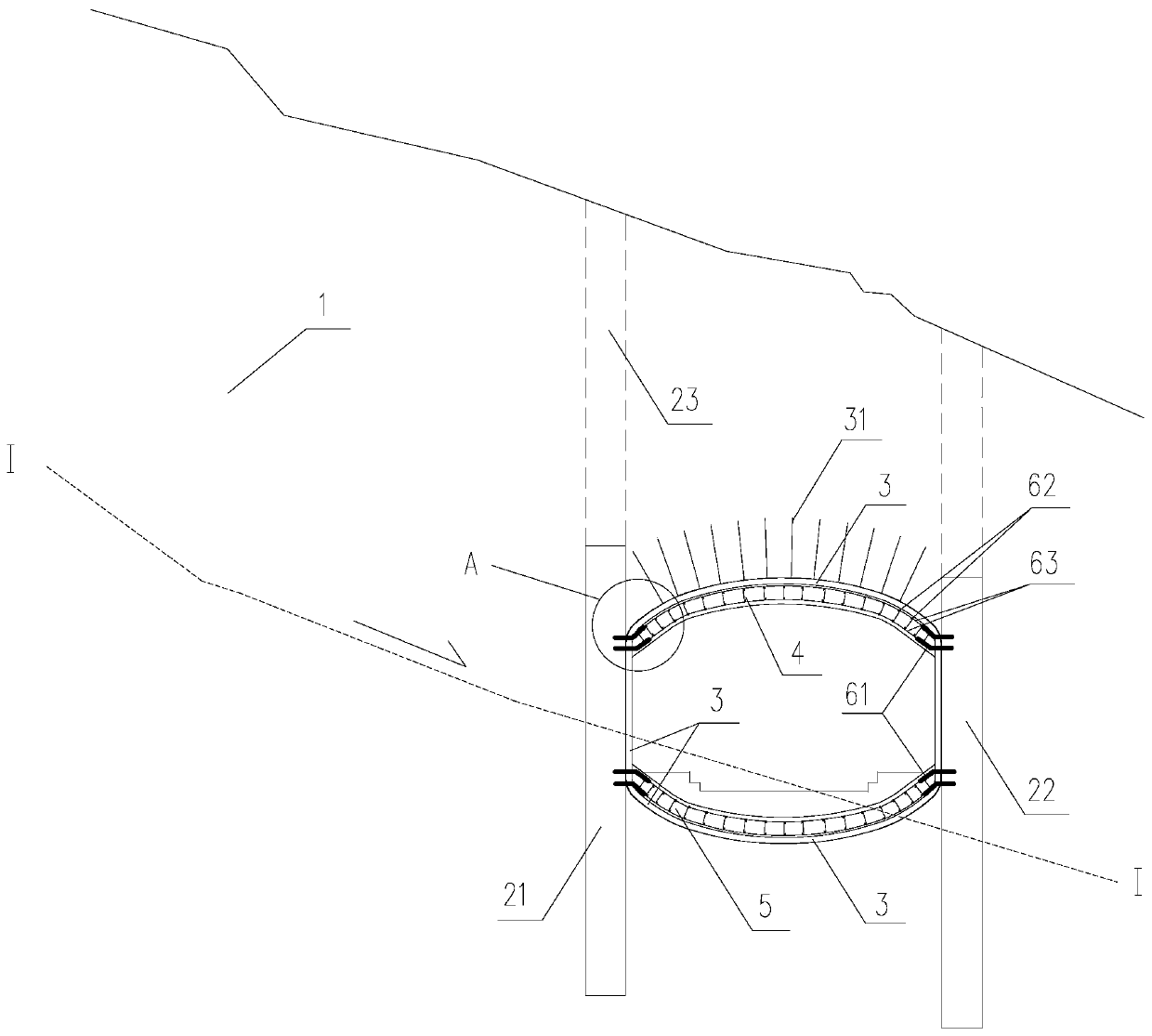

[0048] Such as Figure 1-Figure 5 Shown, a kind of anti-sliding tunnel structure comprises the tunnel structure that passes in the landslide body 1, and the vault and the inverted arch of the tunnel structure are respectively provided with a plurality of upper connecting beams 4 and lower connecting beams 5, and the upper connecting beams The beams 4 and the lower connecting beams 5 are evenly spaced along the direction of the tunnel structure, wherein Figure 1-Figure 3 Ⅰ-Ⅰ in the figure is the main axis direction of the landslide, and the direction of the arrow is the downhill direction of the landslide. figure 1 The middle mark 12 is a landslide surface.

[0049] Both sides of the tunnel structure are respectively provided with a plurality of upper anti-slide piles 21 and lower anti-slide piles 22, and the upper anti-slide piles 21 and the lower anti-slide piles 22 are all along the tunnel structure. The trend direction is evenly spaced, and the top surfaces of the upper ...

Embodiment 2

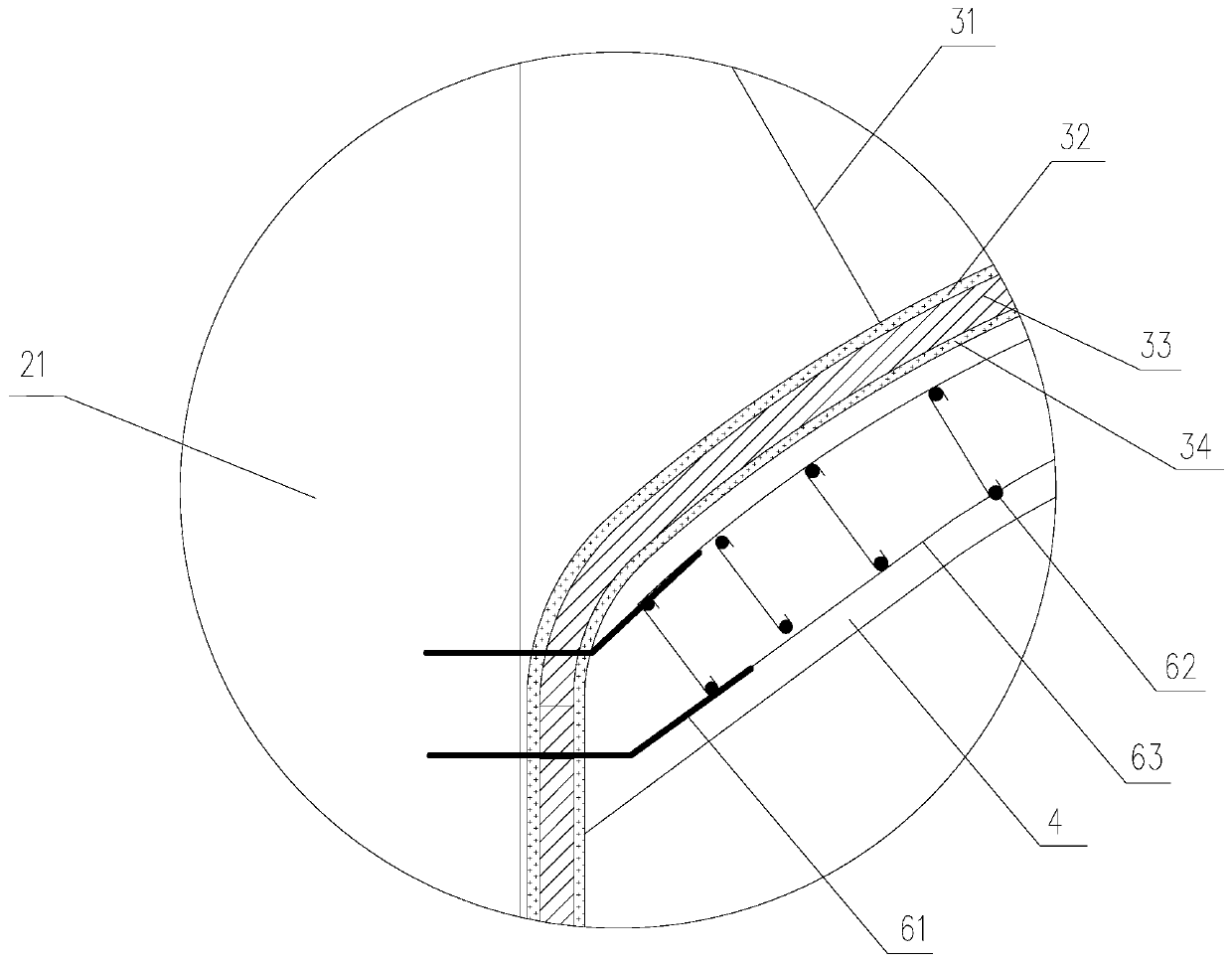

[0063] Such as Figure 6-Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the primary support 3 and the secondary lining 7 are arranged along the entire length of the tunnel, and the upper connecting beam 4 and the lower connecting beam 5 are arranged on the The inner side of the secondary lining 7 is fixedly connected with the secondary lining 7. Specifically, the secondary lining 7 is pre-embedded with a second connecting steel bar 62 arranged in the vertical plane, and the secondary lining The inner steel bar 64 is connected with the connecting beam steel bar 63 , and further connects the secondary lining 7 with the upper connecting beam 4 and the lower connecting beam 5 . In this way, the reinforcement strength of the anti-sliding tunnel structure is stronger than that of Embodiment 1, but compared with Embodiment 1, certain engineering costs will be increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com